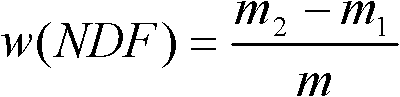

Method for determining neutral detergent fiber content in pasture

A neutral detergent fiber and measurement method technology, applied in the direction of weighing by removing certain components, can solve the problems of difficulty in ensuring timeliness, cumbersome experimental steps, expensive equipment and filter bags, etc., and the conditions for determination are easy Satisfies, simplifies the configuration process, and improves the effect of timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1, the mensuration of alfalfa neutral detergent fiber content

[0043] (1) After cutting the alfalfa to 1-2 cm, place it in a dry and ventilated environment to dry naturally. The air-dried samples were ground with a food grinder to a particle size of 18 mesh.

[0044] (2) Put 1.03 g of the above-mentioned alfalfa sample and 100 ml of neutral washing liquid into a storage bottle (volume 150 ml); screw on the storage bottle cap, and tighten it properly to maintain internal and external ventilation. Then, put the bottle into the pressure cooker, add water to the neck of the pot (the place where the mouth of the bottle is convex), and put it on the fire. After boiling, adjust to a weak boiling state and keep for 10 minutes to degas. Do not cover the pressure cooker during this process.

[0045] (3) Tighten the cap of the preservation bottle, add water to the neck of the bottle, cover the lid of the pressure cooker and put it on the fire, keep the pressurized s...

Embodiment 2

[0050] Embodiment 2, the mensuration of Leymus chinensis neutral detergent fiber content

[0051] (1) After cutting the Leymus chinensis to 1-2 cm, place it in a dry and ventilated environment to dry naturally. The air-dried samples were ground with a food grinder to a particle size of 40 mesh.

[0052] (2) Put 0.97g sample of Leymus chinensis above and 100ml of neutral detergent into a preservation bottle (volume 150ml); screw on the cap of the preservation bottle, and tighten it moderately to maintain internal and external ventilation. Then, put the bottle into the pressure cooker, add water to the neck of the pot (the place where the mouth of the bottle is convex), and put it on the fire. After boiling, adjust to a weak boiling state and keep for 10 minutes to degas. Do not cover the pressure cooker during this process.

[0053] (3) Tighten the cap of the preservation bottle, add water to the neck of the bottle, cover the lid of the pressure cooker and put it on the fire, ...

Embodiment 3

[0058] Embodiment 3, the mensuration of white clover neutral detergent fiber content

[0059] (1) After cutting the white clover to 1-2 cm, place it in a dry and ventilated environment to dry naturally. The air-dried samples were ground with a food grinder to a particle size of 30 mesh.

[0060] (2) Put 1.08 g of the above-mentioned white clover sample and 100 ml of neutral washing liquid into a storage bottle (volume 150 ml); screw on the storage bottle cap, and tighten it properly to maintain internal and external ventilation. Then, put the bottle into the pressure cooker, add water to the neck of the pot (the place where the mouth of the bottle is convex), and put it on the fire. After boiling, adjust to a weak boiling state and keep for 10 minutes to degas. Do not cover the pressure cooker during this process.

[0061] (3) Tighten the cap of the preservation bottle, add water to the neck of the bottle, cover the lid of the pressure cooker and put it on the fire, keep th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com