Method for quantitatively evaluating retained austenite in steel by EBSD (electron back scattering diffraction)

A technology for quantitative evaluation of retained austenite, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems such as low quality of surface scanning, geometric fluctuations destroying the quality of backscattering diffraction patterns, etc., to achieve The effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

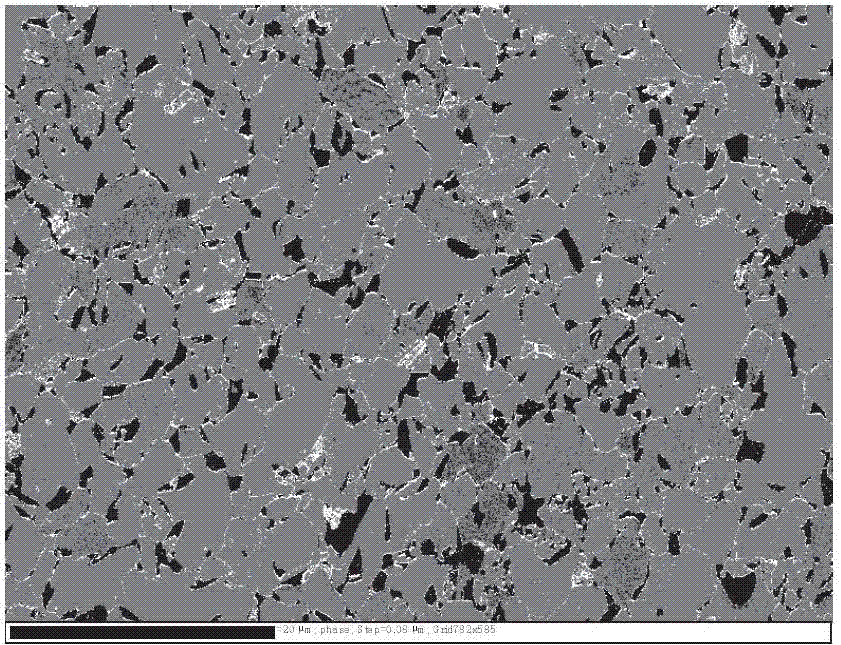

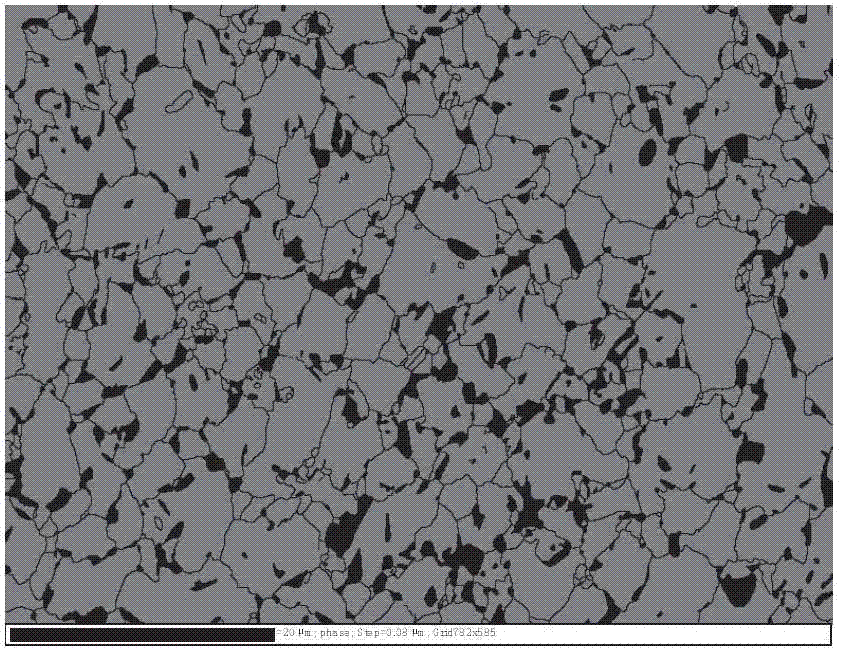

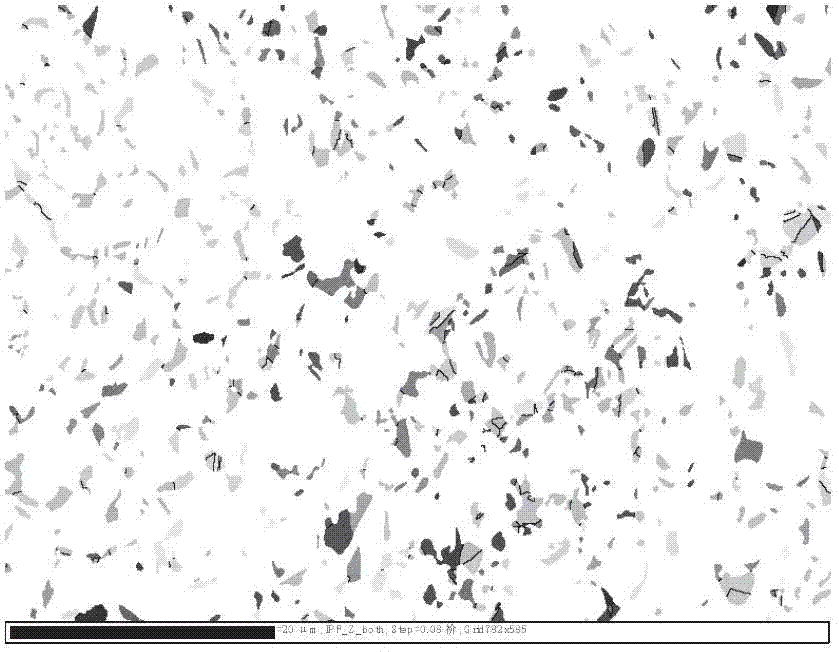

[0026] Morphological distribution of retained austenite grains in TRIP780

[0027] (1) Sampling. A sample of TRIP780 cold-rolled continuous annealed thin steel plate with a thickness of 1mm is taken, and the size is 1×2cm. The surface of the sample was polished with sandpaper to remove the decarburized layer of about 60 μm on the surface. After grinding and mechanical polishing to no scratches, clean with ultrasonic alcohol. Then use electrolytic polishing, select a polishing cover with an area of 1 / 2cm2, set the voltage at 22~23V, use liquid nitrogen to reduce the temperature of the electrolyte to 7~10°C, and control the polishing time at 10~15s. Microstructure can be revealed after electropolishing.

[0028] (2) Set scan parameters. The grain size of ferrite in this sample is about 10 μm, and most of the retained austenite grains are smaller than μm. When the magnification of 2000 times is selected, there are about 300 to 400 ferrite grains in the field of view at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com