Insulating rope sectional withstand voltage test device

A technology of withstand voltage test device and insulating rope, which is applied in the direction of testing dielectric strength, etc., can solve the problems of low work efficiency, cumbersomeness, confusion of insulating rope methods, etc., so as to improve accuracy and flexibility, improve work efficiency, and shorten the test. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

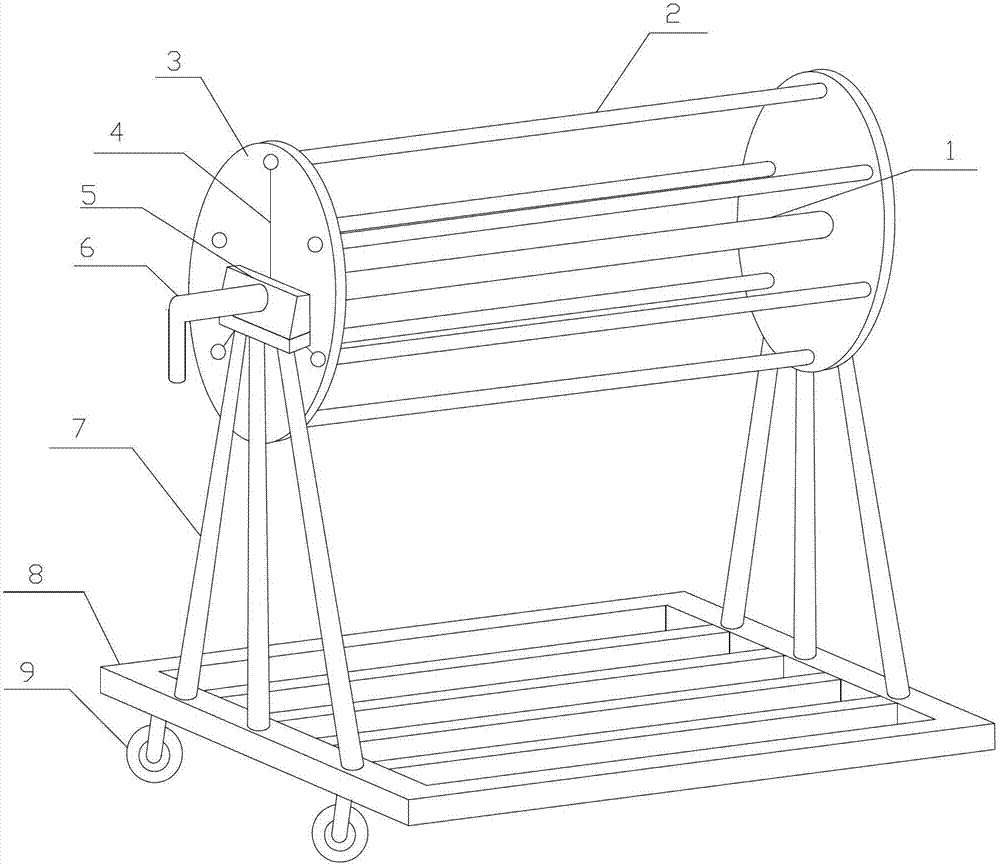

[0012] As shown in the accompanying drawings, the present invention adopts the principle of spinning wheel to be elaborately manufactured, and the insulating end plates 3 on both sides of the upper drum part are made into a circle with insulating plates with good insulating properties, so as to fix the test electrodes 2 and ensure the insulation between the test electrodes 2. effect. The test electrode 2 is made of a stainless steel rod with a diameter of 20mm and a length of 1200mm. One is to make the drum part firm, and the other is to facilitate the winding of the insulating rope. Considering practicality, aesthetics and dexterity, six test electrodes 2 are evenly arranged on the same circumference on the two insulating end plates 3, that is, three are pressurized electrodes, and three are ground electrodes, and they are arranged alternately (that is, two adjacent test electrodes 2 One of them is a pressurized electrode, and the other is a grounding electrode), and the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com