Metal wire filled near-diamond big air hole inner cladding polarized photon crystal fiber

A technology of photonic crystal fiber and large air hole, which is applied in the direction of polarization fiber, cladding fiber, light guide, etc., and can solve the problems of not being able to realize the beam splitting and filtering effect well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

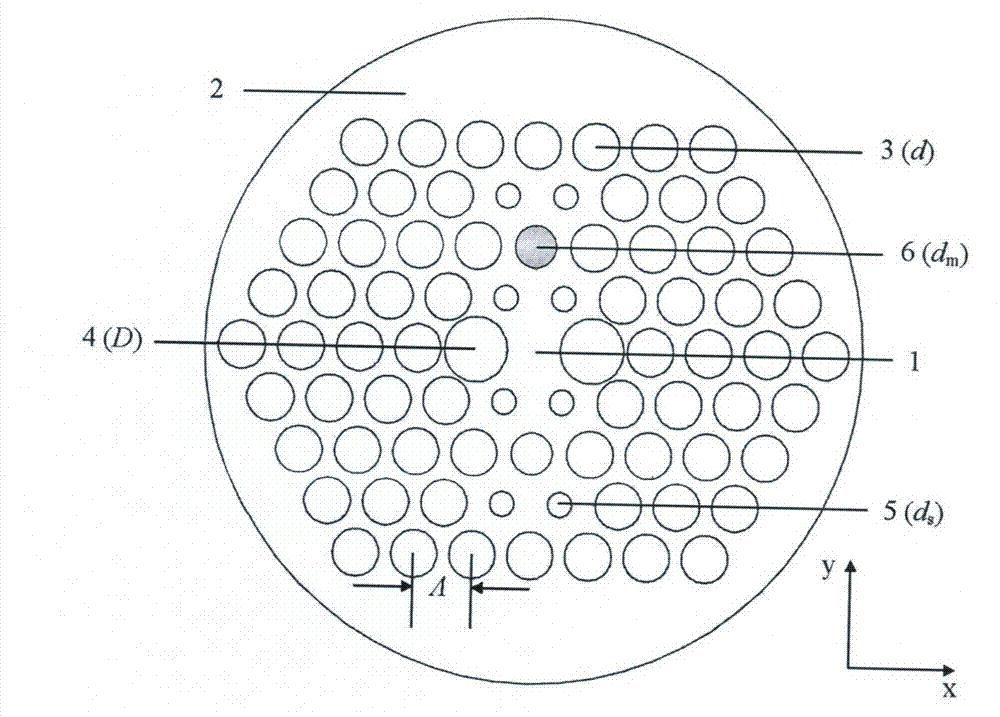

[0015] Such as figure 1 As shown, a metal wire fills the inner cladding polarization photonic crystal fiber with nearly diamond-shaped large air holes, which is composed of a core 1, a background material 2, large air holes 3 and 4 in the cladding, small air holes 5 and filling wire 6 , the background material 2 is a quartz material, and its cladding air holes are evenly distributed on each node of the triangular array. The core area is formed by the absence of the central air hole, and the air holes of different sizes in the two orthogonal polarization directions form the high birefringence region of the fiber: Two larger air holes 4 diameters in the innermost layer along a certain polarization direction (x) D 5 diameters of 2.6 microns, eight small air holes in the innermost and third layers along the polarization direction orthogonal to it (y) d s 1 micron, other air holes 3 diameter d 1.9 microns, the hole spacing between two adjacent air holes Λ 2.4 microns, the air ...

Embodiment 2

[0018] Such as Figure 4 Shown, a kind of metal wire fills the cladding polarized photonic crystal fiber in the nearly diamond-shaped big air hole, and it is by fiber core 1 ', background material 2 ', cladding big air hole 3 ', 4 ', small air hole 5 ' and It is composed of filling wire 6', the background material 2' is quartz material, and the cladding air holes are evenly distributed on each node of the triangular array, the central air hole is absent to form the core area, and the air holes of different sizes in the two orthogonal polarization directions Form the high birefringence region of the fiber: two larger air holes 4' diameter in the innermost layer along a certain polarization direction (x') D′ 2.6 microns, eight small air holes 5' in diameter along the polarization direction orthogonal to it (y') in the innermost and third layers d s ′ to 1 micron. The diameter of other air holes 3' of the optical fiber d′ 1.9 microns, the hole spacing between two adjacent ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com