Hollow cube-corner prism optical delay line device with endogenous scale light source

A corner cube prism and ruler technology, applied in the field of optical instruments, can solve problems such as difficulty in guaranteeing the posture of the right-angle prism and incident light, difficulty in obtaining a delayed signal with stable return light ratio, complicated calibration process, etc., to achieve fast measurement speed and excellent installation process Simple, low-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

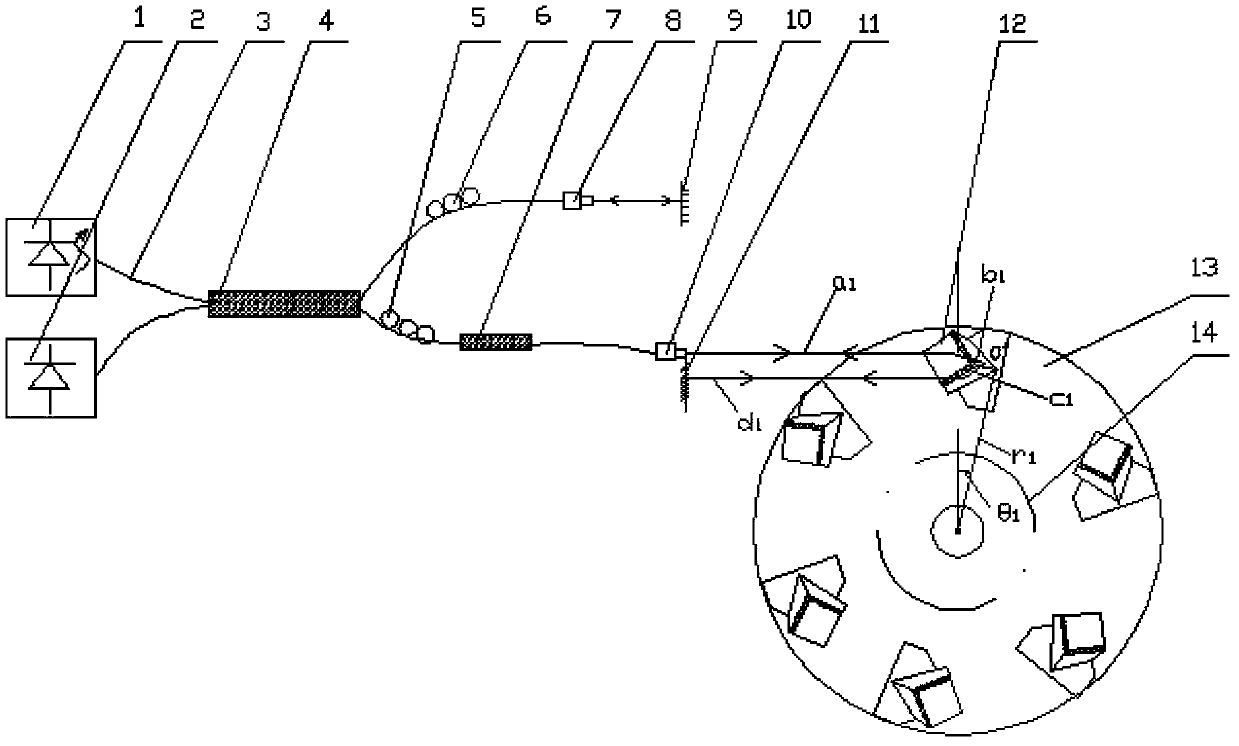

[0032] The light source of the ruler adopts a narrow-line light source, and a DFB (Distributed Feed Back) laser with a wavelength of 1310nm and a bandwidth of 10MHz is selected. Of course, other narrow-line light sources that meet the requirement that the coherence length is greater than the optical path change of the delay line can be selected. The light source of the scale passes through a single-mode fiber And the 2×2 fiber coupler is divided into two optical fibers, the first of which passes through the polarization controller P 1 After adjusting to linear polarized light, it enters the optical collimator Z 1 , becomes collimated light and shoots vertically to the plane reflector FX, and passes through the plane reflector F 1 After reflection, return to the original path, pass through the 2×2 fiber coupler, and enter the photoelectric sensor. The second path passes through the polarization controller P 2 After being adjusted to linear polarization, it enters the waveleng...

example 2

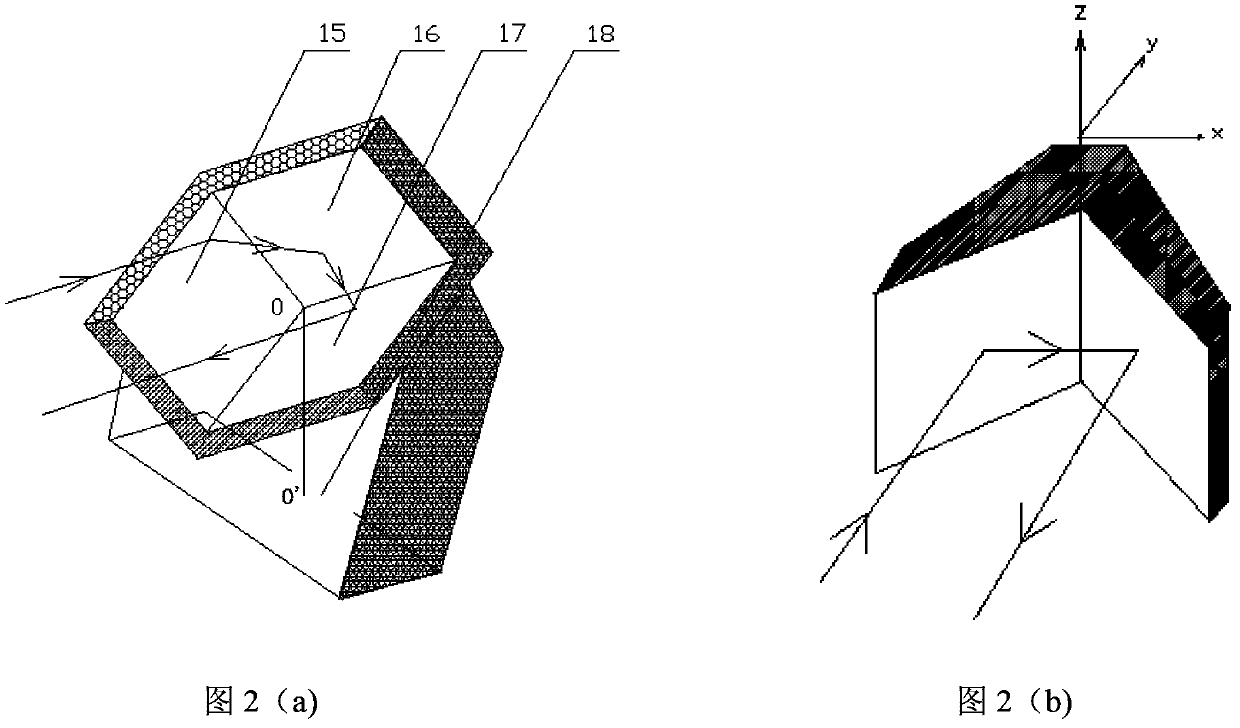

[0040] Compared to hollow corner cubes, such as figure 2 As shown in (b), a simplified example that is easy to think of is a hollow right-angle prism, which is made of two pieces of flat glass or other materials with high-precision working surfaces. Angle of incident light, the rotation of the hollow rectangular prism around the z axis will not affect the coplanar parallel relationship between the outgoing light and the incident light, but the rotation of the hollow rectangular prism around the y axis and the x axis will affect the coplanar relationship between the outgoing light and the incident light face parallel relationship.

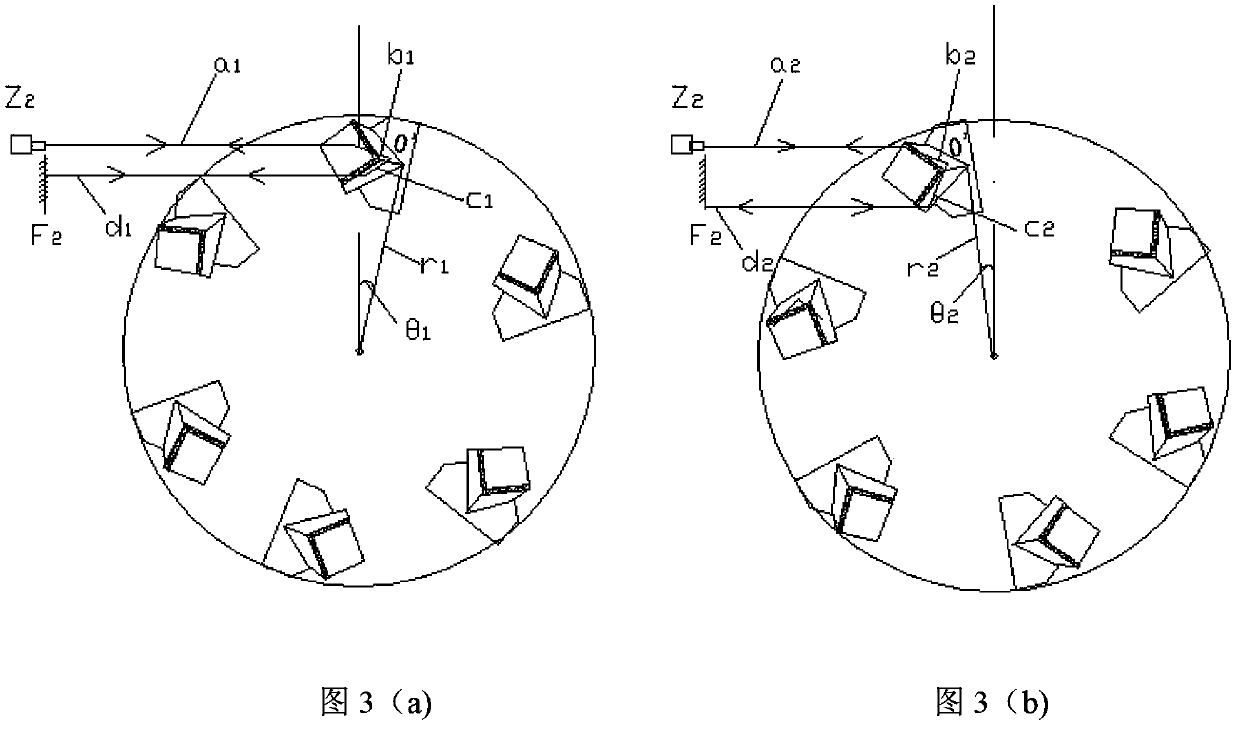

[0041] When using this device, the signal light source passes through the polarization controller P along the single-mode fiber 2 , wavelength division multiplexer, collimator Z 2 Together to the hollow rectangular prism, we can add a fiber coupler to the single-mode optical fiber to expand the number of optical fibers, so as to connect the photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com