Electrochromic device

A technology of electrochromic and electrochromic materials, applied in the direction of color-changing fluorescent materials, circuits, photovoltaic power generation, etc., can solve the problems of easy surface pollution of glass, ineffective heat insulation of glass, and difficult cleaning of high-rise glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

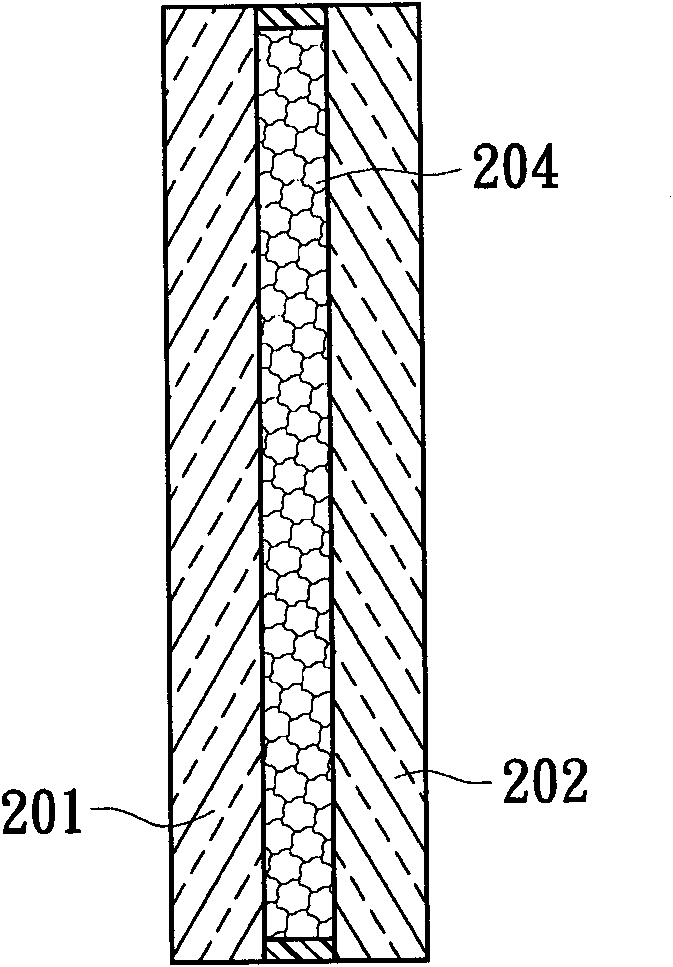

[0090] image 3 A schematic diagram showing one embodiment of the electrochromic device of the present invention.

[0091] image 3 The left side of the center shows a first substrate 301 and a second substrate 302, and an airgel layer 304 is encapsulated therebetween, and a first conductive material layer is formed on the surface of the second substrate 302 opposite to the airgel layer 304 305, such as an indium tin oxide (ITO) material layer coated on the surface of the second substrate 302, and a second conductive material layer 306 is formed on one surface of the third substrate 303, which can also be indium tin oxide (ITO) The material layer corresponds to the structure formed by the second substrate 302 and the first conductive material layer 305 .

[0092] An electrochromic material layer 307 is filled between the first conductive material layer 305 and the second conductive material layer 306, and another voltage source 32 is electrically connected to the first condu...

no. 2 example

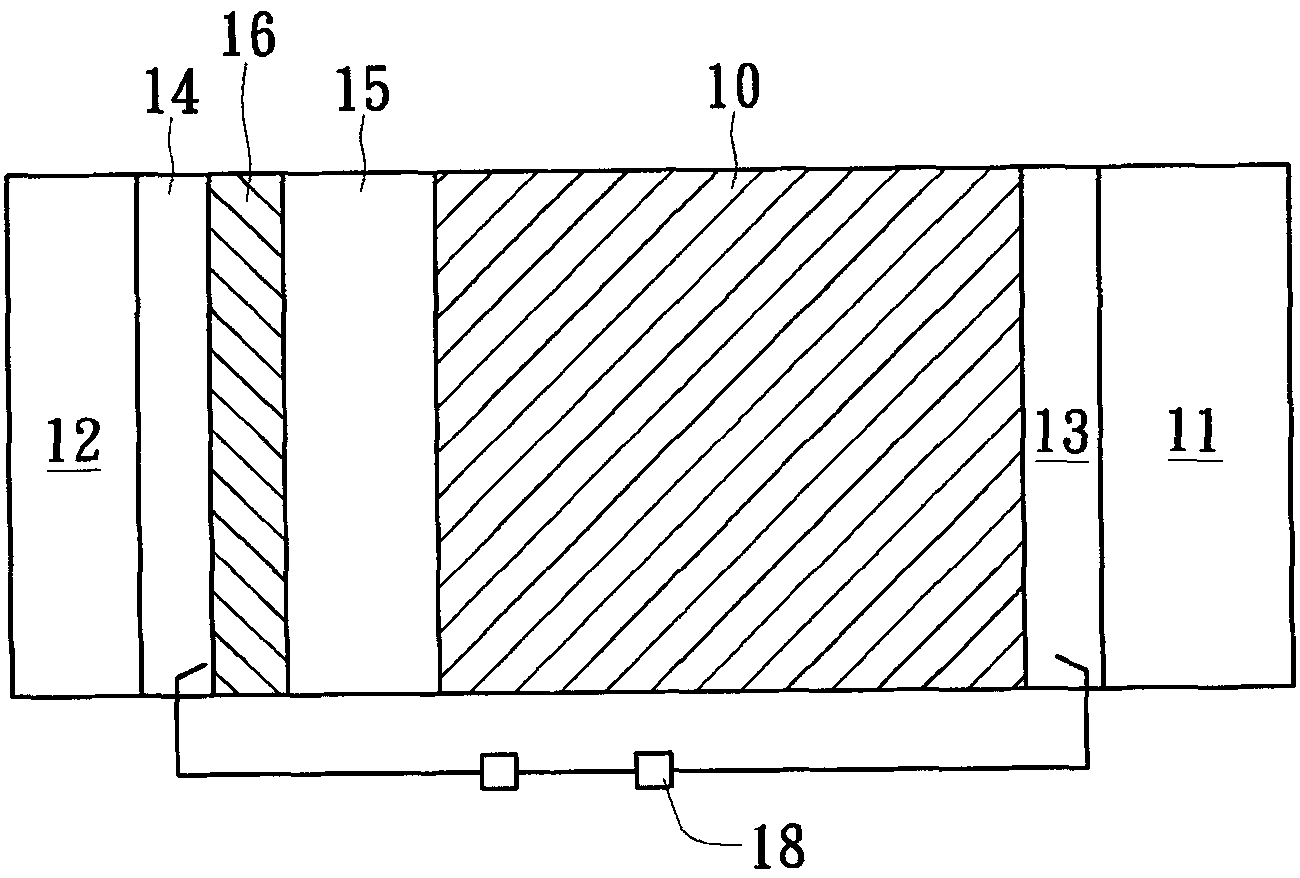

[0095] The above-mentioned voltage source 32 can be provided by the device itself, such as Figure 4 The schematic diagram of the second embodiment of the electrochromic device is shown.

[0096] The figure also includes a first substrate 301, a second substrate 302 and an airgel layer 304 packaged therebetween, and a first conductive material layer 305 formed on the other side surface of the second substrate 302, and the surface of the third substrate 303 A second conductive material layer 306 is formed, and an electrochromic material layer 307 is encapsulated between the first conductive material layer 305 and the second conductive material layer 306 .

[0097] In this example, the first photocatalyst layer 309 used for decontamination and sterilization is coated on the outer surface of the third substrate 303, and a solar power supply layer can be attached on the other surface of the first substrate 301 relative to the airgel layer 304. 312, the solar power layer 312 can g...

no. 3 example

[0102] Figure 6 A schematic diagram showing the third embodiment of the electrochromic device of the present invention.

[0103] The electrochromic device 60 shown in the figure has a first substrate 601 and a second substrate 602, and includes a first conductive material layer 603 and a second conductive material layer 604 respectively formed on the surface thereof, and the structures on both sides are mutually assembled. An electrochromic composite material layer 605 is packaged between the first conductive material layer 603 and the second conductive material layer 604 .

[0104] In one embodiment, the above-mentioned electrochromic composite material layer 605 has special semiconductor characteristics, so it is possible to have abnormal electrical connection problems with adjacent structures (such as the second conductive material layer 604), such as short circuits, so as shown in FIG. In the illustrated embodiment, a gap layer 608 can be added between the electrochromic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com