Novel low-smoke zero-halogen flame-retardant fire-resistant and impact-resistant cable for nuclear power station

A nuclear power plant, flame-retardant technology, applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve problems such as shedding, loss of fire resistance of cables, release of toxic gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

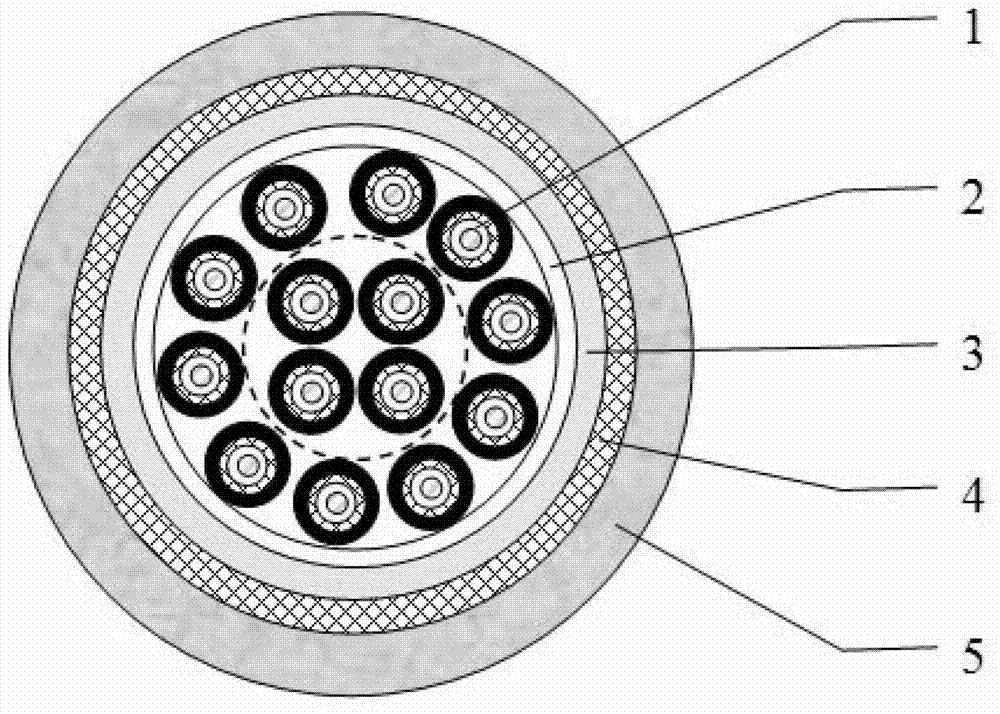

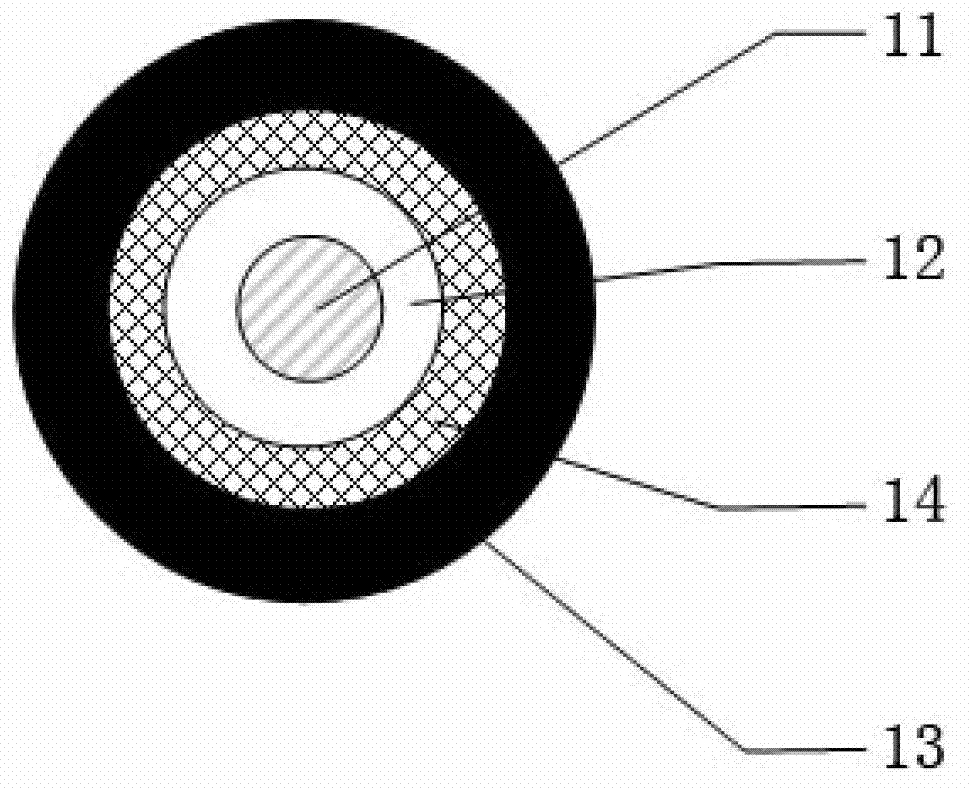

[0030] Reference figure 1 with figure 2 , The new type of low-smoke halogen-free flame-retardant fire-resistant and impact-resistant cable for nuclear power plants of the present invention. A calcined muscovite tape 12 is wrapped around the outer circumference of the tinned copper conductor 11. The outer periphery of the calcined muscovite tape 12 is extruded with an insulating layer 13 from the inside to the outside. The glass fiber yarn layer 14 is fixed on the outer circumference of the calcined muscovite tape in a weaving manner. The tinned copper conductor 11, the calcined muscovite tape 12, the glass fiber yarn layer 14 and the insulating layer 13 constitute the core 1 of the cable of the present invention. The calcined muscovite tape is made of calcined muscovite paper, a single-layer alkali-free glass fiber cloth as reinforcing materials, and is bonded with high temperature resistant organic silica gel. The amount of the calcined muscovite tape is 170-190g / m 2 , The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com