SiGe base vertical channel strain BiCMOS (Bipolar Complementary Metal Oxide Semiconductor) integrated device and manufacturing method

A vertical channel, integrated device technology, used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the increase in device feature size integration and complexity, and do not have the conditions and limitations to replace silicon-based processes Problems such as the development of Si integrated circuit manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

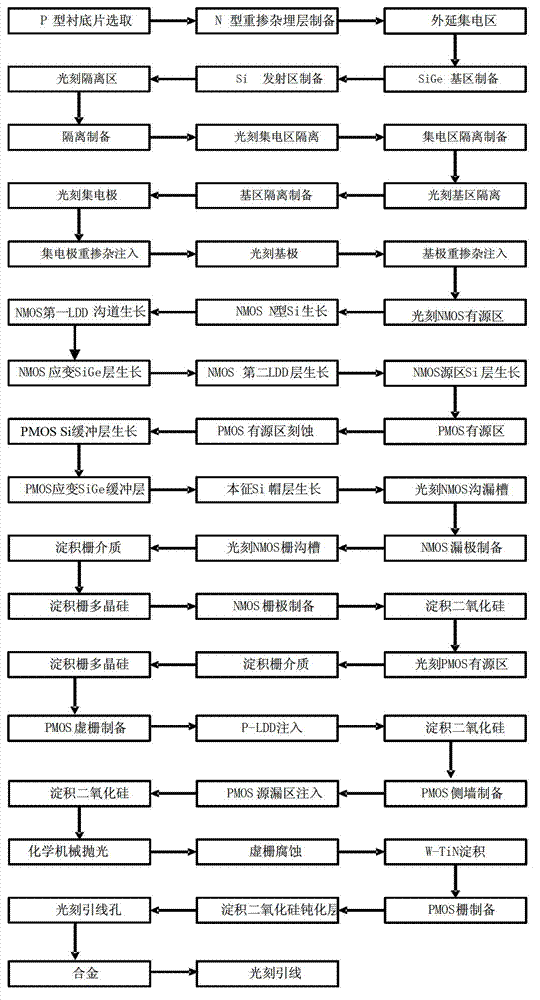

Image

Examples

Embodiment 1

[0133] Embodiment 1: The SiGe-based vertical channel strained BiCMOS integrated device and circuit with a conductive channel of 45nm are prepared, and the specific steps are as follows:

[0134] Step 1, preparation of the buried layer.

[0135] (1a) Select the doping concentration to be 5×10 14 cm -3 A P-type Si sheet as a substrate;

[0136] (1b) Thermally oxidize a layer of SiO with a thickness of 300nm on the substrate surface 2 layer;

[0137] (1c) Photoetching the buried layer region, implanting N-type impurities into the buried layer region, and annealing at 800° C. for 90 minutes to activate the impurities to form an N-type heavily doped buried layer region.

[0138] Step 2, preparing the active region of the bipolar device.

[0139] (2a) An N-type epitaxial Si layer with a thickness of 2 μm is epitaxially grown on the substrate as the collector region, and the doping concentration of this layer is 1×10 16 cm -3 ;

[0140] (2b) Using chemical vapor deposition (C...

Embodiment 2

[0212] Embodiment 2: The conductive channel is prepared as a SiGe-based vertical channel strained BiCMOS integrated device and circuit, and the specific steps are as follows:

[0213] Step 1, preparation of the buried layer.

[0214] (1a) Select the doping concentration to be 1×10 15 cm -3 A P-type Si sheet as a substrate;

[0215] (1b) Thermally oxidize a layer of SiO with a thickness of 400nm on the substrate surface 2 layer;

[0216] (1c) Photoetching the buried layer region, implanting N-type impurities into the buried layer region, and annealing at 900° C. for 60 minutes to activate the impurities to form an N-type heavily doped buried layer region.

[0217] Step 2, preparing the active region of the bipolar device.

[0218] (2a) An N-type epitaxial Si layer with a thickness of 2.5 μm is epitaxially grown on the substrate as a collector region, and the doping concentration of this layer is 5×10 16 cm -3 ;

[0219] (2d) Using chemical vapor deposition (CVD), grow a l...

Embodiment 3

[0291] Embodiment 3: The SiGe-based vertical channel strained BiCMOS integrated device and circuit with a conductive channel of 22nm are prepared, and the specific steps are as follows:

[0292] Step 1, preparation of the buried layer.

[0293] (1a) Select the doping concentration to be 5×10 15 cm -3 A P-type Si sheet as a substrate;

[0294] (1b) Thermally oxidize a layer of SiO with a thickness of 500nm on the surface of the substrate 2 layer;

[0295] (1c) Photoetching the buried layer region, implanting N-type impurities into the buried layer region, and annealing at 950° C. for 30 minutes to activate the impurities to form an N-type heavily doped buried layer region.

[0296] Step 2, preparing the active region of the bipolar device.

[0297] (2a) An N-type epitaxial Si layer with a thickness of 3 μm is epitaxially grown on the substrate as the collector region, and the doping concentration of this layer is 1×10 17 cm -3 ;

[0298] (2d) Using chemical vapor deposi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com