Automatic loading and unloading device of lithium battery pole piece

An automatic loading and unloading, lithium battery technology, applied in the direction of secondary batteries, secondary battery manufacturing, circuits, etc., can solve the problems of high labor intensity and low work efficiency of workers, achieve simple structure, convenient operation, and avoid repeated film penetration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

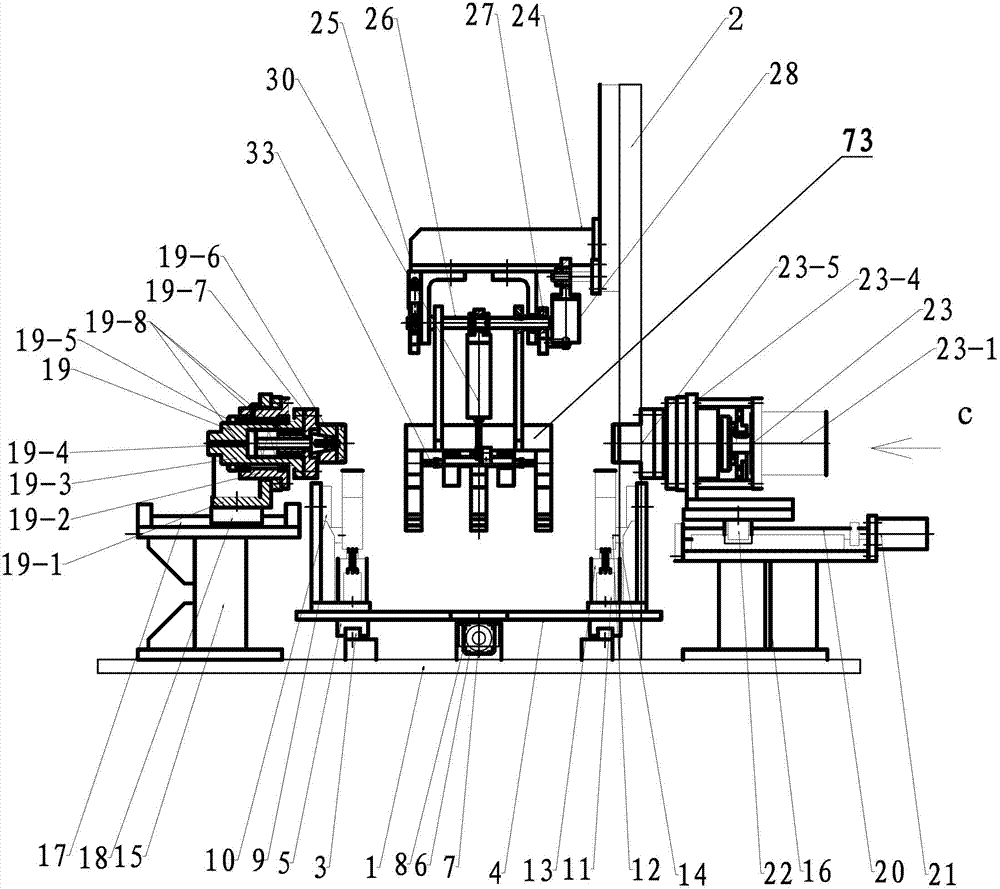

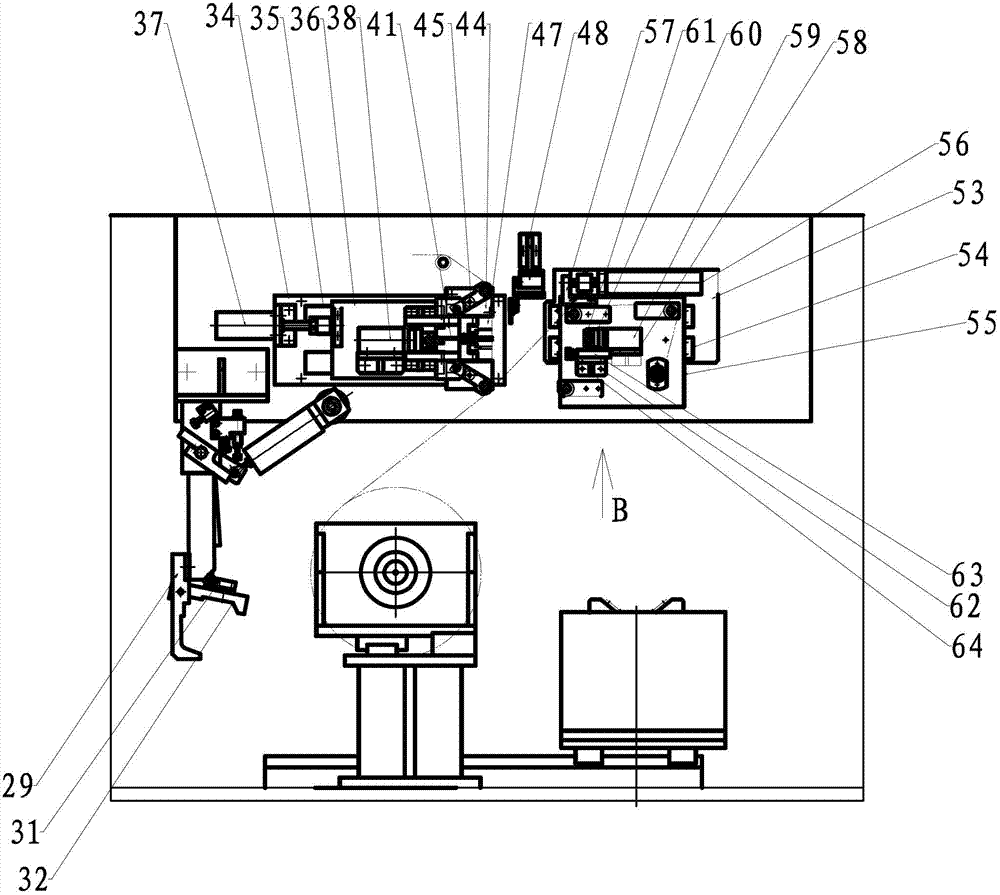

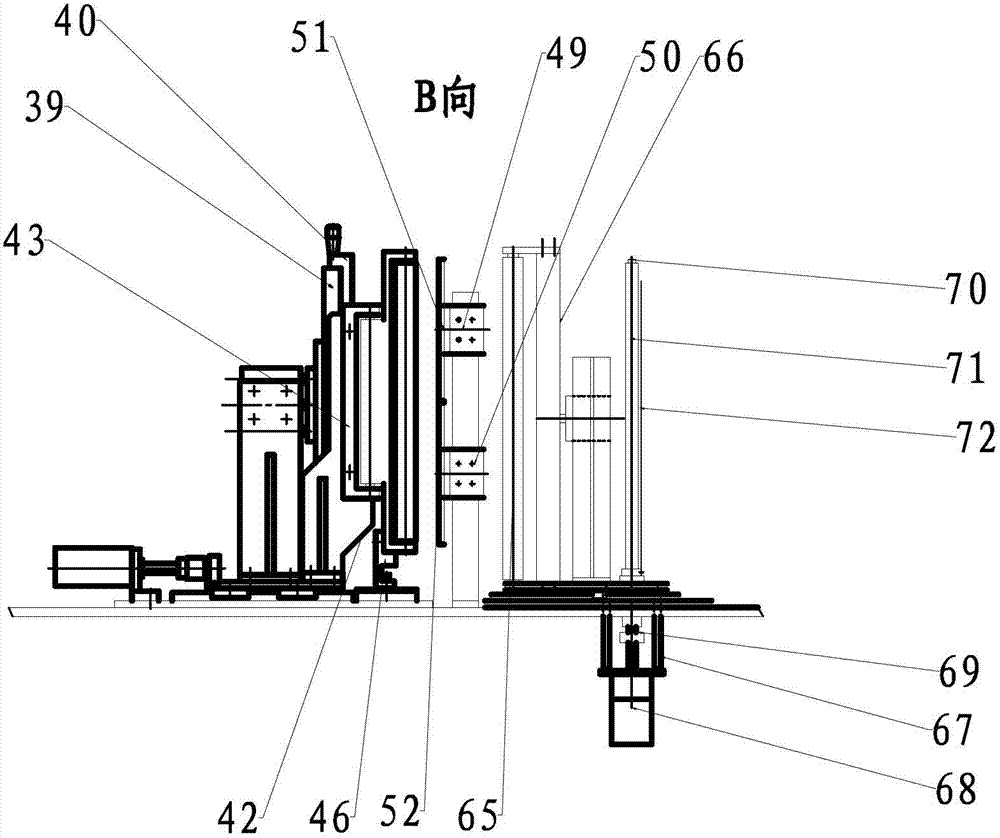

[0021] Such as Figure 1~4 As shown, the present invention mainly includes a horizontal plate 1, a vertical plate 2, a first transport line rail 3, a support plate 4, a first slider 5, a transport motor 6, a transport screw 7, a nut 8, a line rail plate 9, a second Carrying line rail 10, support seat 11, support 12, carrying cylinder 13, carrying slider 14, left unwinding support 15, right unwinding support 16, rodless cylinder 17, sliding piston 18, left unwinding mechanism 19, wire Rod 20, first driving motor 21, unwinding nut 22, right unwinding mechanism 23, unloading bracket 24, unloading bracket lower plate 25, fixed jaw 29, movable jaw 32, second unloading shaft 33, slice Base plate 34, slicing line rail 35, first sliding base plate 36, first slicing cylinder 37, second slicing cylinder 38, slide seat 39, knife seat 40, cutter 41, push cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com