Water-cooling and wind-cooling impact crusher set

A pulverizer and cold air technology, applied in grain processing, etc., can solve problems such as inability to adjust equipment functions, inability to directly produce finished products, direct connection of motors to rotors, etc., and achieve the effects of improving process effects, improving crushing efficiency, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

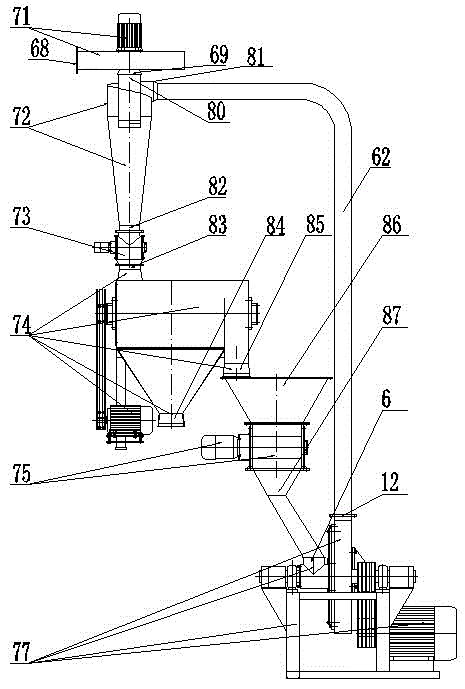

[0024] Such as figure 1 As shown, the water-cooled air-cooled impact pulverizer unit of the present invention includes a pulverizer 77, a feeding device, a centrifugal separator 72 and a grading screen. The feeding device is composed of three parts connected sequentially from top to bottom, and the three parts are successively from top to bottom a feed device feed hopper 86 with a pyramid-shaped lower part, a discharge control device 75 and a feed device discharge pipe 87; the unloading control device 75 is a speed-adjustable unloading valve or a screw conveyor. The pulverizer feed pipe 6 is connected with the feeding device discharge pipe 87 above it, and the grading sieve 74 is provided with a grading sieve feed inlet 83, a finished product outlet 84 and a work-in-progress outlet 85, and the finished product outlet 84 discharges the finished product. The centrifugal separator is provided with an inlet pipe 81 , an air outlet pipe 80 and a discharge pipe 82 . Pulverizer out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com