Electro-pneumatic type automatic pressing machine

An electro-pneumatic and press technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing energy consumption, uneven extrusion transmission, etc., to solve the problem of unstable transmission, improve mechanical transmission efficiency, The effect of saving energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

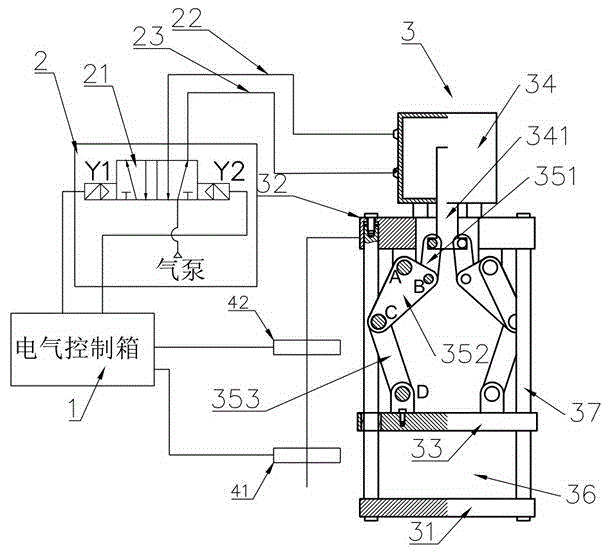

[0013] The present invention aims at the shortage of extrusion molding equipment in the prior art, and designs and proposes an electro-pneumatic automatic press. combine figure 1 Seen similar to conventional equipment, it has an electrical control box 1, an air pump 2 connected to the output of the electrical control box, and a pressure device 3 connected to the output of the air pump. The pressure device 3 is provided with a top plate 32 and a bottom plate 31 with a fixed distance, a middle plate 33 with a variable distance relative to the bottom plate, a cylinder 34 connected to the middle plate and its jacking mechanism, and a workpiece pressing chamber is formed between the middle plate 33 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com