Device and method for machining large-area plane optical element

A technology of optical parts and processing devices, which is applied in the field of large-area planar optical parts processing devices, can solve the problems of low efficiency and high cost, and achieve the effects of reducing costs, reducing electrode temperature, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

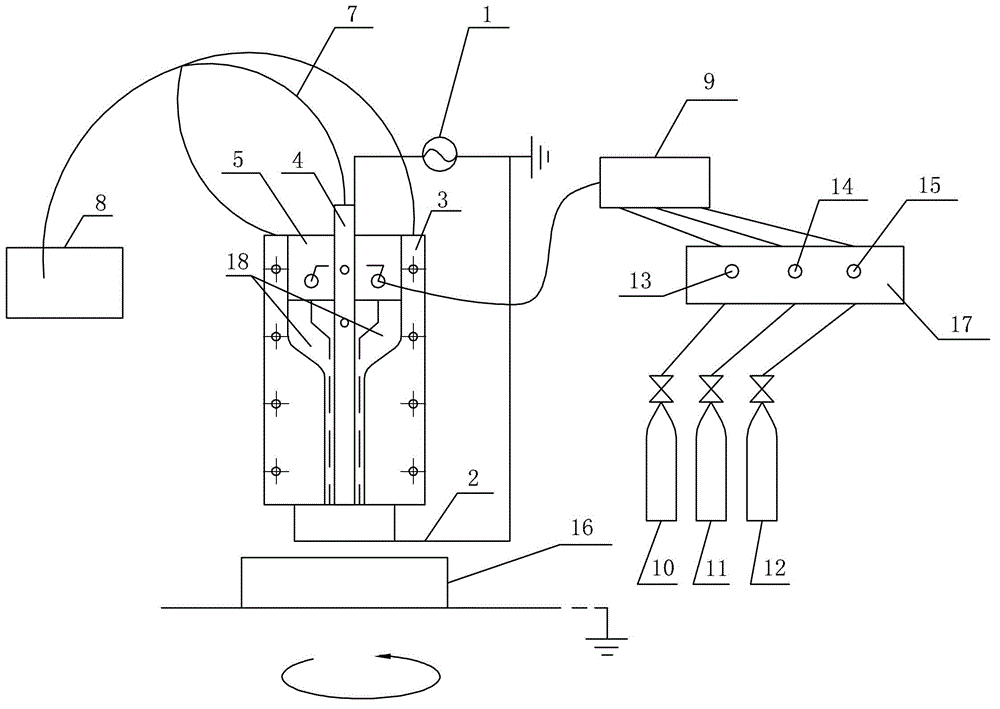

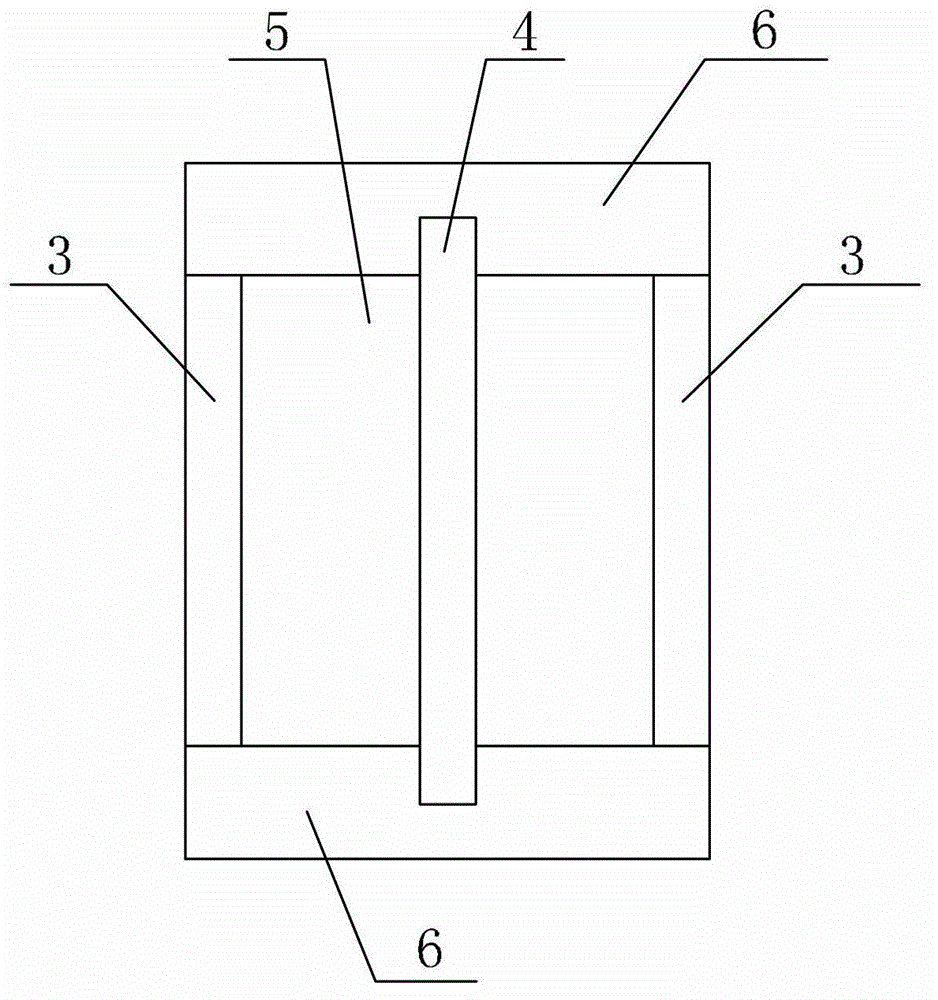

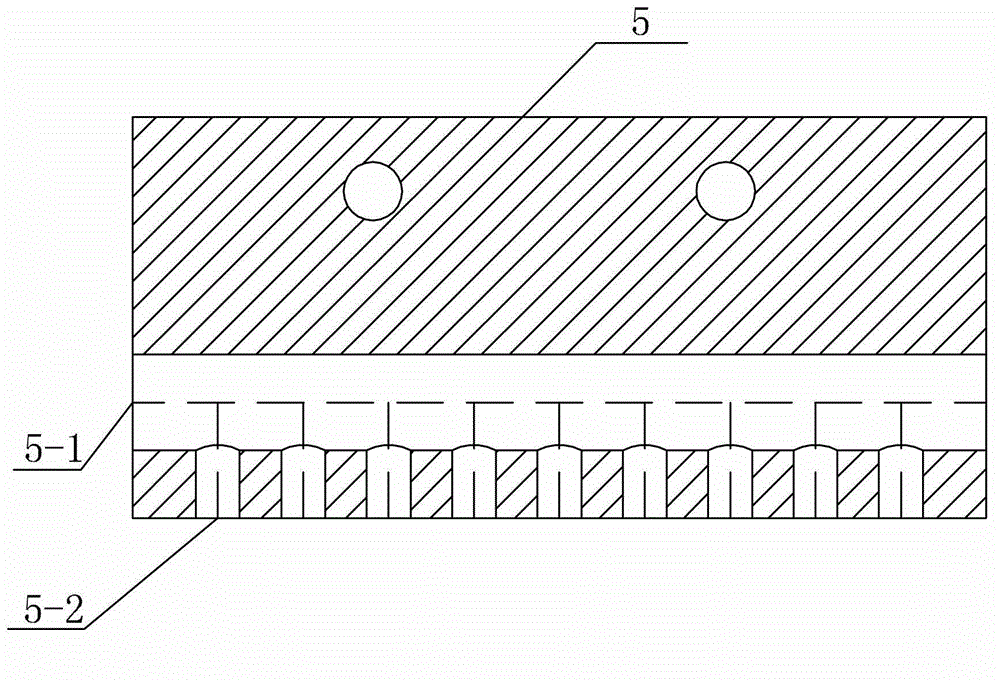

[0023] Specific implementation mode one: as Figure 1-5 As shown, the large-area planar optical part processing device of this embodiment includes a radio frequency power supply 1, a ground wire 2, an inner electrode 4, a deflector 5, a cooling pipe 7, a water tank 8, a flow controller 17, a helium cylinder 10, four Fluorocarbon bottle 11, oxygen bottle 12, two outer electrodes 3 and two isolation plates 6, the radio frequency power supply 1, ground wire 2, inner electrode 4, two outer electrodes 3 and two isolation plates 6 constitute plasma Flat plate discharge structure, the two external electrodes 3 are arranged symmetrically, and the two external electrodes 3 are opposite to the two isolation plates 6 to form a closed structure. The guide plate 5 is arranged on the upper part of the two external electrodes 3 Between the electrodes 3, the lower end of the inner electrode 4 passes through the deflector 5 and the inner electrode 4 is located between the two outer electrodes ...

specific Embodiment approach 2

[0025] Specific implementation mode two: as Figure 4 As shown, the first cooling passage 4-1 in this embodiment is U-shaped. With such a design, the temperature of the internal electrodes can be reduced. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: as figure 1 As shown, the processing device in this embodiment further includes an air mixing valve 9, and the flow controller 17 communicates with the two first through holes 5-1 through the air mixing valve 9. With such a design, the gas in the flow controller 17 can be fully mixed. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com