Structured surface contacted with printed material and having substrate and at least one layer

A substrate, structuring technology, applied in the direction of the jacket of the printing press roll, the general parts of the printing machine, the coating, etc., can solve the problem of no description, no substrate roughness measurement value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

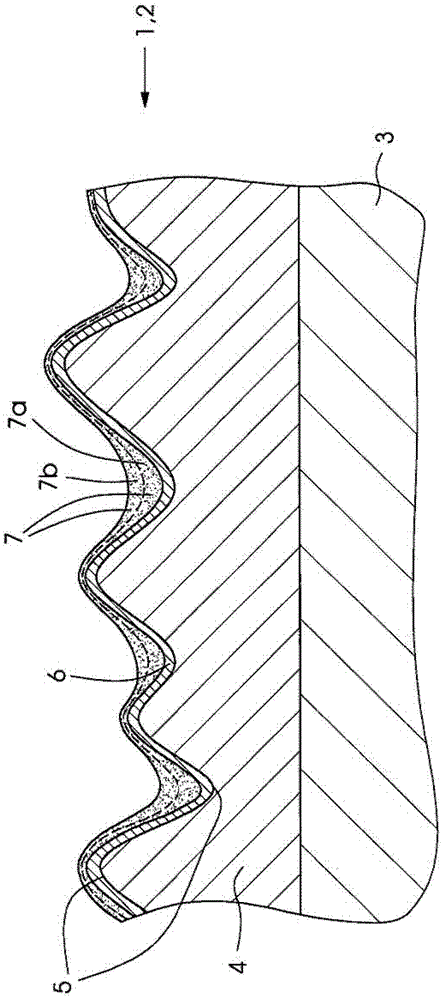

[0026] figure 1 A schematic sectional view of a preferred embodiment of the face 1 of the invention is shown. The surface is designed as a flexible cylinder liner 2 and is held, for example stretched as a so-called sleeve, on a transport cylinder 3 of a printing material processing machine, for example an offset printing press for processing sheets.

[0027] The surface 1 comprises a base 4 made of nickel. The base body has structures 5 (peaks and valleys) produced by galvanic molding (electroforming). The nickel substrate is chrome-plated, that is to say provided with a chrome layer 6 .

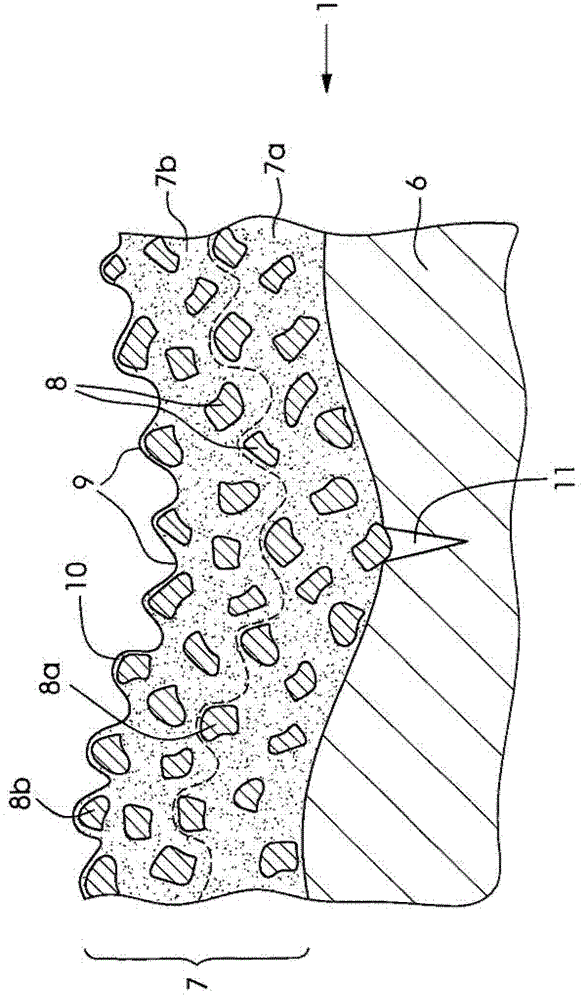

[0028] A sol-gel layer 7 is arranged on the chrome layer 6 . The sol-gel layer has a lower layer 7a and an upper layer 7b composed of sol-gel. Particles 8 composed of cobalt-aluminate are embedded in the two layers (cf. figure 2 ).

[0029] exist figure 1 As can be seen in , the two layers 7a and 7b flatten the coarse structure 5 somewhat. The two layers 7a and 7b are slightly thinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap