Wire cutting and winding device

The technology of a winding device and a wire pay-off device is applied in the field of wire cutting and winding devices, which can solve the problems of high labor intensity, difficult operation, and large floor space, so as to achieve automatic production, reduce labor intensity, and reduce floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

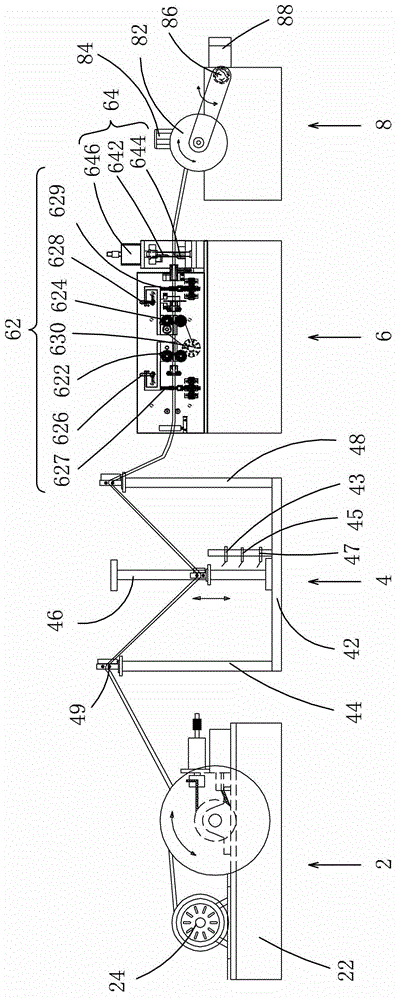

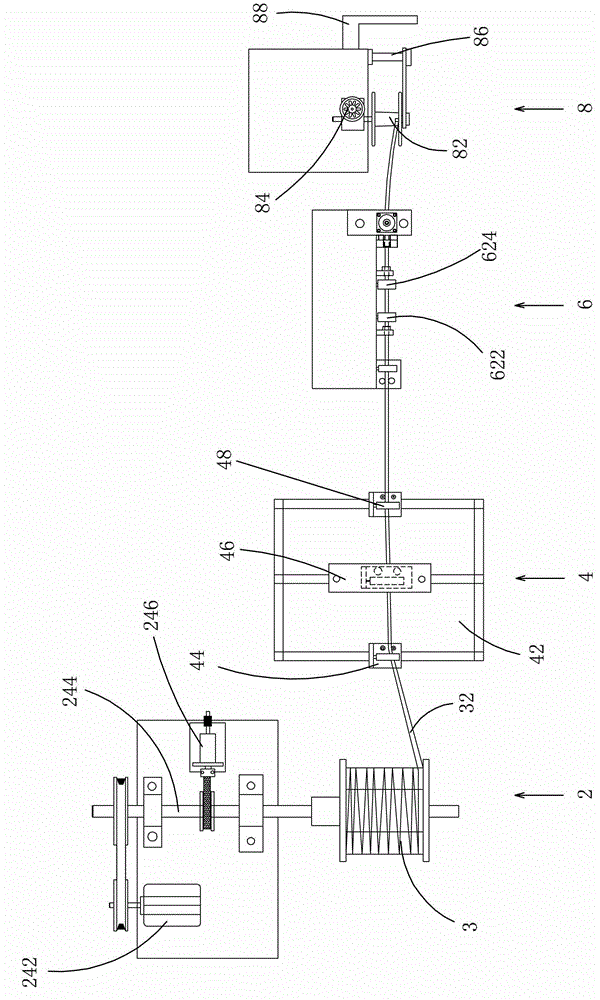

[0023] See figure 1 and figure 2 , The present invention provides a wire cutting and winding device, comprising: a wire pay-off device 2, a wire storage device 4, a counting and cutting device 6 and a wire winding device 8. The wire pay-off device 2 is used to place the wire reel 3, the wire reel The cable 32 on 3 enters the counting and cutting device 6 through the storage device 4, and is counted by the counting and cutting device 6 and then wound on the winding device 8. The counting and cutting device 6 performs Counting, when the length of the passing cable 32 reaches a preset length, the counting and cutting device 6 cuts the cable 32.

[0024] The wire pay-off device 2 includes a frame body 22 and a transmission device 24 arranged on the frame body 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com