Continuously-operated activated carbon adsorption tower

A technology of activated carbon adsorption tower and connecting rod, which is applied in the direction of adsorption water/sewage treatment, etc., which can solve the problems of waste of resources, high operating cost, and high investment at one time, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

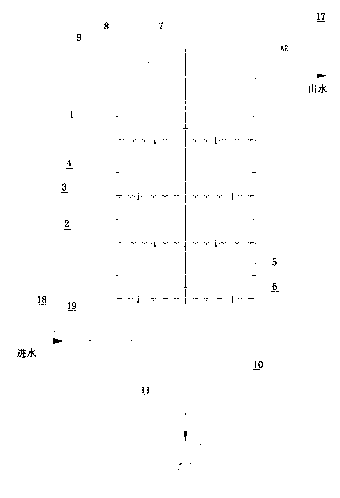

[0017] see figure 1 , which is a continuous operation activated carbon adsorption tower of the present invention. As shown in the figure: it consists of a cylinder body 1 with a water inlet and a sampling port, a discharge hopper 10, two or more porous plates 2 fixed in the cylinder body 1, a water outlet device 8, and a water collection tank 9; the water inlet Located below the lowermost perforated plate, the water outlet device 8 and the water collection tank 9 are located above the cylinder body 1; the bottom of the discharge hopper 10 is provided with a discharge port, and a discharge valve 11 is installed at the discharge port; The special filter water cap 3 is evenly installed on the porous plate 2 described above, and its gap must be smaller than the filter material particles; each porous plate 2 is also equipped with a lifting switch 5 corresponding to the hole on the porous plate, and each porous plate The lifting switch 5 of the plate is respectively fixed on the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com