A kind of manufacturing method of feedwater sludge composite filler and its filler bed

A composite filler and water supply sludge technology, which is applied in water/sludge/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. large problems, to achieve the effect of low cost, good phosphorus removal effect, and high phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the invention more clearly.

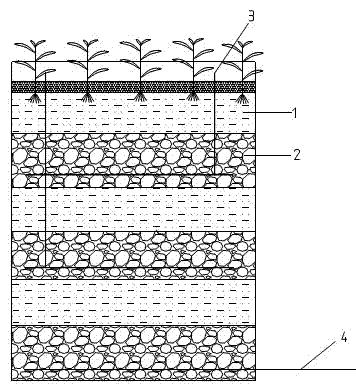

[0017] The components of the water supply sludge composite filler of the present invention include: sludge, anthracite, starch, polyaluminum chloride, and sponge iron. Feedwater sludge is chemically modified and thermally modified to become granular, which has good phosphorus removal effect.

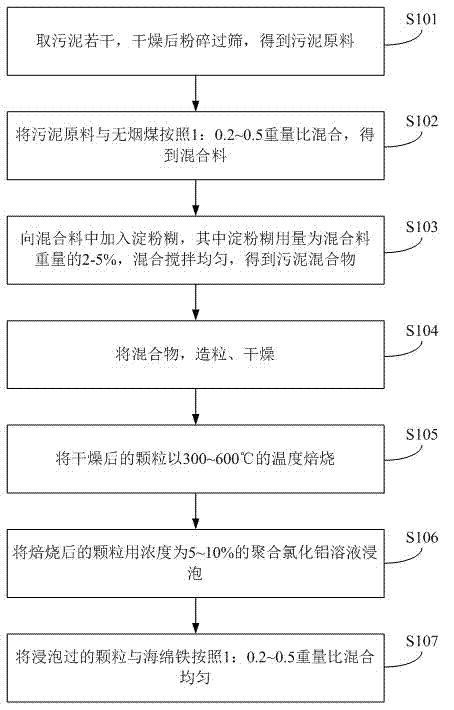

[0018] Concrete preparation process is as follows:

[0019] S101: Take some sludge. The sludge is preferably sludge from the sedimentation tank of the waterworks. The sludge from the sedimentation tank of the waterworks itself has a certain decontamination ability, and the acquisition cost is low. The sludge is naturally dried, and after drying, it is pulverized by a pulverizer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com