Device and method for advancement treatment of printing and dyeing wastewater

A water treatment device, a technology for printing and dyeing wastewater, applied in the textile industry wastewater treatment, water/sewage multi-stage treatment, adsorbed water/sewage treatment, etc. and other problems, to achieve the effect of easy operation, improved removal rate, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

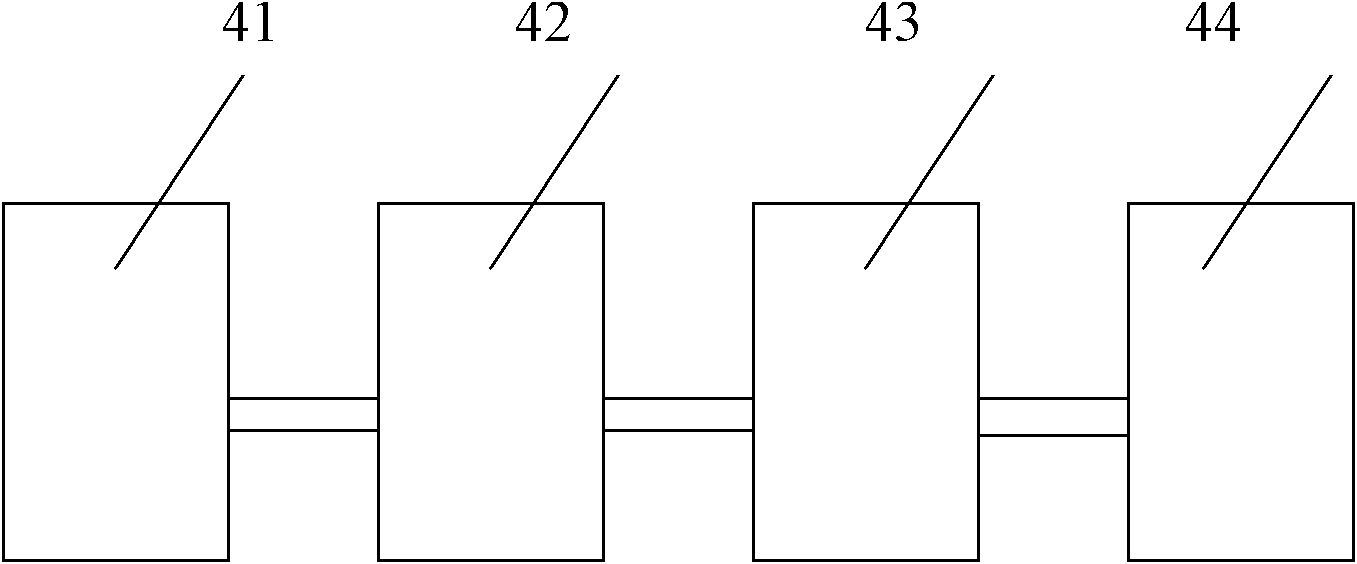

[0038] Such as figure 1 As shown, a printing and dyeing wastewater advanced treatment device of the present invention includes a biological activated carbon water treatment device 41, and the biological activated carbon water treatment device 41 is connected to a biochemical sedimentation tank 42, and the biochemical sedimentation tank 42 is connected to a reverse mineral sand The filter tank 43 is connected, and the reverse mineral sand filter tank 43 is connected with a clear water tank 44.

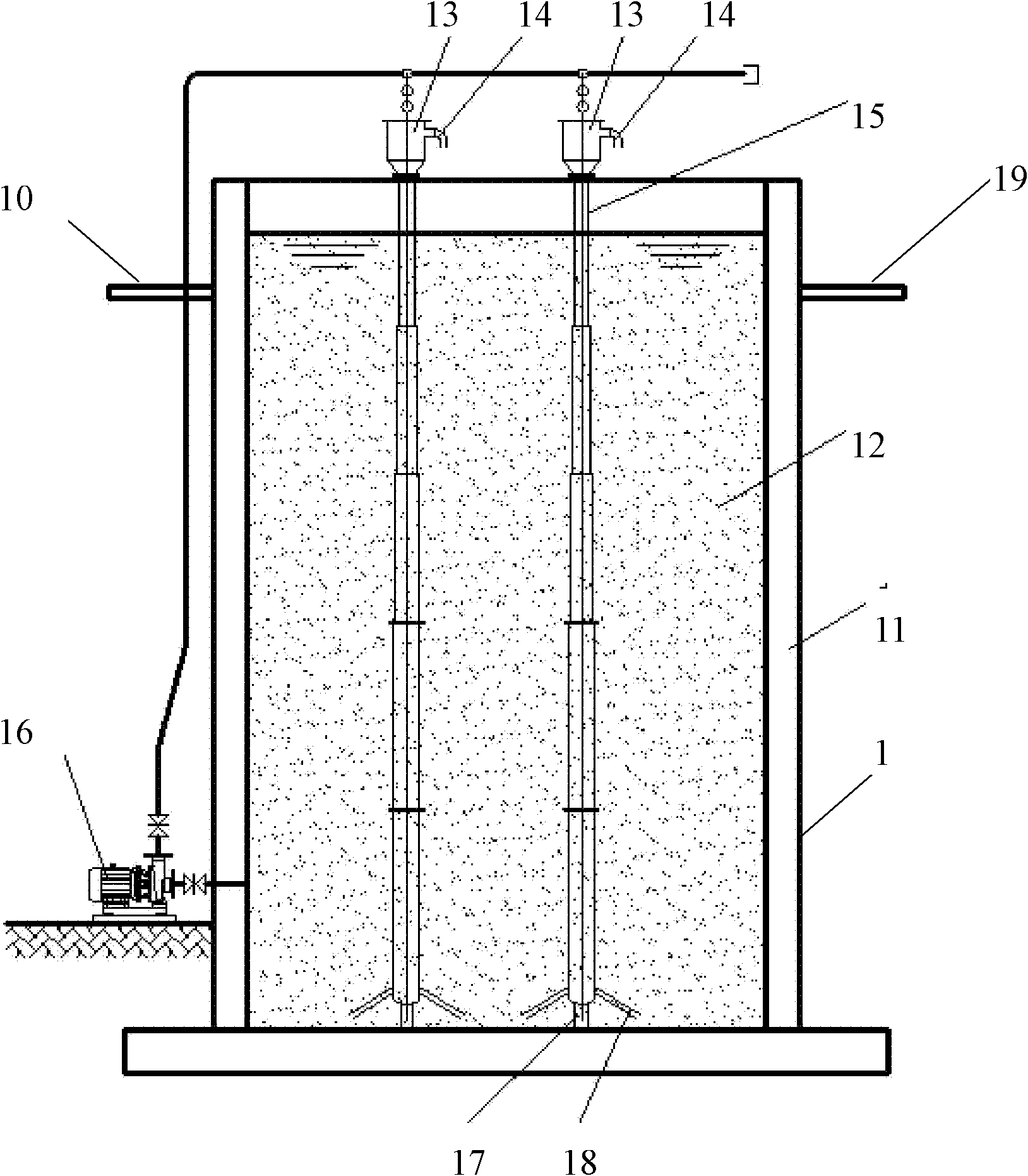

[0039] Such as figure 2 As shown, further, the biological activated carbon water treatment device 41 includes the first treatment tank 1, and also includes at least one biochemical aeration unit, and the biochemical aeration unit includes a negative pressure chamber 13, an air-water diffusion pipe 15 1. A self-suction pipe 14, the air-water diffusion pipe 15 is a straight pipe with openings at both ends, its pipe body is vertical, its pipe diameter expands from top to bottom, and its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com