Stelmor controlled cooling method for 55SiCrA spring steel wire rod

A spring steel and wire rod technology, which is applied in the field of steel rolling, can solve the problems of brittle fracture, coarse grain, affecting the structure uniformity and fatigue performance of oil quenching-tempering springs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

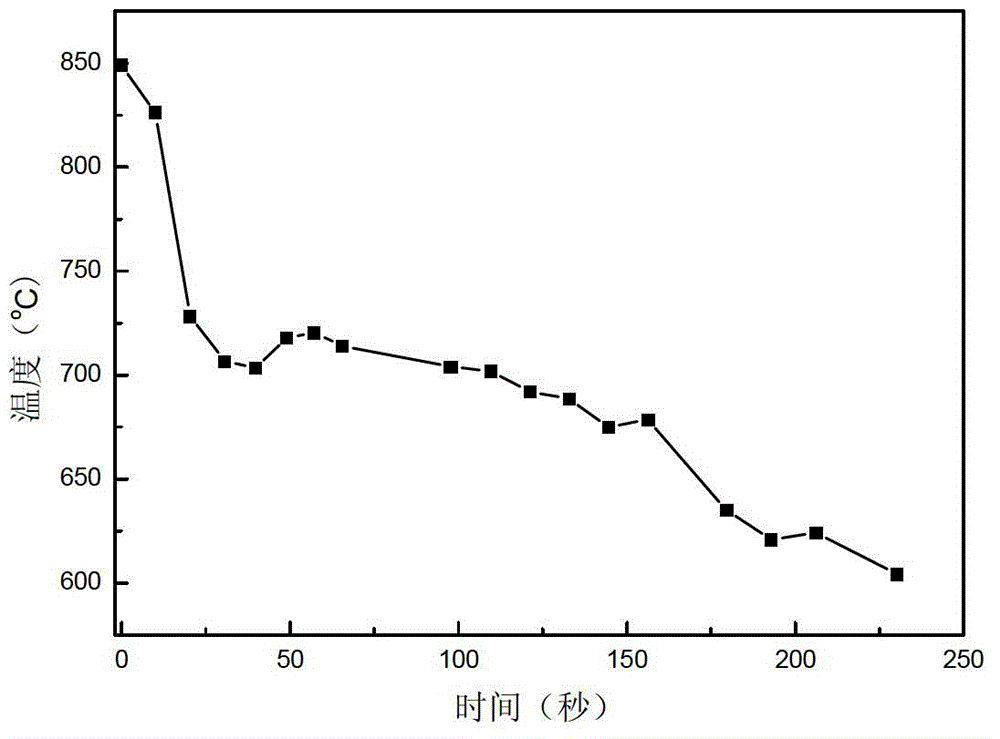

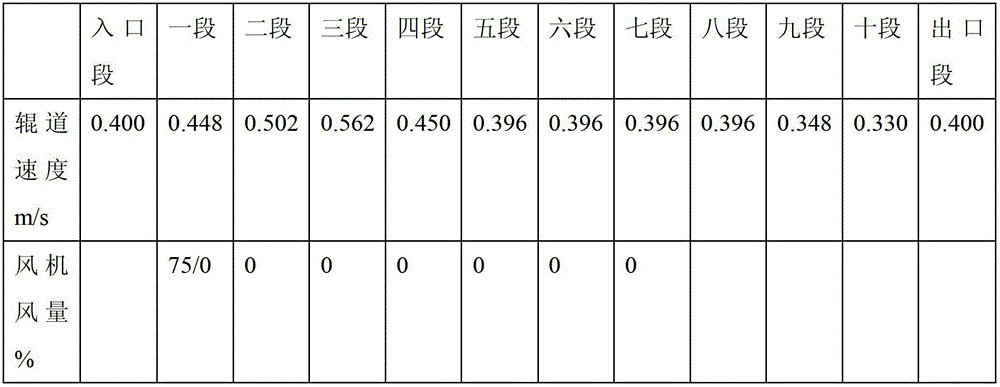

[0017] A Steyrmore controlled cooling method for 13mm55SiCrA spring steel wire rod, the spinning temperature is 849℃; the roller table speed and fan air volume are shown in Table 1, the roller table speed at the entrance section is 0.4m / s, the first fan The air volume is 75%, and the rest are closed; the heat preservation covers on the initial section of 0-30 meters are all opened, and the heat preservation covers are opened every 30 meters on the section of 30-100 meters, and the rest are closed. The measured cooling curve is as figure 1 As shown, the temperature measurement location is the edge of Steyrmo and the dense part of the wire rod. by figure 1 It can be seen that in the initial section of 0-25 meters in Steyrmo ( figure 1 In 0~50s), quickly cool to 706℃ at a cooling rate of 6K / s; on the 25~100m section of Steyrmo, cool slowly at a cooling rate of 0~2K / s, the temperature of the coil is 604 ℃.

[0018] The 13mm55SiCrA wire rod product produced according to the above pro...

Embodiment 2

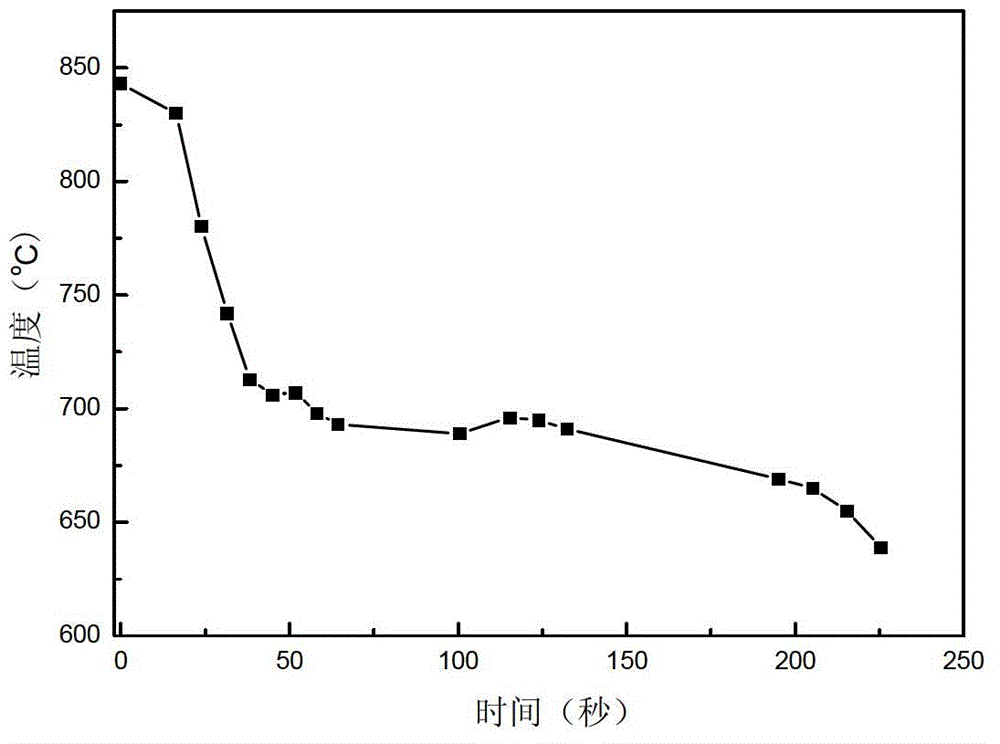

[0022] A Steyrmore controlled cooling method of 10mm55SiCrA spring steel wire rod, the spinning temperature is 843℃; the roller table speed and fan air volume are shown in Table 2, the roller table speed at the entrance section is 0.4m / s, the first fan The air volume is 30%, and the rest are closed; all the insulation covers on the initial section of 0-30 meters in Steyrmo are opened, and the insulation covers are opened every 30 meters on the section of 30-100 meters, and the rest are closed. The measured cooling curve is as figure 2 As shown, the temperature measurement location is the edge of Steyrmo and the dense part of the wire rod. by figure 2 It can be seen that in the initial section of 0-25 meters in Steyrmo ( figure 2 In 0~50s), quickly cool to 705℃ at a cooling rate of 4.8K / s, and slowly cool at a cooling rate of 0~2K / s on the 25~100m section of Steyrmo. The temperature of the coil is 604°C.

[0023] The 10mm55SiCrA wire rod product produced according to the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com