Method for improving coercive force of sintered rare earth-iron-boron permanent magnetic material

A permanent magnet material and coercive force technology, applied in the direction of magnetic material, inorganic material magnetism, metal material coating process, etc., can solve the problem that the magnet is difficult to obtain the diffusion effect, achieve good application prospects, reduce the reduction of remanence, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In this embodiment, the molecular formula representing the composition and mass percentage of the sintered rare earth-iron-boron permanent magnet material is Nd 30 Fe 69 B 1 . The preparation method of the sintered rare earth-iron-boron permanent magnet material is as follows.

[0023] Alloy composition into Nd by quick-setting flake technology 30 Fe 69 B 1 (mass percentage content) of the main alloy is made into quick-setting flakes, and then it is made into a powder with an average particle size of 3.0 microns by hydrogen crushing and jet milling processes. The powder was subjected to secondary orientation pressing in a 2 T magnetic field, and cold isostatic pressing at a pressure of 300 MPa for 60 seconds. The compact was then placed in a vacuum furnace and sintered at 1040 °C for 2 hours. Finally, the sintered permanent magnet material was processed into a size of Φ10mm×10mm to obtain a test sample.

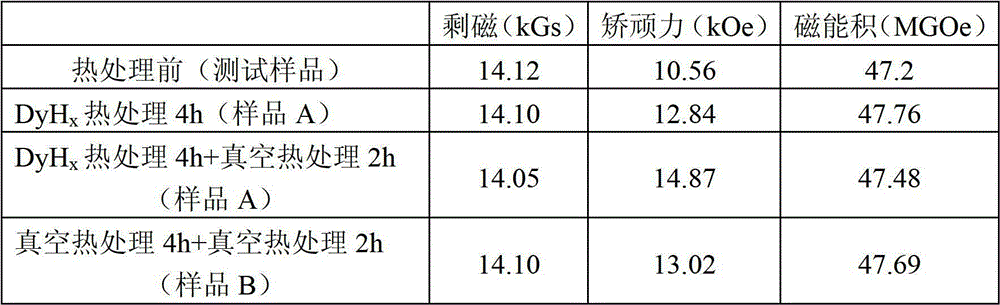

[0024] The test sample was tested for performance, and it...

Embodiment 2

[0035] In this example, the test sample prepared in Example 1 is used.

[0036] A group of samples, Sample C, was taken out of the above test samples and subjected to heat treatment.

[0037] The heat treatment process of sample C is as follows: sample C is buried in the same DyH as in Example 1 x In the powder, heat treatment in vacuum at 800°C for 4 hours, and test its properties after heat treatment, as shown in the table below.

[0038] Then, sample C was placed in a sintering furnace, and subjected to vacuum heat treatment at 500° C. for 2 hours, and the properties of sample C were tested after heat treatment, as shown in Table 2 below.

[0039] Table 2: Magnet properties after heat treatment at 800°C

[0040]

[0041] Combining the above tables 1 and 2, it can be seen that the coercive force of sample C is increased from 10.56kOe before heat treatment to heat treatment (DyH x Atmosphere 800℃ heat treatment + vacuum heat treatment) to 14.16kOe, an increase of 34.1%; w...

Embodiment 3

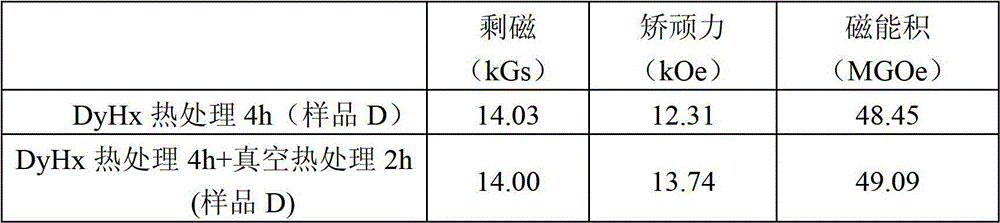

[0043] In this example, the test sample prepared in Example 1 is used.

[0044] A group of samples, Sample D, was taken out of the above test samples and subjected to heat treatment.

[0045] The heat treatment process of sample D is: sample D is buried in the same DyH in embodiment 1 x In the powder, heat treatment in vacuum at 700°C for 4 hours, and test its properties after heat treatment, as shown in the table below.

[0046] Then, sample D was placed in a sintering furnace, and subjected to vacuum heat treatment at 500° C. for 2 hours, and the properties of sample D were tested after heat treatment, as shown in Table 2 below.

[0047] Table 3: Magnet properties after heat treatment at 700°C

[0048]

[0049] Combining the above tables 1 and 3, it can be seen that the coercive force of sample D is increased from 10.56kOe before heat treatment to heat treatment (DyH x Atmosphere 700℃ heat treatment + vacuum heat treatment) to 13.74kOe, an increase of 30.1%; while the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com