Two-dimensional hot-film wind speed and direction sensor and preparation method thereof

A wind speed, wind direction, and sensor technology, which is applied in the use of thermal variables to measure fluid speed, instruments, speed/acceleration/impact measurement, etc., can solve the problems of low sensitivity and high power consumption of sensors, and achieve high sensitivity, high measurement accuracy, and responsiveness fast time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

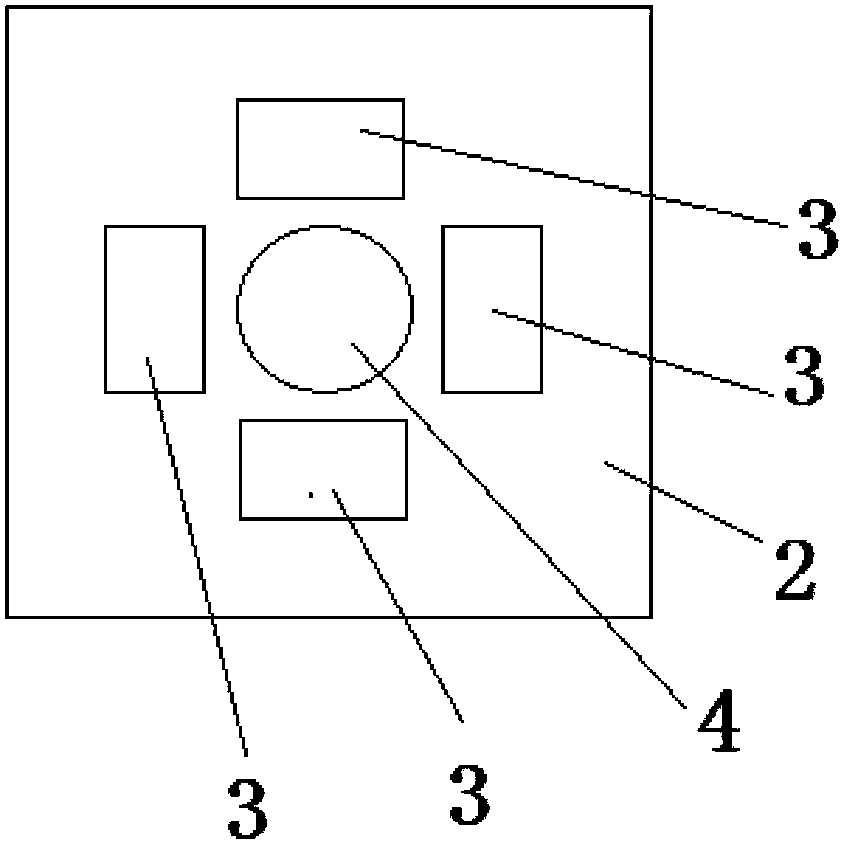

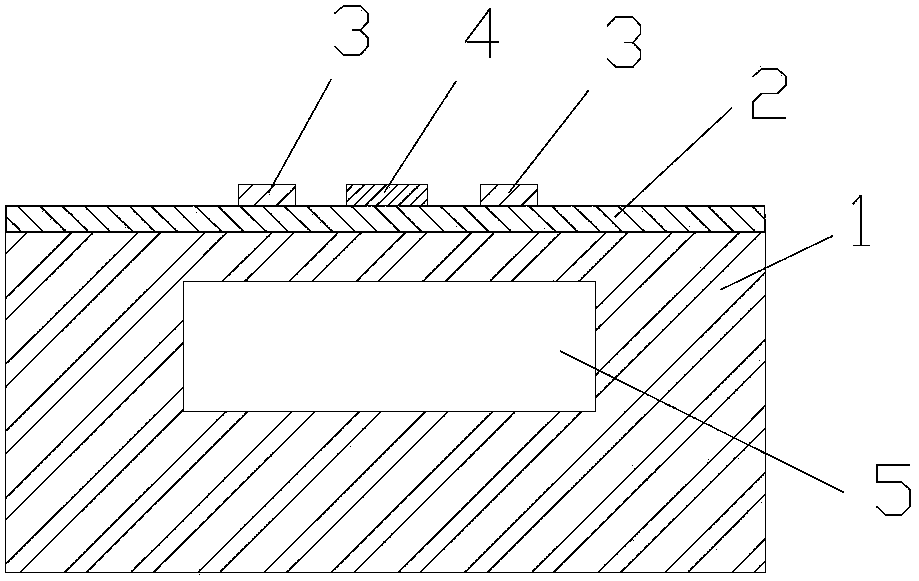

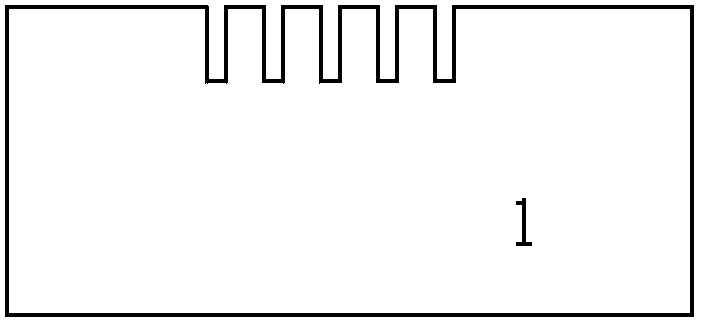

[0022] Such as figure 1 and figure 2 As shown, a two-dimensional hot film wind speed and direction sensor of the present invention includes a substrate 1 , an insulating layer 2 , a temperature measuring element 3 and a heating element 4 . The substrate 1 may be made of (100) oriented single crystal silicon. A cavity 5 is provided in the substrate 1, and the distance from the top surface of the cavity 5 to the top surface of the substrate 1 is less than 10 microns. The insulating layer 2 may be made of silicon dioxide. The insulating layer 2 is pasted on the upper surface of the substrate 1 , and the temperature measuring element 3 and the heating element 4 are respectively fixed on the upper surface of the insulating layer 2 . The thickness of the insulating layer 2 is preferably 0.5 to 2 microns. Setting the insulating layer 2 can pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com