Technique for recycling reject magnetic materials

A magnetic material and product recycling technology, applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of poor environmental protection, poor economic benefits, waste of energy, etc., achieve good environmental protection, increase output value and profit , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

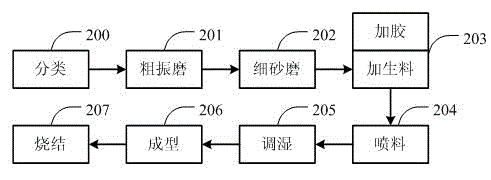

[0031] According to an embodiment of the present invention, a process for recycling and reusing poor magnetic material products is provided. Such as figure 2 As shown, this embodiment includes:

[0032] Step 200: Classification; that is, according to the type of magnetic material (power type and high permeability type), the same type of defective magnetic material products containing ferrous oxide, manganese oxide and zinc oxide of different sizes and shapes are processed Sort and clean up (ie, impurity removal treatment) to ensure that the defective magnetic material products after the impurity removal treatment are free of other impurities except the magnetic core;

[0033] Step 201: Coarse vibration grinding; that is, use a vibration grinder to vibrate the defective magnetic material products after classification and impurity removal treatment to obtain coarse materials with a particle size of no more than 10 μm; the finer the vibration grinding, the shorter the following Sand...

Embodiment 2

[0047] In this embodiment, the recycling process of the defective magnetic material product includes:

[0048] Step 1: Classification; that is, according to the type of magnetic material (power type and high permeability type), the same type of defective magnetic material products containing ferrous oxide, manganese tetraoxide and zinc oxide of different sizes and shapes are processed Sort and clean up (ie, impurity removal treatment) to ensure that the defective magnetic material products after the impurity removal treatment are free of other impurities except the magnetic core;

[0049] Step 2: Coarse vibration grinding; that is, use a vibration mill to vibrate and grind the classified and impurity-free magnetic material products to obtain a coarse material with a particle size of no more than 10 μm; the finer the vibration grinding, the shorter the following Sanding time

[0050] Step 3: Fine sanding; that is, use a sand mill to sand the coarse material obtained from the vibrator...

Embodiment 3

[0063] In this embodiment, the recycling process of the defective magnetic material product includes:

[0064] Step 1: Classification; that is, according to the type of magnetic material (power type and high permeability type), the same type of defective magnetic material products containing ferrous oxide, manganese tetraoxide and zinc oxide of different sizes and shapes are processed Sort and clean up (ie, impurity removal treatment) to ensure that the defective magnetic material products after the impurity removal treatment are free of other impurities except the magnetic core;

[0065] Step 2: Coarse vibration grinding; that is, use a vibration mill to vibrate and grind the classified and impurity-free magnetic material products to obtain a coarse material with a particle size of no more than 10 μm; the finer the vibration grinding, the shorter the following Sanding time

[0066] Step 3: Fine sanding; that is, use a sand mill to sand the coarse material obtained from the vibratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com