Power converting apparatus and capacitor cover thereof

A technology for power conversion devices and capacitors, applied in the direction of capacitors, tubular capacitors, power electronics modification, etc., can solve problems such as the inability to discharge the air inside the cover, and the inability to insert capacitors smoothly, and achieve the effect of maintaining cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, one embodiment will be described with reference to the drawings.

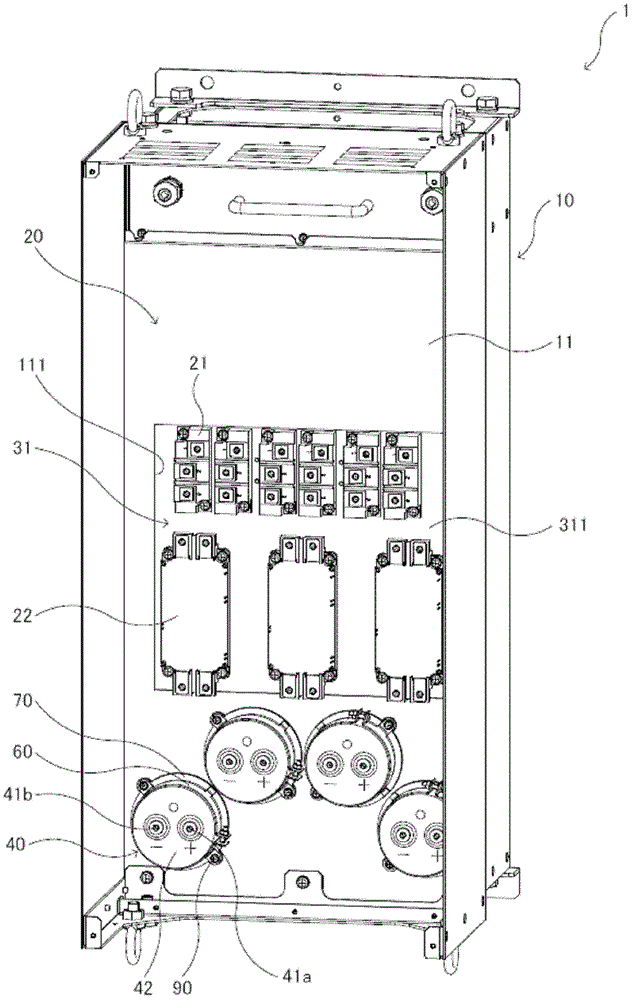

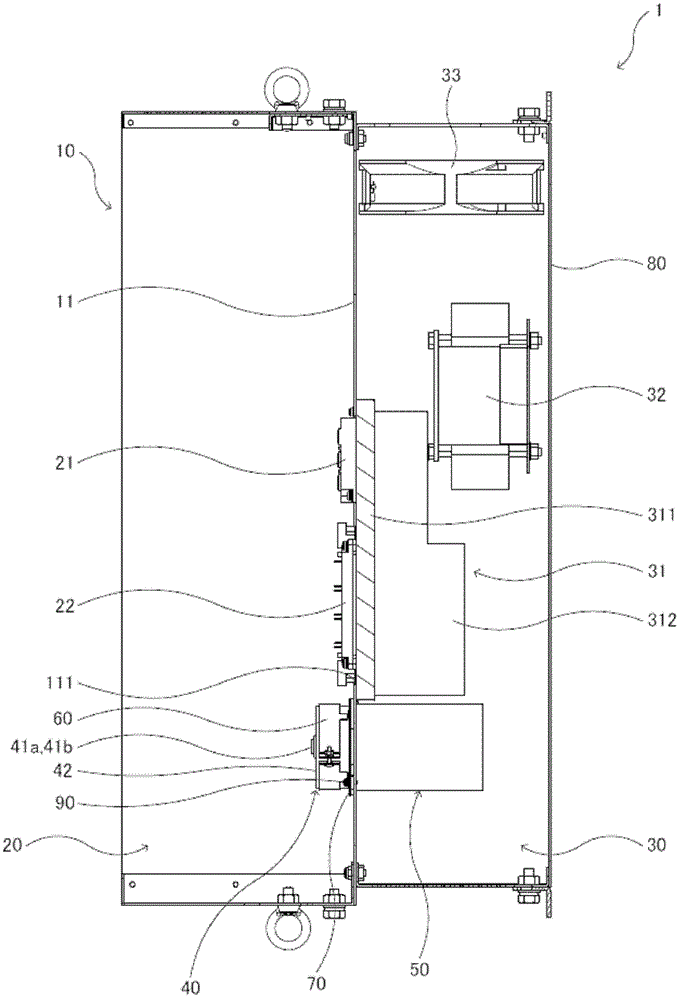

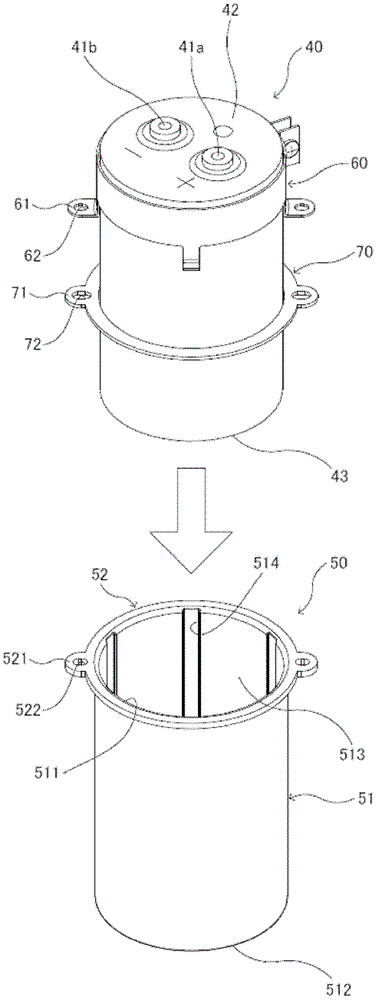

[0019] Such as figure 1 and figure 2 As shown, the power conversion device 1 of the present embodiment is an inverter device that converts DC power to AC power. This power conversion device 1 has: a frame 10 provided with a frame base 11; a main body 20 disposed on the front side (one side, figure 1 The left side and the front side of the paper, figure 2 the left side in); the wind tunnel part 30 is disposed on the rear side of the frame base 11 (the other side, figure 1 In the right side of the paper, into the deep side, figure 2 The right side of the middle), so that the cooling air flows; such as cylindrical capacitors 40 such as aluminum electrolytic capacitors; bottomed cylindrical capacitor cover 50; ring-shaped capacitor clip 60 (fixed member); ring-shaped metal plate 70 ; a body cover (not shown) covering the body portion 20 ; and a wind tunnel cover 80 covering the wind tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com