A parallel loop heat pipe heat dissipation device used for heat dissipation of a server chip

A technology of chip heat dissipation and loop heat pipe, which is applied in the direction of instruments, circuits, and electrical solid devices, can solve the problems of huge auxiliary supporting systems, limited heat dissipation efficiency, and cumbersome maintenance in the later stage, so as to improve safety and reliability, and improve heat dissipation The effect of temperature control level and overall thermal resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

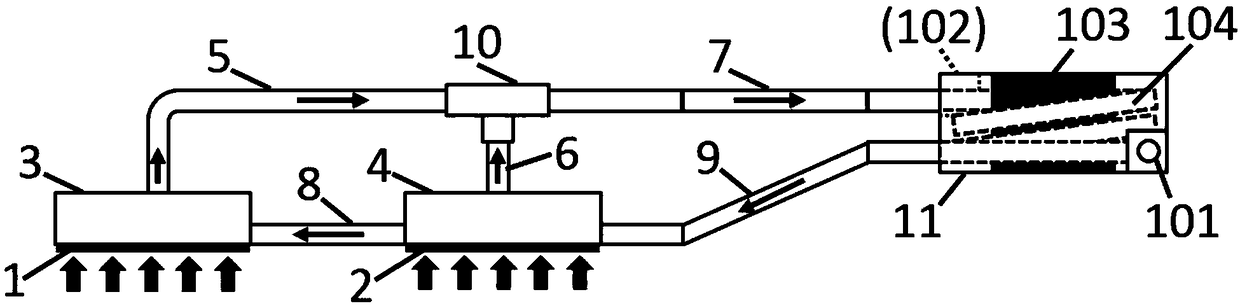

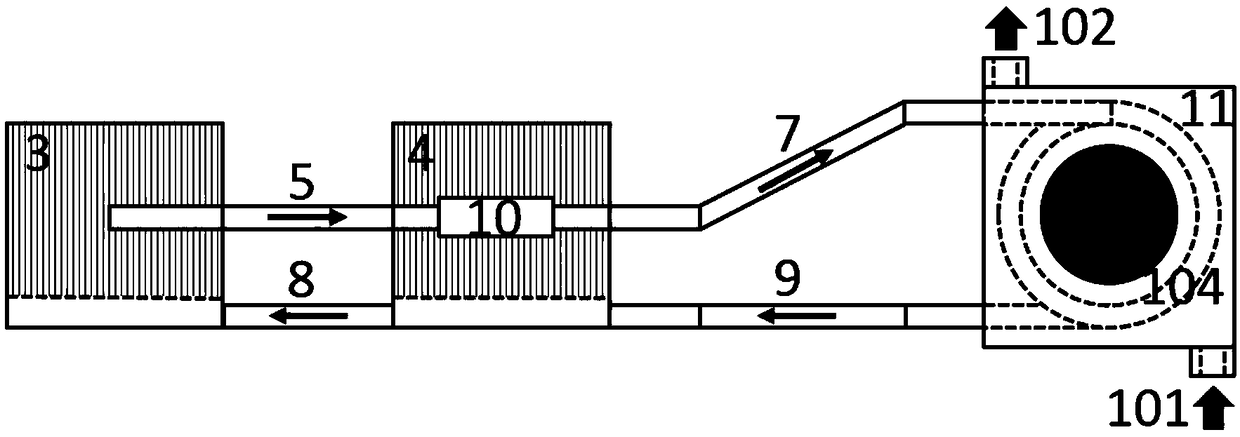

[0029] Referring to FIG. 1( a ) and FIG. 1( b ), there is shown a schematic structural diagram of a parallel loop heat pipe cooling device for cooling server chips in an embodiment of the present invention. In this embodiment, the parallel loop heat pipe cooling device used for server chip heat dissipation, the parallel loop heat pipe includes: a second evaporator 3, a first evaporator 4, a second gas pipeline 5, a first An evaporation pipeline 6 , a first gas pipeline 7 , a second liquid pipeline 8 , a first liquid pipeline 9 , a tee structure 10 , and a cooling box 11 .

[0030]The first liquid pipeline 9 is connected to the first evaporator 4, the first evaporator 4 is connected to the second evaporator 3 through the second liquid pipeline 8, and the second evaporator 3 is connected to the tee structure through the second gas pipeline 5 10. At the same time, the three-way structure 10 is connected to the first evaporator 4 through the first evaporation pipeline 6, and conne...

Embodiment 2

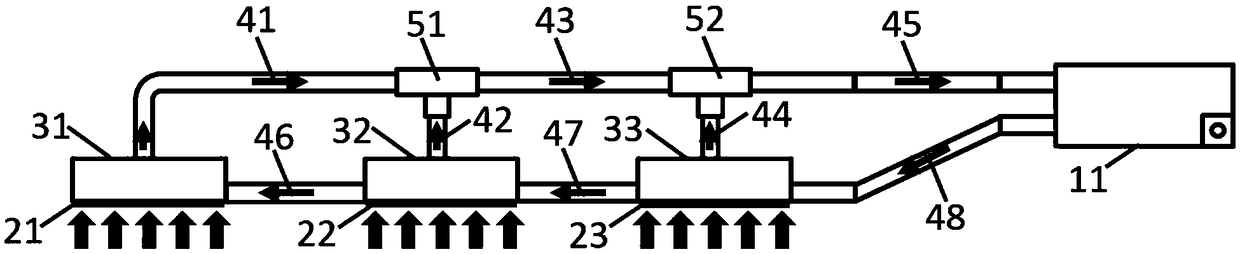

[0036] The present invention is not limited to the situation that two chips dissipate heat at the same time, and can be extended to three chips and is not limited to the situation that the CPU chip dissipates heat at the same time. Referring to FIG. 2( a ) and FIG. 2( b ), there is shown a schematic structural view of a three-evaporator parallel loop heat pipe cooling device for heat dissipation of server chips in an embodiment of the present invention.

[0037] In this embodiment, the parallel loop heat pipe cooling device used for server chip heat dissipation, the parallel loop heat pipe includes: a first evaporator 33, a second evaporator 32, a third evaporator 31, a first liquid Pipeline 48, second liquid pipeline 47, third liquid pipeline 46, third gas pipeline 41, second gas pipeline 43, first gas pipeline 45, second steam pipeline 42, first steam pipeline road 44 , the second three-way structure 51 , the first three-way structure 52 and the cooling box 11 .

[0038] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com