Sliding roller cutting fruit bag bag semi-automatic film cutting machine

A roll-cutting, semi-automatic technology, applied in metal processing and other directions, can solve the problems of wasting materials, affecting production efficiency, and not suitable for cutting thick strips of plastic film bags, so as to reduce product costs, facilitate adjustment and control, and improve The effect of film cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

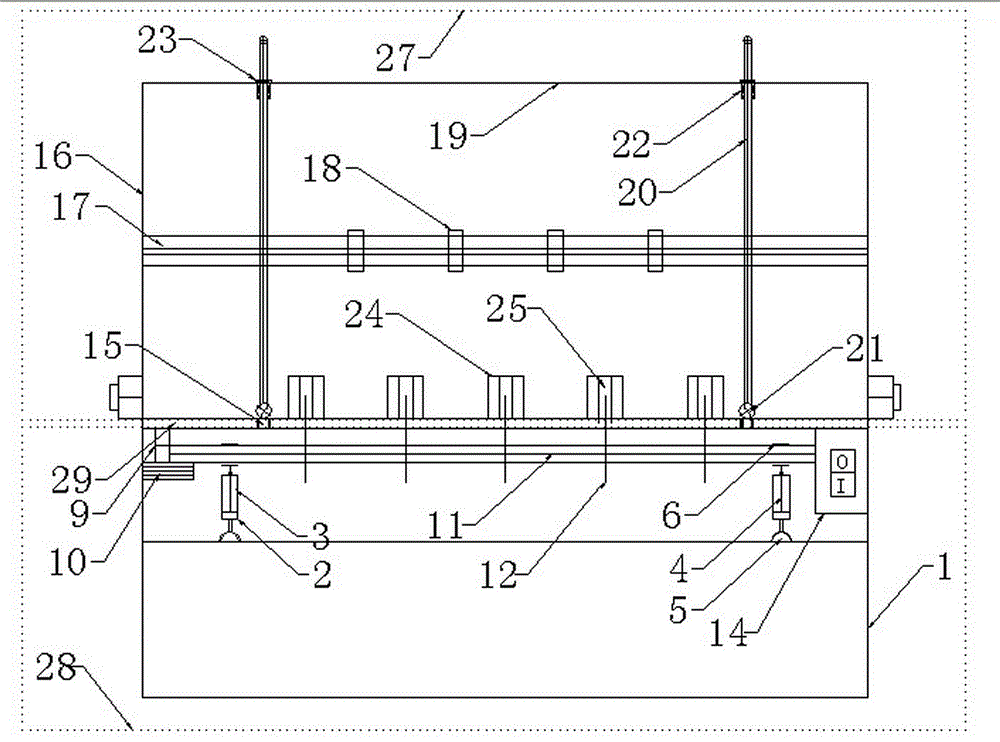

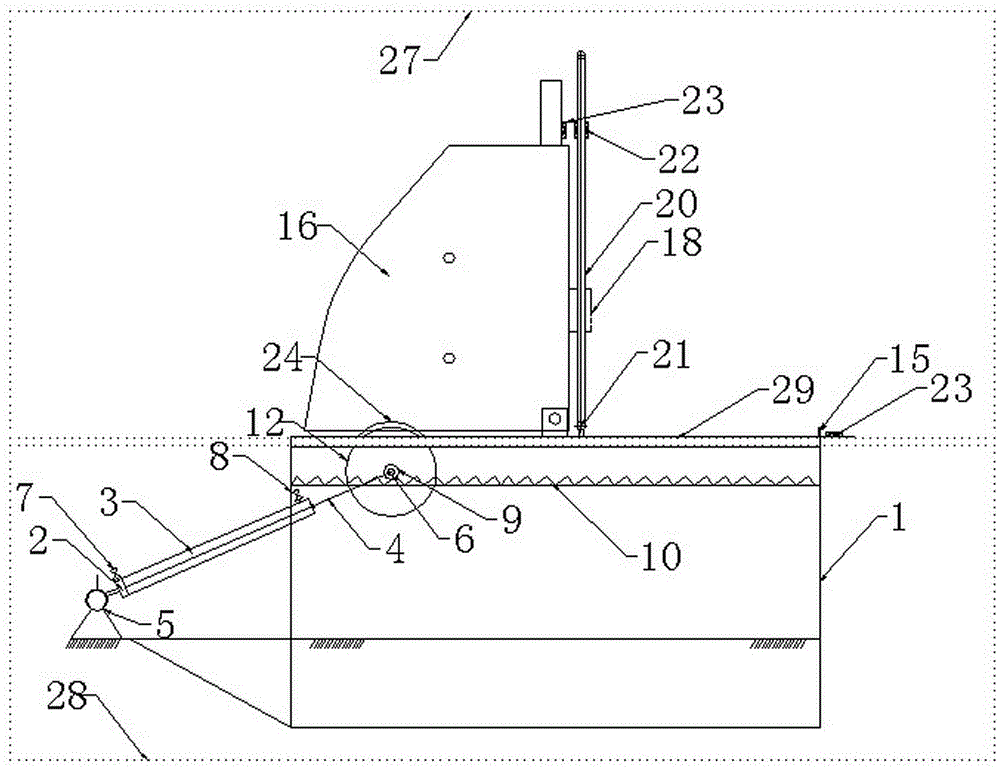

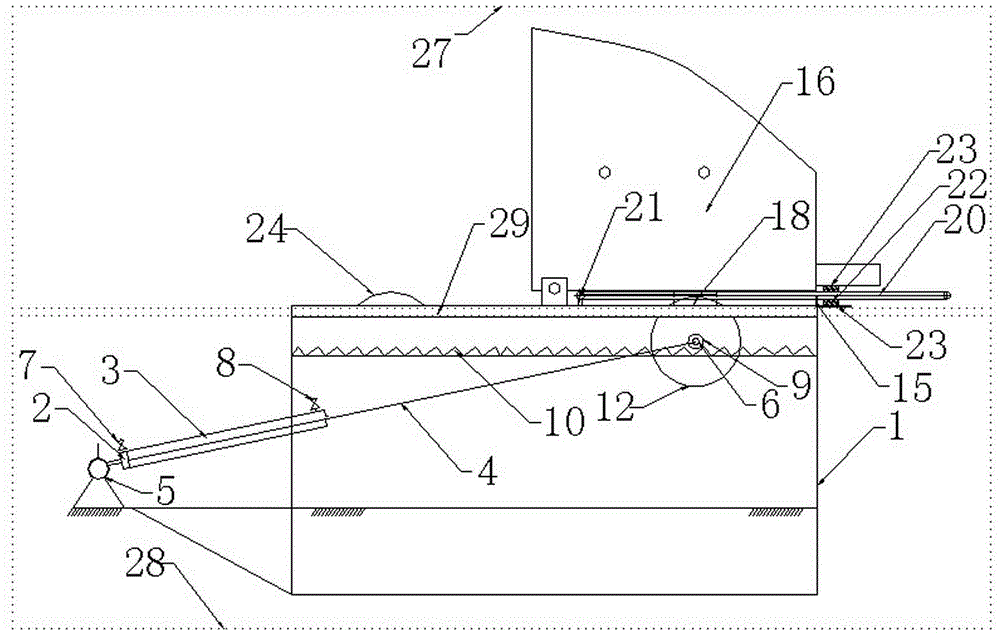

[0045] A semi-automatic film cutting machine for sliding roll cutting type fruit film bags, including a frame 1, and a film cutting device 28 and a fixed pressing device 27 arranged on the frame 1, the film cutting device 28 includes a film cutting device Work table top 29, guide rail groove 13, cylinder 2 and roller cutting disk cutter 12, described guide rail groove 13 is arranged on the film cutting work table top 29, described roller cutting disk cutter 12 is driven to rotate by cylinder 2, and roller cutting circle Disc cutter 12 reciprocates in guide rail groove 13; Described fixed pressing device 27 comprises pressing handle 20, and described pressing handle 20 is arranged on required cutting plastic film bag strip 26 top, and pressing handle 20 is used for Fix and compress the strip 26 of the plastic film bag.

[0046] A preferred embodiment of the present invention is that the cylinder 2 includes a cylinder block 3 and a piston guide rod 4, the cylinder 2 is fixedly a...

Embodiment 2

[0055] The structure of this embodiment is basically the same as that of the above-mentioned embodiment, and the difference is that: the film cutting table surface 29 is provided with an arc-shaped protective cover 24 that matches the working knife surface of the roller cutting disc knife 12, and the arc-shaped protective cover 24 is Preferably, an opening slot 25 is provided for the roller cutting disk knife 12 to pass through when cutting the film. The opening slot 25 can effectively prevent the operator from being injured during the film cutting process.

[0056] The implementation principle of this embodiment is that the plastic film bag strip 26 is placed on the film cutting work surface 29 on the frame 1, the placement direction of the plastic film bag strip 26 is perpendicular to the guide rail groove 13, and the plastic film bag length Bar 26 is in the motion locus of roller cutting disc cutter 12 in guide rail groove 13, and the cutting line of the plastic fruit baggin...

Embodiment 3

[0058] The structure of this embodiment is basically the same as that of the above-mentioned embodiment, the difference being that: the fixed pressing device 27 also includes two vertical plates 16, a pressing beam 17 and an operating beam 19, and the vertical plates 16 are respectively movably arranged in the cutting position by bolts. On both sides above the membrane working table surface 29 , the pressing beam 17 is arranged between the two vertical plates 16 , and the operating beam 19 is arranged between the two vertical plates 16 and above the pressing beam 17 .

[0059]The preferred implementation of this embodiment is that the pressing handle 20 includes a connecting end and an operating end, the connecting end is movably arranged on the film cutting workbench 29 through a hinge 21, a movable magnet 22 is arranged on the operating end, and the operating beam 19 and The film cutting workbench 29 is respectively provided with fixed magnets 23 corresponding to the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com