Preparation method of piezoelectric ceramic spherical shell

A piezoelectric ceramic and spherical shell technology, which is applied in the field of piezoelectric ceramic spherical shell preparation, can solve the problems of restricting the omnidirectional underwater acoustic transducer, high preparation cost, unstable performance, etc., and achieves strong universality of powder. , The effect of short production cycle and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

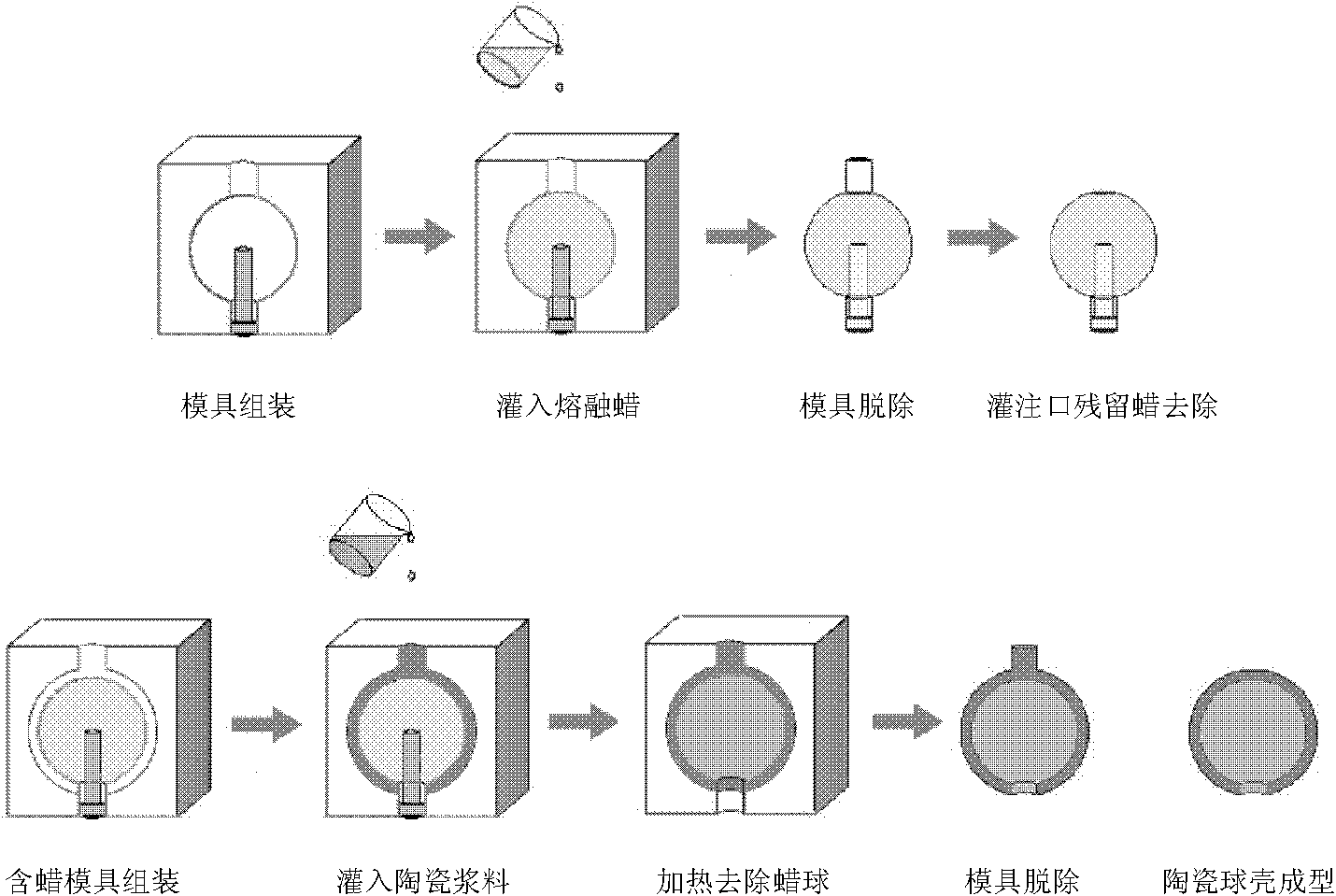

Method used

Image

Examples

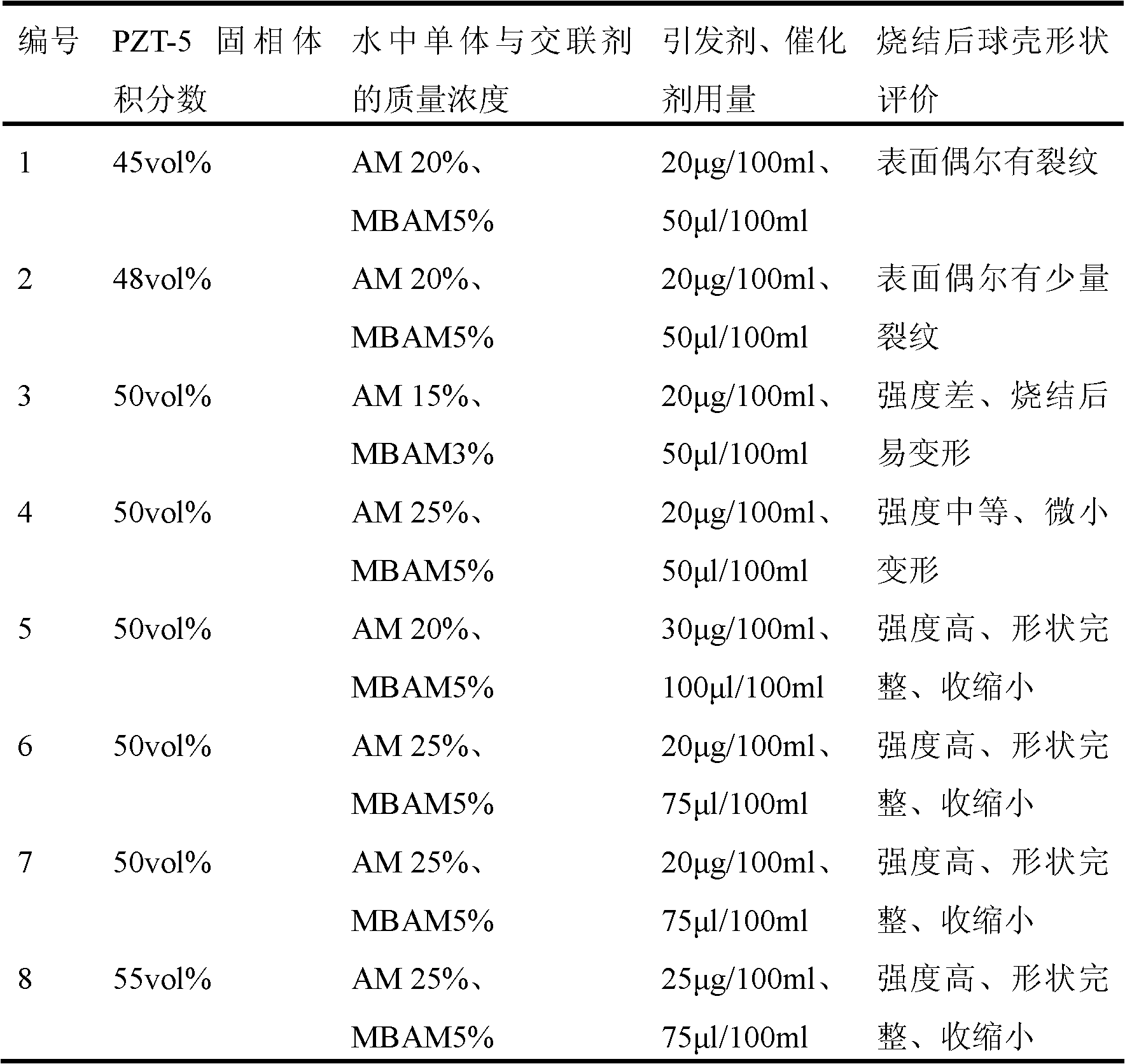

Embodiment 1

[0027] Mix 4g of acrylamide (AM), 1g of N,N'-methylenebisacrylamide (MBAM), 65g of lead zirconate titanate powder and 1g of dispersant ammonium citrate with 10g of deionized water to obtain a volume fraction of about It is about 19ml of 45Vol% low-viscosity ceramic slurry. After vacuuming and defoaming, add 2μg initiator and 10ul catalyst. After stirring evenly, pour it into a metal mold with a ball cavity inner diameter of 1.2cm and a central fixed diameter of 1cm wax ball. Put it in an oven at 60°C for 1 hour to solidify the slurry, then raise the temperature to 80°C to remove the inner mold of the wax ball; after the wax ball is removed, take the formed hollow ceramic spherical shell out of the mold, and place it at 30-40°C for 72 Continue to solidify and dry for hours; then remove the thin column left at the pouring port to make a hollow ceramic spherical shell green body with a strength greater than 10Mpa; keep the hollow ceramic spherical shell green body at 550°C for 2 h...

Embodiment 2

[0029]Mix 12g of acrylamide (AM), 2.4g of N,N'-methylenebisacrylamide (MBAM), 682g of lead zirconate titanate powder and 1g of dispersant sodium polyacrylate with 80g of deionized water to obtain the volume fraction About 162ml of low-viscosity ceramic slurry of about 52Vol%, after vacuuming and defoaming, add 40μg of initiator and 130ul of catalyst, after stirring evenly, pour it into a metal mold with a ball cavity inner diameter of 10cm and a central fixed diameter of 8.8cm wax ball , put it in an oven at 60°C for 2 hours to solidify the slurry, then raise the temperature to 80°C to remove the inner mold of the wax ball; after the wax ball is removed, take the formed hollow ceramic spherical shell out of the mold, and place it at 30°C for 4 days Continue curing and drying; then remove the thin column left at the pouring port to make a hollow ceramic spherical shell green body with a strength greater than 10Mpa; keep the hollow ceramic spherical shell green body at 550°C for ...

Embodiment 3

[0031] Mix 4g methacrylamide (MAM), 1g N, N'-methylenebisacrylamide (MBAM), 190g lead zirconate titanate powder and 0.5g dispersant sodium polyacrylate with 20g deionized water to obtain About 42ml of low-viscosity ceramic slurry with a volume fraction of about 55Vol%, after vacuuming and defoaming, add 8μg initiator and 20μl catalyst. In the mold, place it in an oven at 60°C for 1.5 hours to solidify the slurry, then raise the temperature to 80°C to remove the inner mold of the wax ball; ℃ for 72 hours to continue to solidify and dry; then remove the thin column left at the pouring port to make a hollow ceramic spherical shell green body with a strength greater than 10Mpa; keep the hollow ceramic spherical shell green body at 550°C for 1 hour, and then in Sintering at 1265°C for 2.5 hours to obtain a piezoelectric ceramic spherical shell with an outer diameter of 3.12 cm, an inner diameter of 2.6 cm, and a wall thickness of 0.52 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com