Splitting process of racemic para hydroxybenzene glycine

A technology of L-p-hydroxyphenylglycine and p-hydroxyphenylglycine, which is applied in the field of splitting technology of mixed-rotational p-hydroxyphenylglycine, can solve the problems of low conversion rate, expensive resolving agent, complicated process, etc., and reduce the discharge of three wastes , increase the utilization rate of raw materials, the effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope of the examples.

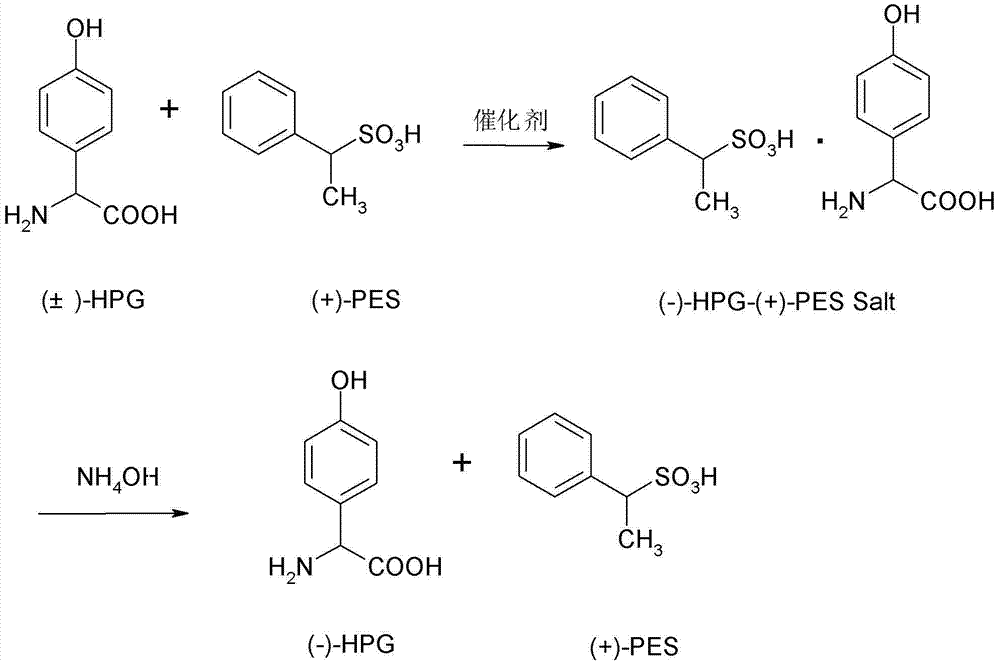

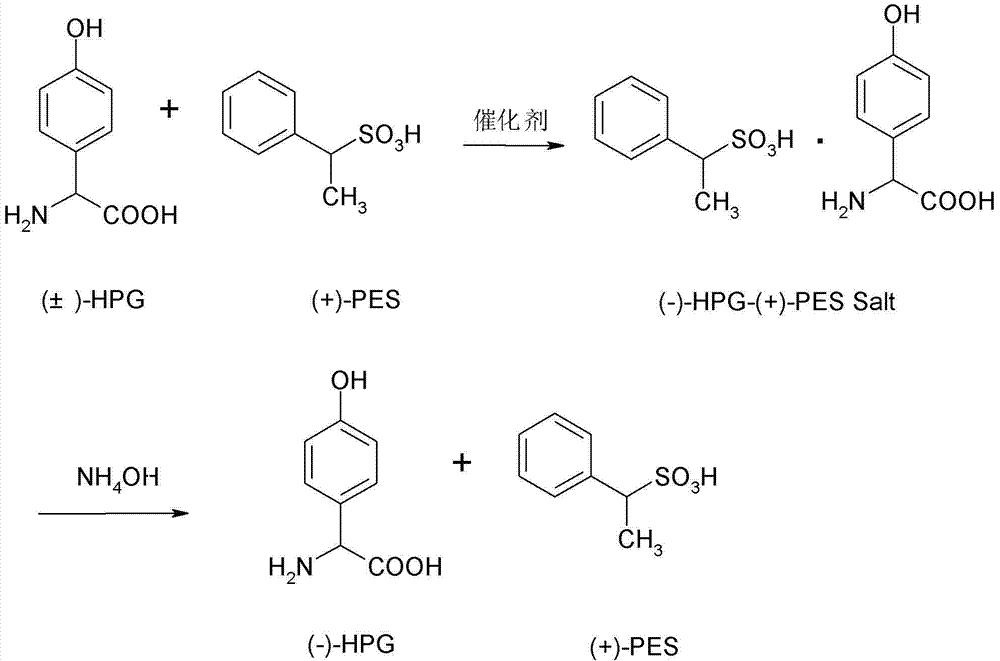

[0010] A kind of splitting equation of the splitting technique of mixed-rotation p-hydroxyphenylglycine is as follows:

[0011]

[0012] In the above formula, (±)-HPG is mixed p-hydroxyphenylglycine, (+)-PES is right-handed phenylethylsulfonic acid, (-)-HPG-(+)-PES Salt is left-handed p-hydroxyphenylglycine and right-handed The double salt formed by phenylethanesulfonic acid, (-)-HPG is the target product L-p-hydroxyphenylglycine.

[0013] 2) Split process:

[0014] Hydrolysis process: complex dispersion of 1mol of L-p-hydroxyphenylglycine and D-phenylethylsulfonic acid in 20mol of water, slowly adding inorganic alkali solution (including but not limited to sodium hydroxide aqueous solution, ammonia water, potassium hydroxide aqueous solution, etc., Preferably sodium hydroxide aqueou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com