Silicate red fluorescent powder and preparation method thereof

A technology of red fluorescent powder and silicate, which is applied in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of affecting the use effect, reducing light efficiency, and difficulty in obtaining white light with high color rendering. Effects of reduction, optimization of crystal field, improvement of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

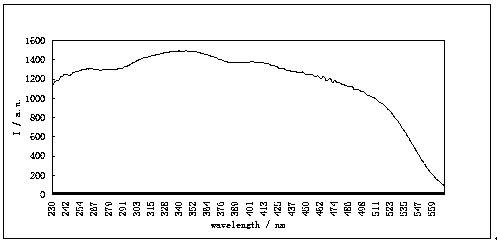

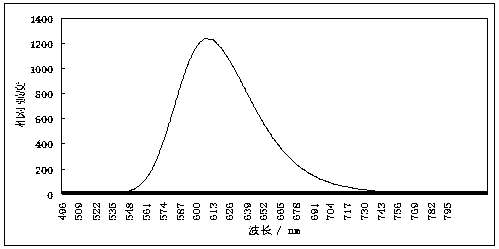

[0032] Weigh BaCO 3 13.16g, SrCO 3 134.15g, LiF0.2g, Si 3 N 4 13.09g, Eu 2 o 3 3.22g, CeO 2 0.57g, NH 4 F0.74g, mixed evenly and put into corundum crucible, in reducing atmosphere (N 2 and H 2 The volume ratio is 10:90), heated to 1364 ° C, and kept for 12 hours; the fired powder was crushed, sieved, washed with deionized water until neutral, dried, and finally vinyl three (β- Methoxyethoxy) silane for dry surface modification, the prepared composition is Sr 2.726 Ba 0.2 Li 0.023 Si 0.84 Ge 0.16 OF 0.083 :Eu 0.055 , Ce 0.01 Silicate red phosphor, its emission spectrum, excitation spectrum and X-ray diffraction spectrum are shown in figure 1 , figure 2 and Figure 4 . Depend on Figure 4 It can be seen from the color spectrum that the phosphor powder in Example 1 is pure in phase and has no impurity. The full spectrum of the positive white LED prepared by using this phosphor is shown in Figure 6 .

Embodiment 2

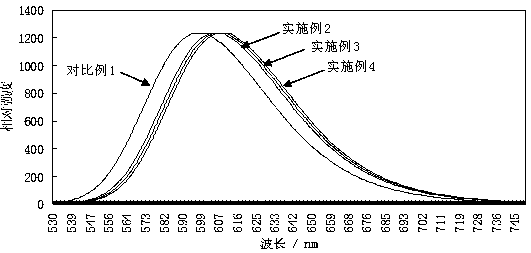

[0034] Weigh BaCO 3 9.21g, SrCO 3 137.79g, Si 3 N 4 15.43g, NaF0.168g, P 2 o 5 0.473g, Eu 2 o 3 4.34g, MnCO 3 0.3g, mixed evenly and put into corundum crucible, in reducing atmosphere (N 2 and H 2 The volume ratio is 20:80), heated to 1480°C, and kept warm for 6.5h; the fired powder was crushed, sieved, washed with deionized water until neutral, dried, and finally vinyl three (β -Methoxyethoxy)silane after dry surface modification, the prepared composition is Sr 2.8 Ba 0.14 Na 0.012 Si 0.99 P 0.01 o 4.96 f 0.012 :Eu 0.074 , Mn 0.0078 Silicate red phosphor, its emission spectrum see image 3 .

Embodiment 3

[0036] Weigh BaCO 3 13.16g, SrCO 3 130.65g, Si 3 N 4 13.87g, KF0.62g, P 2 o 5 2.6g, Eu 2 o 3 5.86g, Dy 2 o 3 0.8g, mixed evenly and put into corundum crucible, in reducing atmosphere (N 2 and H 2 The volume ratio is 40:60), heated to 1520°C, and kept for 6 hours; the fired powder was crushed, sieved, washed with deionized water until neutral, dried, and finally washed with 3-(2-ammonia After ethyl)-aminopropylmethyldimethoxysilane carries out dry method surface modification, the prepared composition is Sr 2.655 Ba 0.2 K 0.032 Si 0.89 P 0.11 o 5.3 f 0.04 :Eu 0.1 , Dy 0.013 Silicate red phosphor, its emission spectrum see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminous efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com