Control method for RH vacuum processing mode

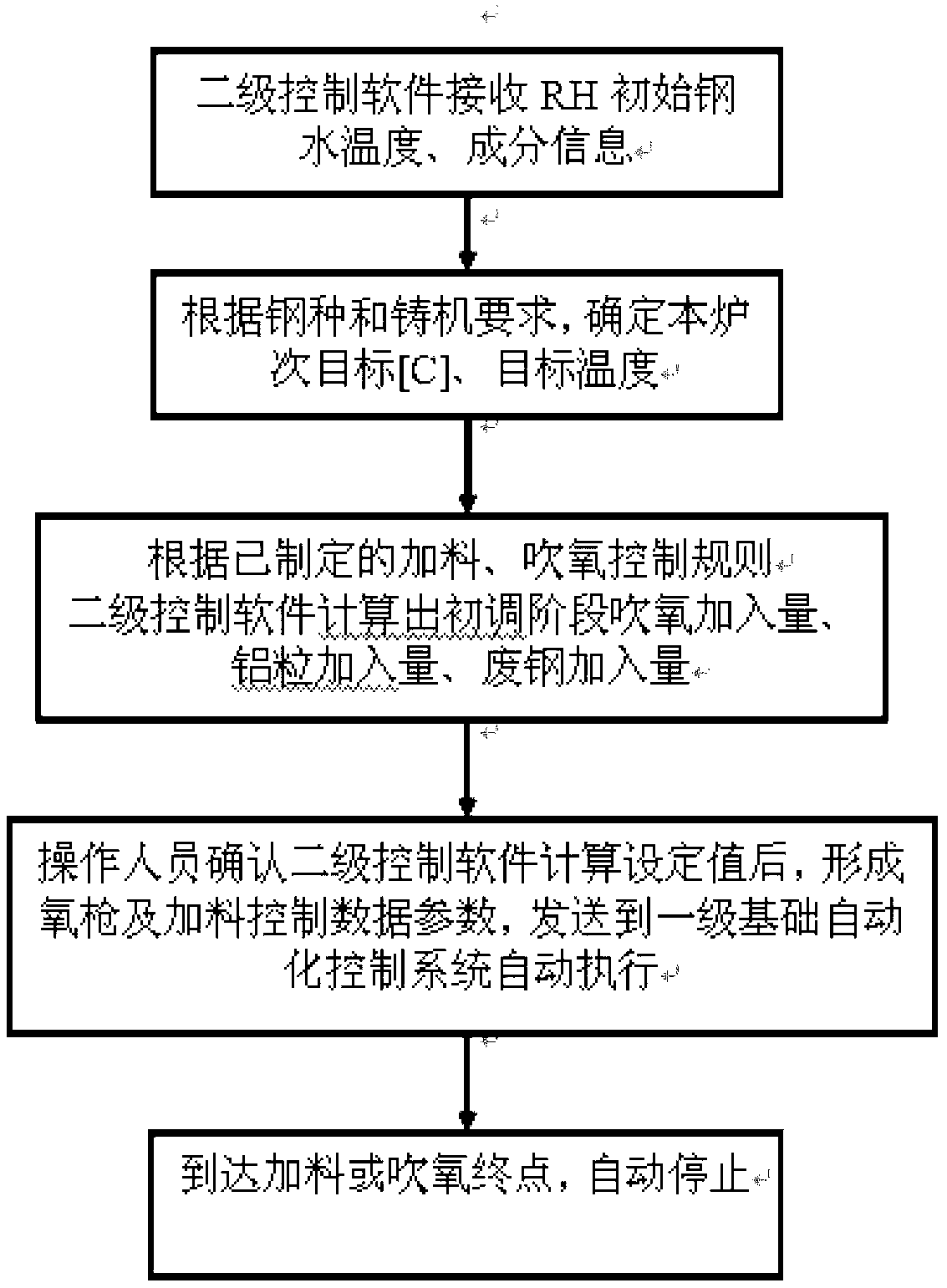

A light processing and mode technology, applied in the control field of RH light processing mode, can solve the problems of limited model accuracy and poor self-adjustment ability of the model, and achieve the effect of standard operation, convenient automatic control and high automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the control method of the present invention, the factors that affect the pre-adjustment of aluminum in the initial adjustment stage of molten steel are divided into two categories, one is that the molten steel [O] is greater than 400ppm when the forecast decarburization ends; the other is that the forecast vacuum end temperature is lower than the target temperature , add aluminum to heat up.

[0050] In addition, when the predicted vacuum end temperature is higher than the target temperature, it is difficult to quantify the temperature drop rate of molten steel due to uncertain factors such as the initial ladle thermal state. The specific implementation manners of the present invention will be described in detail below.

[0051] (1) Smelting furnace number: 121B03523

[0052] Vacuum initial temperature: 1612°C;

[0053] Initial [C] content: 0.051%, initial [O] content: 335ppm, target [C] content: 0.03%;

[0054] Target temperature at the end of vacuum: 1592°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com