Method for roasting siderite and shaft furnace

A technology of shaft furnace and furnace chamber, which is applied in the field of roasting siderite, method and shaft furnace, which can solve the problems of unfavorable environmental protection and environmental pollution, and achieve the effects of increasing production, reducing pollution and uniform roasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

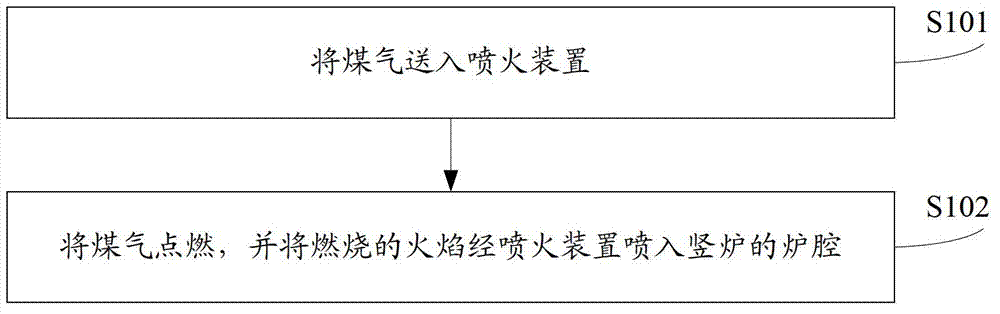

[0046] Embodiment 1 of the present invention provides a kind of method of roasting siderite, see figure 1 ,include:

[0047] Step S101: sending coal gas into the flame injection device;

[0048] Step S 102: ignite the gas, and spray the burning flame into the furnace cavity of the shaft furnace through the flame injection device.

[0049] In the method for roasting siderite provided by Embodiment 1 of the present invention, coal gas is introduced into the flame injection device of the shaft furnace, and the gas is ignited, and the burning flame is sprayed into the furnace cavity of the shaft furnace through the flame injection device, and then the furnace is heated. The siderite in the cavity is roasted. In this way, compared with the combustion of raw coal, gas is directly introduced for combustion, which can reduce environmental pollution.

Embodiment 2

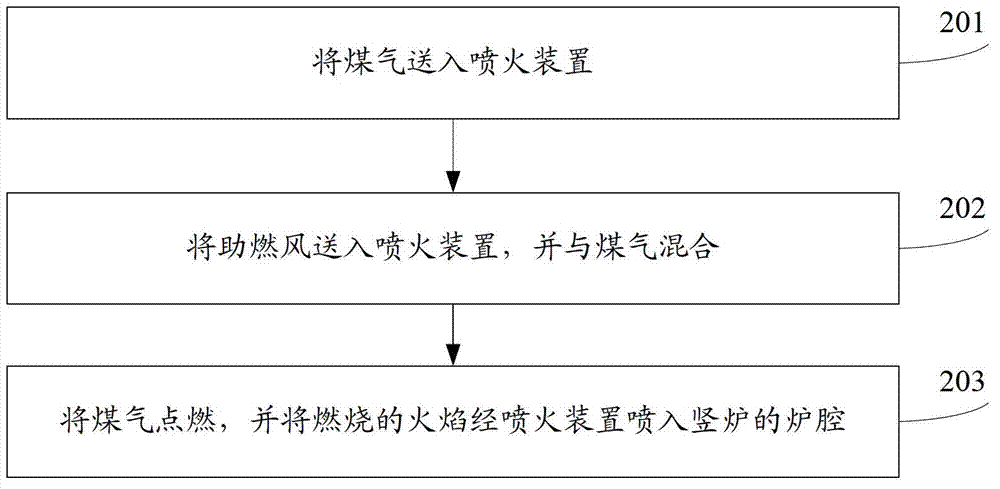

[0051] Embodiment two of the present invention provides another method for roasting siderite, see figure 2 ,include:

[0052] Step 201: sending the gas into the flame injection device;

[0053] Preferably, in this embodiment, the coal gas is the coal gas produced by the gas generator, which is sent into the flame injection device through the delivery pipeline;

[0054] Different from the direct combustion of raw coal in the prior art, and then the siderite is roasted by the burning flame, in the second embodiment of the present invention, the siderite is roasted by using the gas of the gasifier, because the gas produced by the gasifier There is less impurity gas, and the content of carbon monoxide is low, and the pollution to the environment is low, which is in line with the concept of environmental protection;

[0055] Step 202: sending the combustion-supporting air into the flame injection device, and mixing it with the gas;

[0056] Among them, the combustion-supporting...

Embodiment 1

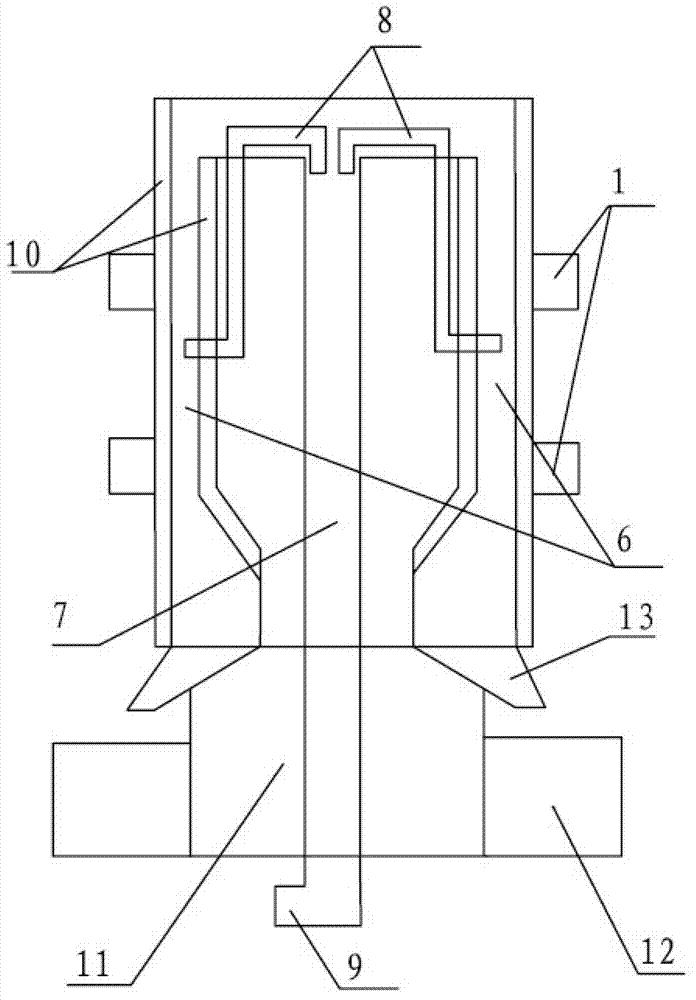

[0061] For embodiment one, embodiment three of the present invention provides a kind of shaft furnace of roasting siderite, comprising:

[0062] A flame-throwing device, the outer wall of which is provided with gas inlets and nozzles;

[0063] The gas inlet is communicated with the nozzle;

[0064] The nozzle communicates with the furnace cavity of the shaft furnace.

[0065]Since the outer wall of the fire injection device is provided with gas inlets and nozzles, compared with the prior art where the raw coal burning flame is directly blown into the furnace cavity, the gas burning flame is sprayed into the furnace cavity through the nozzle in the present invention, so that the flame and the furnace The siderite in the cavity is fully contacted and roasted evenly, which further improves the output of roasted siderite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com