Semiconductor epitaxial wafer substrate-bearing disk, supporting device thereof and metal organic chemical vapor deposition (MOCAD) reaction chamber

A technology for reaction chambers and loading trays, applied in the field of support and rotary connection devices, can solve the problem of not being easy to ensure the verticality of the loading tray and the axis of the rotating shaft, affecting the service life of the rotating shaft and the loading tray, and controlling the speed of the loading tray Inaccurate and other issues, it is not easy to slide relative to each other, it is conducive to growth, and the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

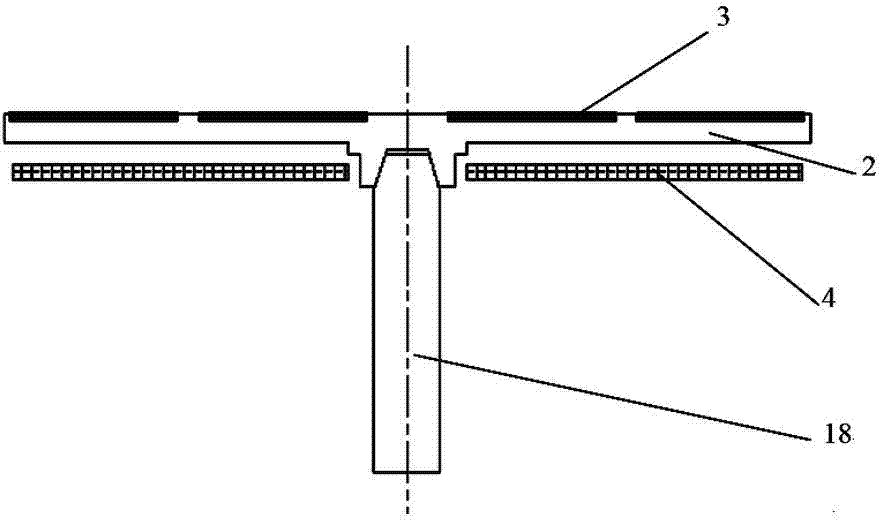

[0051] In this embodiment, there is no groove 16 on the lower surface of the slide tray 2; Figure 6 As shown, the lower part of the circular outer surface 21 of the loading disk 2 is designed as a conical surface 23; The slide disc 2 is coupled to the hollow rotating shaft 6 via the two conical surfaces 23 , 62 . The positioning of the slide tray 2 is accomplished through the pair of coupled conical surfaces 23, 62, and the rotating shaft 6 drives the slide tray 2 to rotate through the coupling taper surfaces.

[0052] Other structures are similar to Embodiment 1 and will not be repeated here.

Embodiment 3

[0054] In this example, if Figure 7 Shown; There is no groove 16 on the lower surface of the loading disc 2, and the bottom of the circular outer surface 21 of the loading disc 2 is recessed inwardly to form a conical surface structure, but the maximum diameter of the conical surface is larger than the diameter of the circular outer surface It should be small, so that the top of the loading disk 2 forms a flange, and there is an annular surface 22 under the flange; The end face also has a circular surface 64 . The slide disc 2 is coupled to the rotating hollow shaft 6 through a tapered surface. At this time, there is a slight gap between the annular surface 22 below the flange and the annular surface 64 on the top of the hollow shaft 6 . The slide tray 2 is positioned through the coupled conical surface, and the hollow shaft 6 drives the slide tray 2 to rotate through the coupled cone surface.

[0055] The lower part of the circular outer surface of the loading disk 2 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com