Electric fuel pump

An electric fuel pump and pump chamber technology, which is applied in the field of fuel pressurization devices, can solve the problems of hindering work, not getting flow and pressure, and the oil pump is difficult to work normally, so as to achieve the effect of uniform friction and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

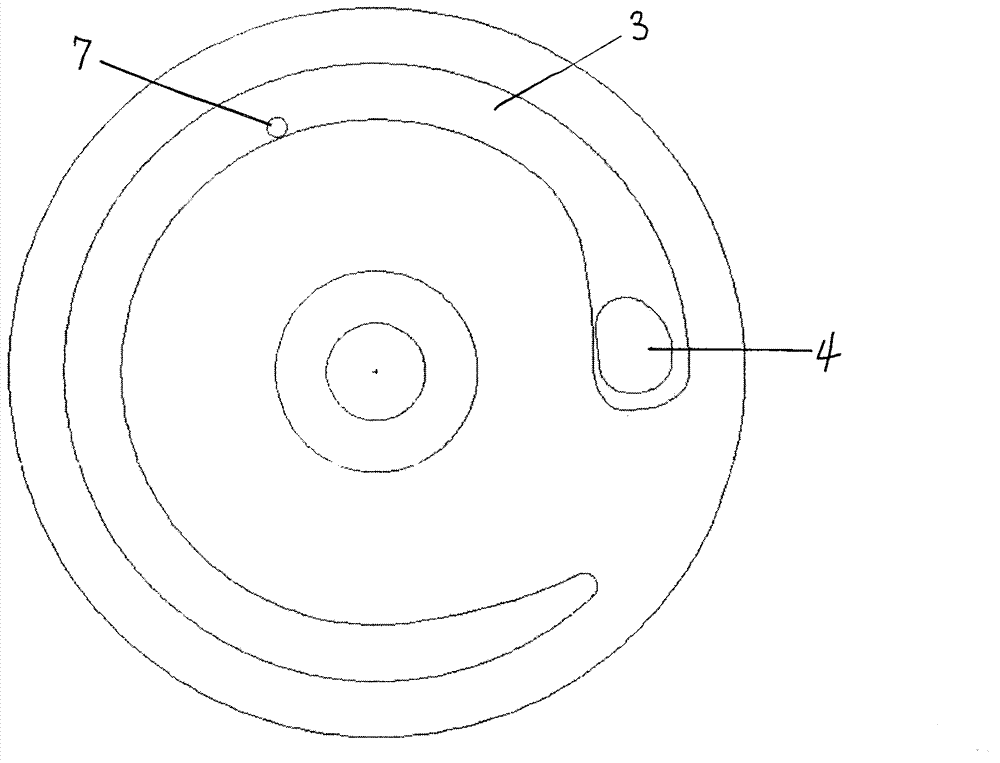

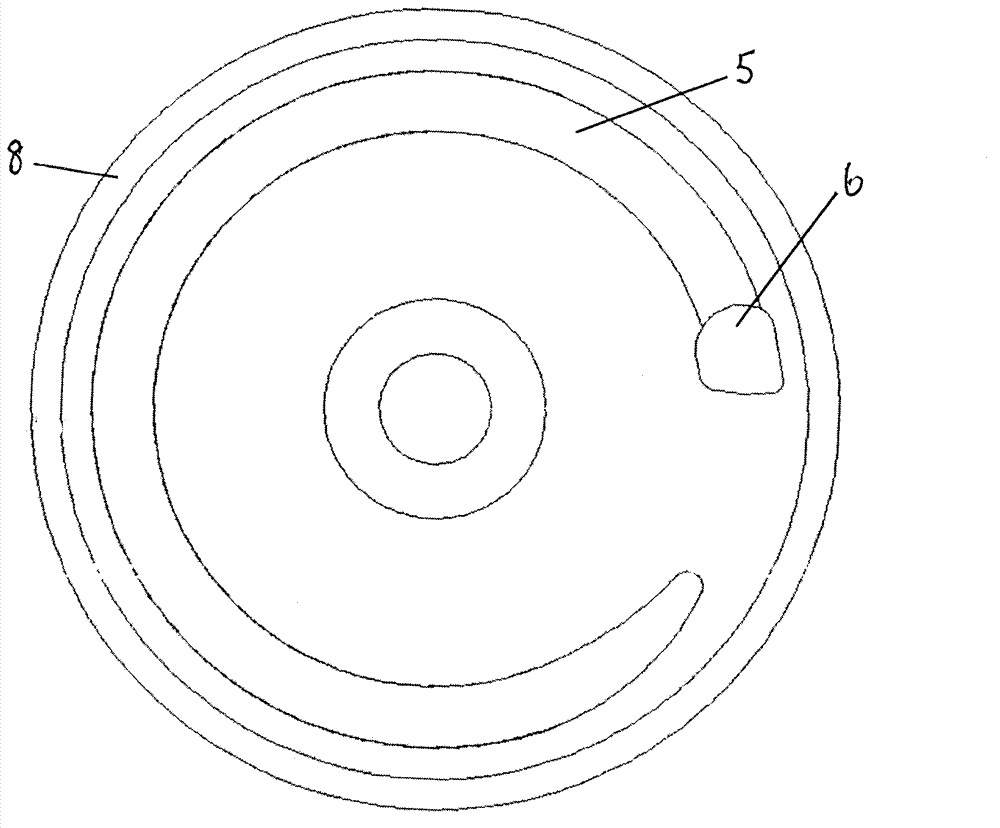

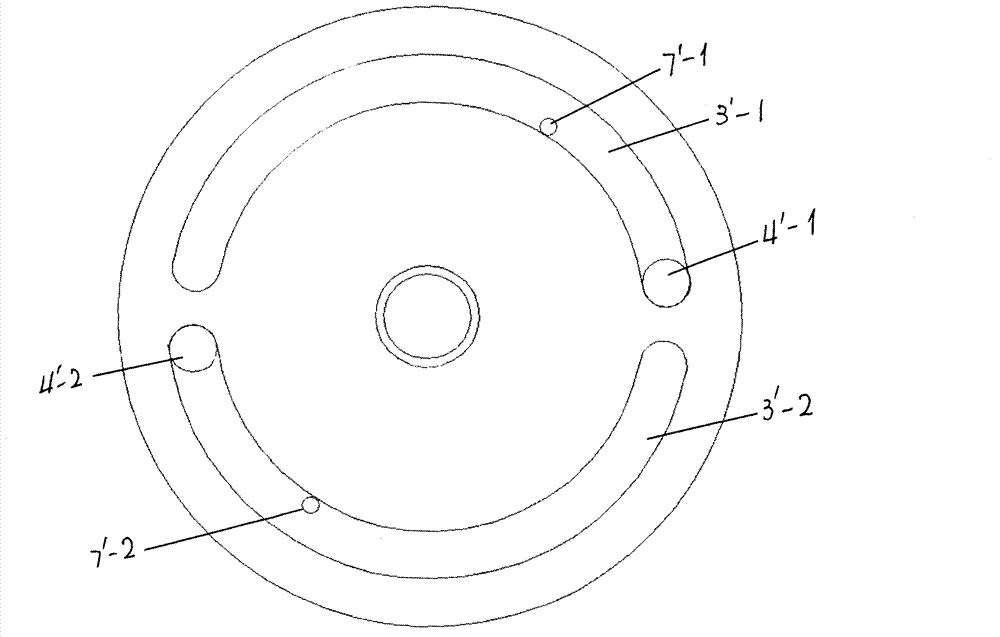

[0018] An electric fuel pump, which includes a circular pump chamber, the pump chamber is composed of two shells and an impeller, the lower shell 1' is a circular flat plate, and the upper shell 2' has a circle of protrusions around it The shoulder is 8' and the shoulder height is 4mm, forming a circular box shape, which matches the impeller, and the impeller is seated in it. Sheet 2' caps are tightly sealed to form pump chambers such as image 3 and 4 As shown, there are two concave arc-shaped first oil inlet grooves 3'-1 and second oil inlet grooves 3'-2 connected end to end and concentric with the casing on the inner bottom surface of the lower part 1' of the casing. The arc length of each oil inlet groove 3' is 175 degrees. 'The first oil inlet hole 4'-1 and the second oil inlet hole 4'-2, the tail ends of the first oil inlet groove 3'-1 and the second oil inlet groove 3'-2 gradually become shallow and terminate. An oil inlet groove 3'-1 has a first drain hole 7'-1 pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com