Intelligent Bolt Sensor and Calibration Method

An intelligent, sensor-based technology, applied in instruments, signal transmission systems, calibration/testing of force/torque/power measuring instruments, etc., can solve problems such as difficulty in meter reading, difficulty in meter calibration of bolt sensors, etc., and achieve sudden interference And the effect of sensitivity improvement, automatic filtering of errors and false information, and good stabilization function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the intelligent anchor sensor is further described with reference to the accompanying drawings.

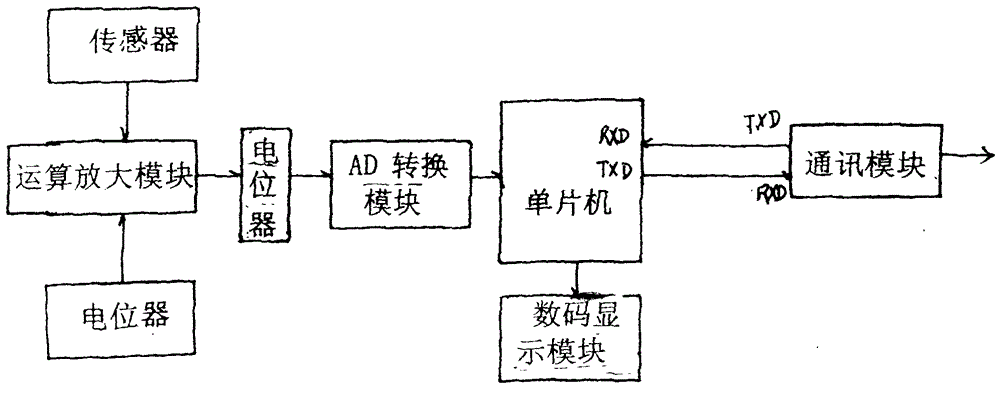

[0032] figure 1 It is the schematic block diagram of the circuit of the existing bolt sensor. It can be seen from the figure that it is composed of a single chip microcomputer, a communication module RSM3485, an AD conversion module, a digital display module, an operational amplifier, a resistance bridge type stress sensor and a calibration potentiometer.

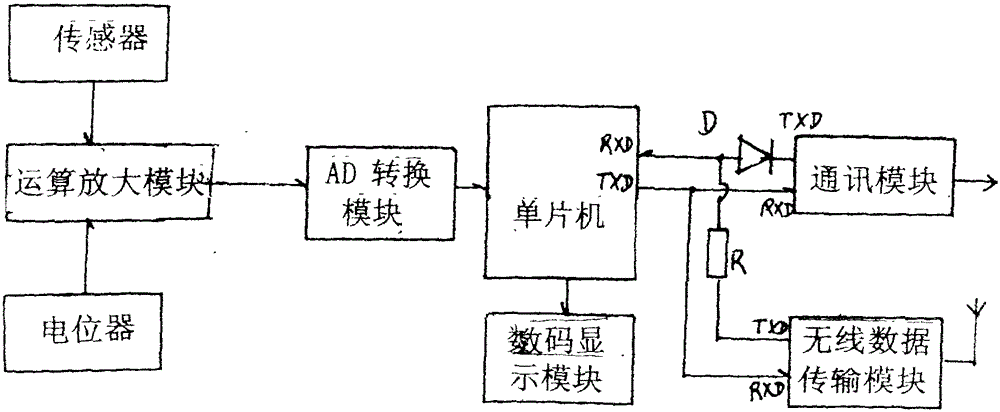

[0033] figure 2 It is a block diagram of the circuit principle of the embodiment of the intelligent anchor sensor of the present invention. It can be seen from the figure that it is composed of a single-chip microcomputer, a communication module RSM3485, an AD conversion module, a digital display module, an operational amplifier OPO7BP, and a resistance bridge stress sensor. ; It also includes a wireless data transmission module; the wireless data transmission module adopts the highly integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com