Intelligent mine pressure monitoring sub-station and its calibration method

A monitoring sub-station, intelligent technology, applied in the direction of force/torque/work measuring instrument calibration/test, measuring force, measuring device, etc. Achieve the effect of low power consumption, cost reduction, and strong diffraction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

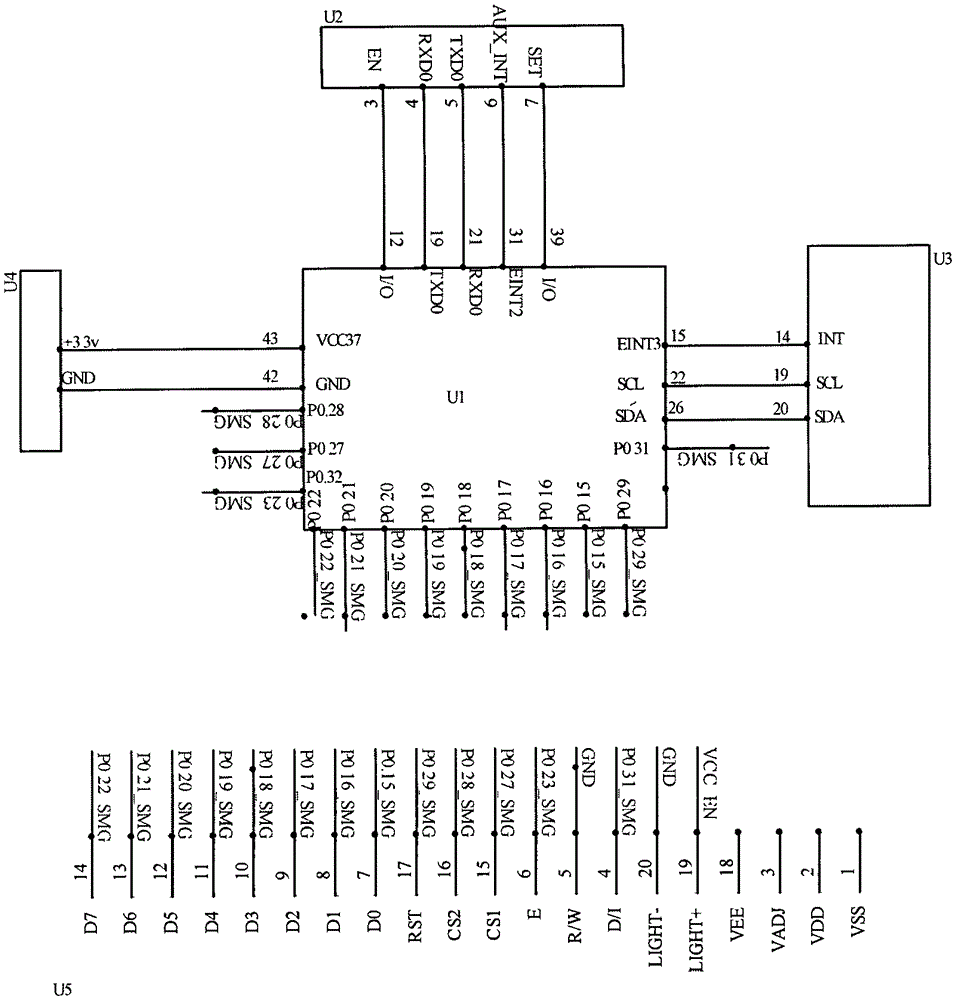

[0030] The technical scheme of the intelligent mine pressure monitoring substation is further described with reference to the accompanying drawings.

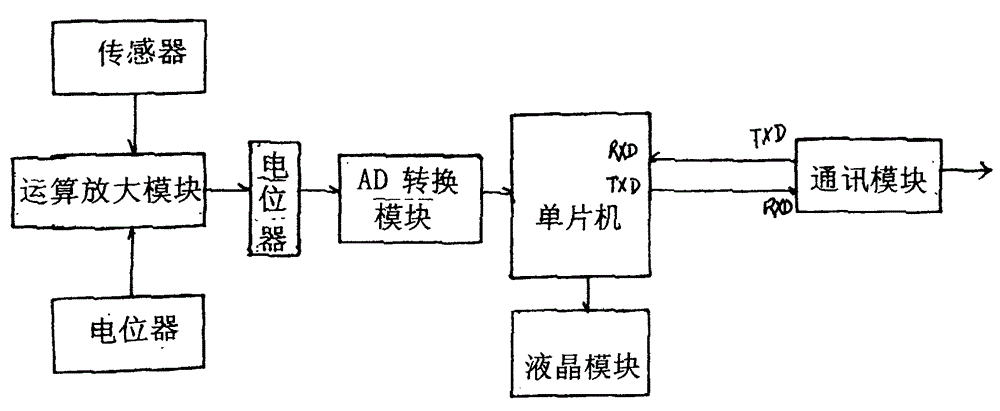

[0031] figure 1 It is the circuit principle block diagram of the existing mine pressure monitoring substation. It can be seen from the figure that it is composed of single-chip microcomputer, communication module RSM3485, AD conversion module, liquid crystal module, operational amplification module, calibration potentiometer and strain bridge pressure sensor. composition.

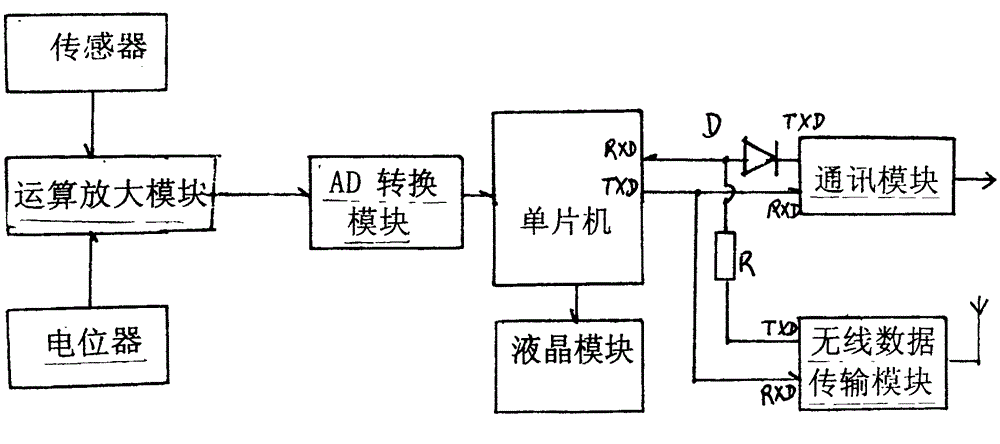

[0032] Such as figure 2 As shown, the intelligent mine pressure monitoring substation of the present invention is composed of a single-chip microcomputer U1, a communication module RSM3485, an AD conversion module, a liquid crystal module LCD1, an operation amplification module OP07BP and a strain bridge pressure sensor; it also includes a wireless data transmission module; The wireless data transmission module is a highly integrated ultra-low power consum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com