Method used for adjusting and controlling outgoing wavelength of random laser through changing thickness

A technology of random lasers and wavelengths, applied in the field of random lasers, can solve the problem that the characteristics of stimulated radiation are not easy to control, etc., and achieve the effects of simple structure, small environmental interference, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

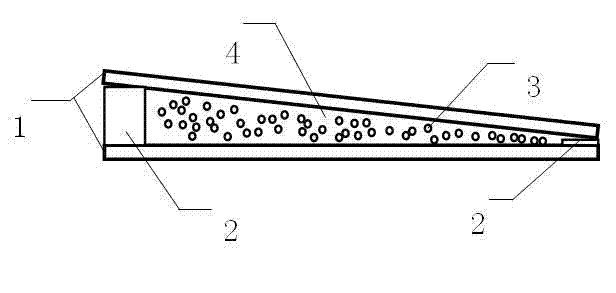

[0019] Such as figure 1 Shown: A method for adjusting the output wavelength of a random laser by changing the thickness, including the following steps:

[0020] (1) First, place two spacers 2 of different thicknesses on the two ends between the two glass substrates 1 of the random laser respectively to form a wedge-shaped sandwich structure with a gradient thickness change. The thickness range of the above two types of spacers 2 3-300μm;

[0021] (2) pouring the disordered gain medium into the wedge-shaped interlayer;

[0022] The disordered gain medium can be a liquid crystal 3 in which a laser dye solution 4 gain medium is dissolved. At this time, the glass substrate can be subjected to rubbing orientation pretreatment before making a wedge-shaped structure; at the same time, it can be made into a polymer-dispersed liquid crystal with a gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com