Low-noise temperature compensation crystal oscillator

A crystal oscillator and temperature compensation technology, applied in the direction of output stability, electrical components, etc., can solve the problem that the compensation circuit cannot accurately compensate the frequency drift of the crystal oscillator, and achieve accurate compensation, reduce noise, and improve frequency stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

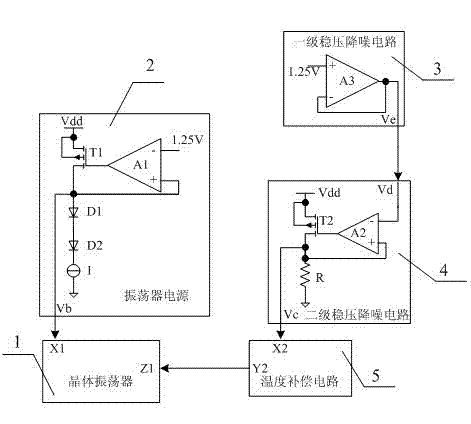

[0018] A low-noise temperature-compensated crystal oscillator includes a crystal oscillator 1, an oscillator power supply 2, a primary voltage stabilization and noise reduction circuit 3, a secondary voltage stabilization and noise reduction circuit 4, and a temperature compensation circuit 5.

[0019] The specific structure of this embodiment is as figure 1 As shown: the power supply input terminal X1 of the crystal oscillator 1 is connected to the output terminal Vb of the oscillator power supply 2, the input terminal Z1 of the crystal oscillator 1 is connected to the output terminal Y2 of the temperature compensation circuit 5, and the input terminal X2 of the temperature compensation circuit 5 It is connected with the output terminal Vc of the secondary voltage stabilization and noise reduction circuit 4 , and the input terminal Vd of the secondary voltage stabilization and noise reduction circuit 4 is connected with the output terminal Ve of the primary voltage stabilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com