Performance lamplight power supply system

A power supply system and lighting technology, which is applied in the direction of electric lamp circuit layout, light source, electric light source, etc., can solve problems such as insufficient loop power, excess loop number, and large interference range, so as to reduce the difficulty of installation and design and improve equipment utilization. , The effect of simple power supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with drawings and embodiments.

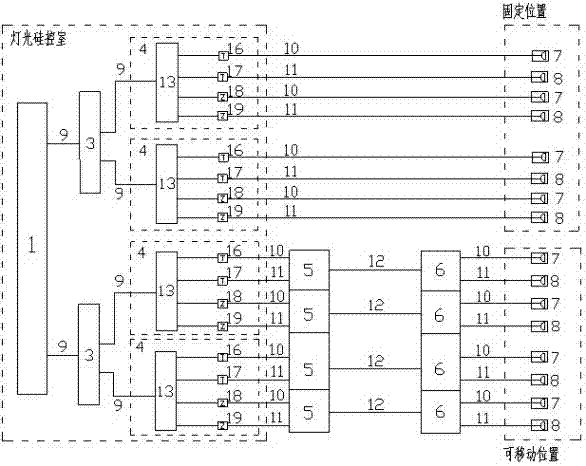

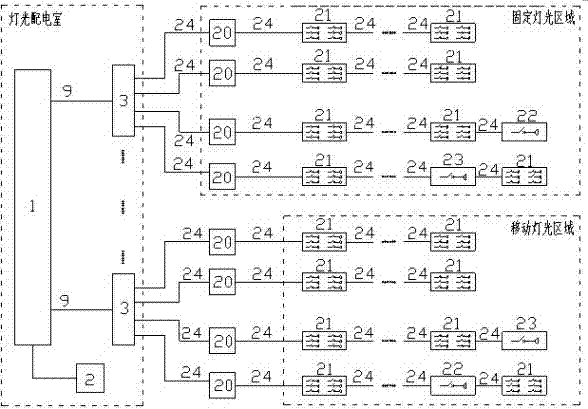

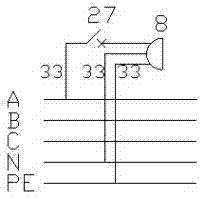

[0046] Such as figure 2 As shown, the performing arts lighting power supply system in this embodiment includes: a power distribution system and several regional distribution boxes 20, the power distribution system is used to receive external power and distribute it to each regional distribution box 20, and the regional power distribution The box 20 is used to provide power for electrical equipment (especially lighting equipment) in a predetermined power supply area. Each area distribution box 20 is connected to one or more groups of socket modules, and each group of socket modules includes one or more sockets connected in series Modules, the socket modules in the same group are not limited to be connected in series or in parallel, the specific connection method needs to be determined according to the actual power consumption situation, such as power consumption locatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com