Electrorheological fluid-based flexible controllable air sac polishing tool

An electrorheological fluid and airbag polishing technology, which is applied in the field of advanced optical manufacturing, can solve problems such as inconsistency and uneven force, and achieve the effects of controllable size, accurate correction of local surface shape, and high polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

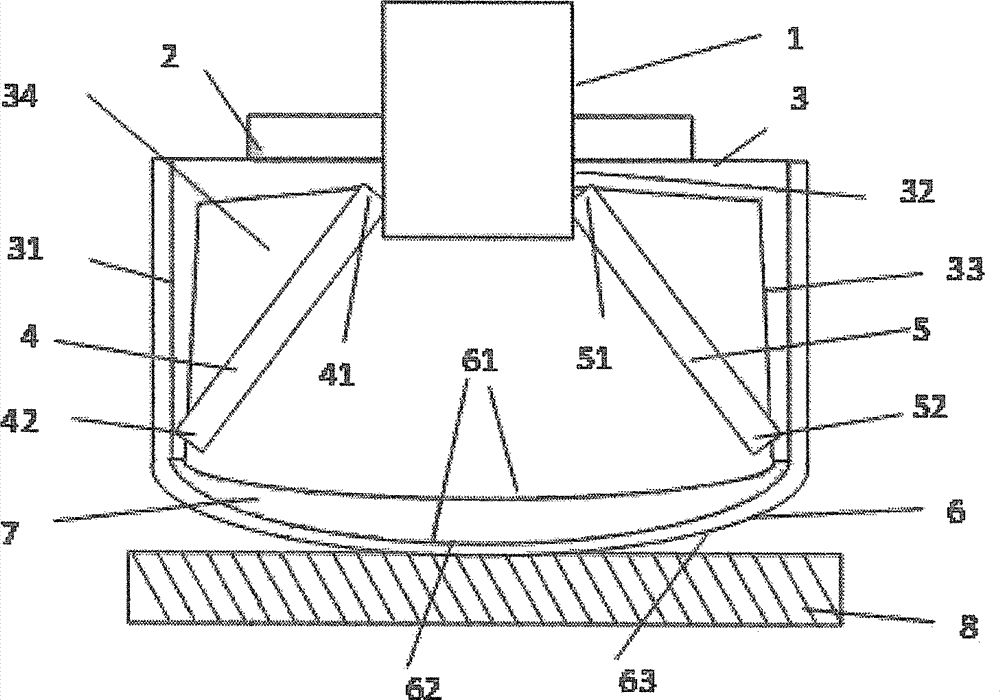

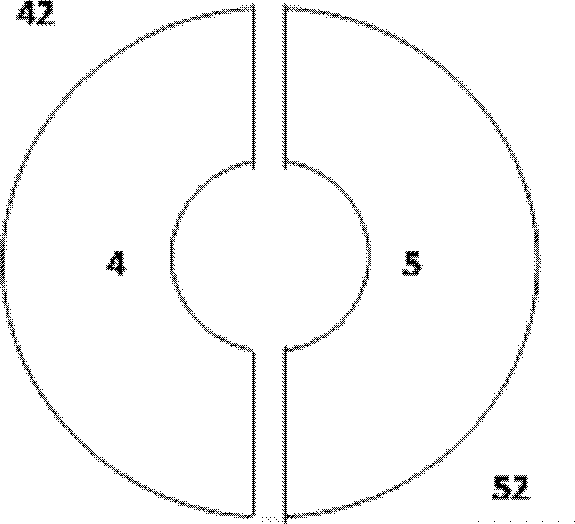

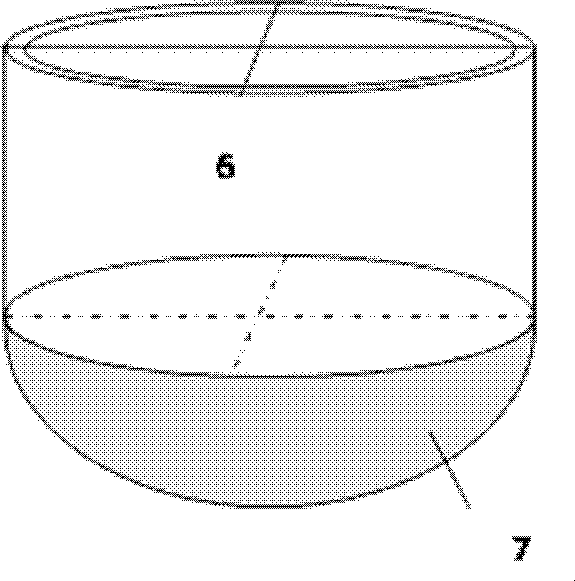

[0044] refer to figure 1 It shows a flexible and controllable airbag polishing tool based on electrorheological fluid, including a rotating shaft 1, a connecting piece 2, a rigid metal or alloy substrate 3, electrode plates 4 and 5, a hollow airbag part 6, an electrorheological fluid 7 and a workpiece to be polished 8, of which:

[0045] A base 3, which is a hollow cylinder with a lower opening, has an outer wall 31, a shaft hole 32, and an inner wall 33, and the shaft hole 32 is set at the center of the upper part of the base 3;

[0046] A connecting piece 2 has a connecting shaft hole, the connecting piece 2 is placed on the upper part of the base 3 and fixedly connected;

[0047] A rotating shaft 1, one end of which is placed in the connecting shaft hole of the connector 2 and the shaft hole 32 of the base to form a concave cavity with a closed upper end and an op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com