Differential-pressure-free dust discharging device of blast furnace gravity dust collector

A technology of gravity dust collector and pressure difference, which is applied in the direction of dust collector, etc., can solve the problems that dust and secondary pollution cannot be completely controlled, affect the physical and mental health of iron and steel enterprise workers, and easily form dust, so as to avoid secondary dust pollution and reduce Effects of gas leakage and reduction of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

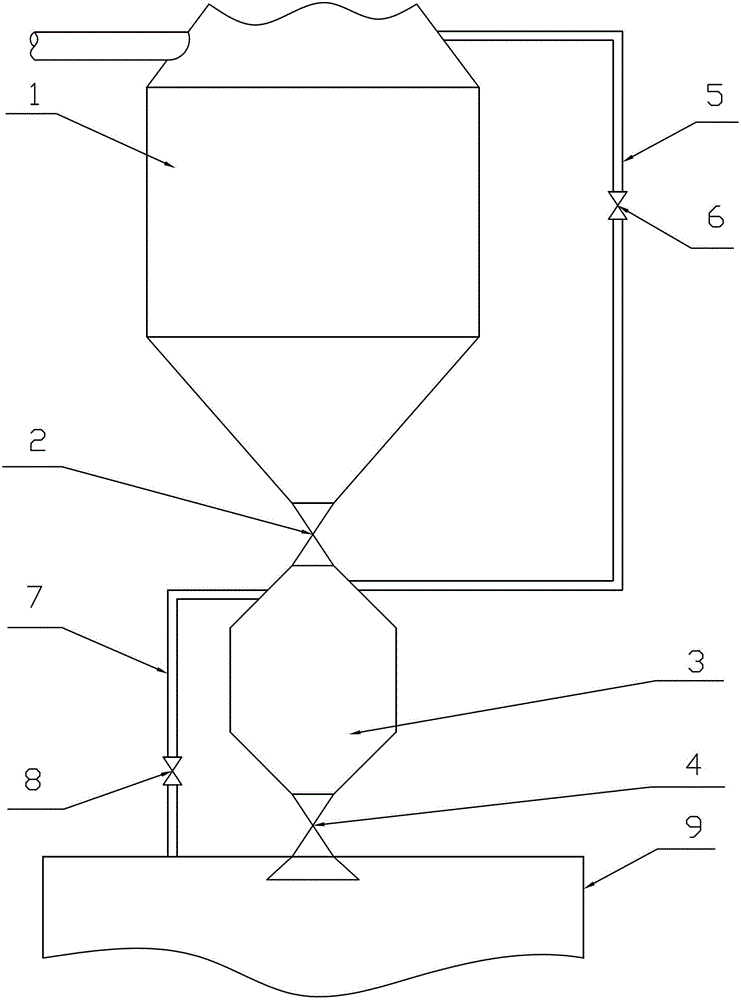

[0008] Refer to the attached figure 1 A non-pressure-difference ash-releasing device for a blast furnace gravity dust collector of the present invention will be described in detail below.

[0009] A non-pressure ash release device for a blast furnace gravity dust collector of the present invention, its structure includes a gravity dust collector 1, a ground ash bin 9 and an ash discharge valve, and the ash discharge valve includes an upper ash discharge valve 2 and a lower ash discharge valve 4 , an intermediate ash bin 3 is arranged between the gravity dust collector 1 and the ground ash bin 9, the upper ash valve 2 is arranged between the gravity dust collector 1 and the middle ash bin 3, and the lower ash valve 4 is arranged on Between the middle ash bin 3 and the ground ash bin 9, a pressure equalizing pipe 5 is arranged between the gravity dust collector 1 and the middle ash bin 3, and a pressure equalizing valve 6 is arranged on the pressure equalizing pipe 5. A release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com