Air heating furnace with nozzles in pre-burning chamber for reflowing preheating burning by opposed jetting and mixing

A technology of injection mixing and pre-combustion chamber, which is applied in furnaces, blast furnaces, heating furnaces, etc., can solve the problems of incomplete combustion, uneven mixing, large combustion chamber space, etc., and achieve the effect of increasing the local combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

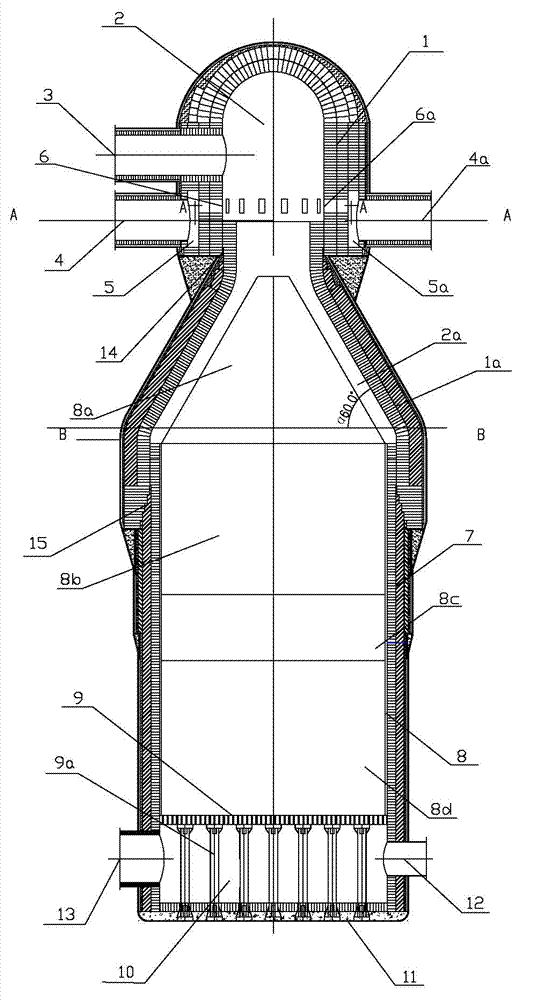

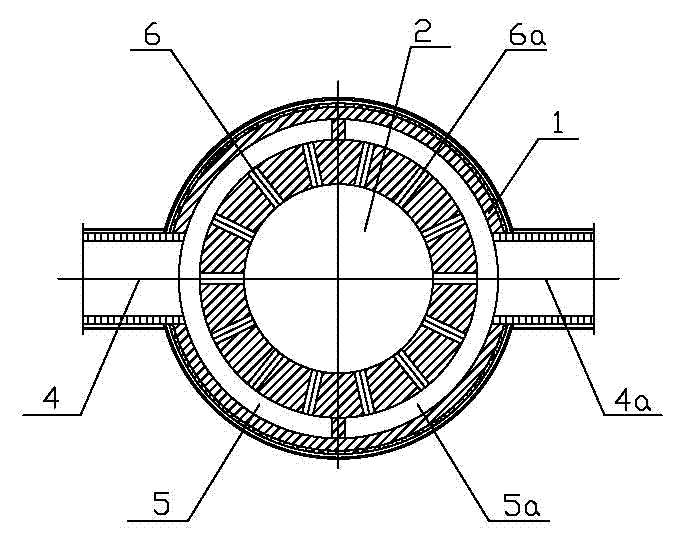

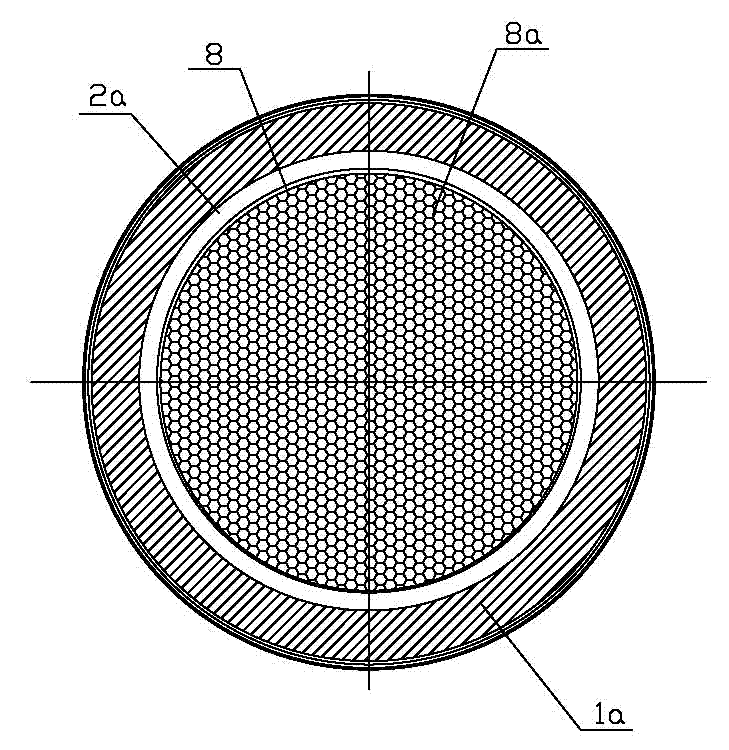

[0010] Depend on figure 1 , figure 2 and image 3 As shown, the present invention includes a pre-combustion chamber wall 1, a pre-combustion chamber 2, a combustion chamber wall 1a, a combustion chamber 2a, a hot air outlet pipe 3, a gas intake pipe 4, an air intake pipe 4a, a gas distribution loop 5, an air Distribution loop 5a, gas nozzle 6, air nozzle 6a, regenerator 8, regenerator, hot blast furnace wall 7, furnace grate 9, support column 9a, cold air chamber 10, cold air inlet pipe 12 and flue gas outlet pipe 13. The pre-chamber wall 1 is composed of the upper spherical vault and the lower cylinder. The space in the pre-chamber wall is the pre-chamber 2. The cylinder of the pre-chamber wall 1 is vertically The gas inlet pipe 4 and the air inlet pipe 4a are symmetrically arranged on the axis, and the gas inlet pipe and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com