Diffusion plate with dot-matrix diffusion structures and backlight module utilizing same

A diffusion structure and diffusion plate technology, which is applied in the field of diffusion plates, can solve the problems of low production feasibility and uneven light output of dot matrix LEDs, and achieve the effect of improving the uneven distribution of singular light and dark

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

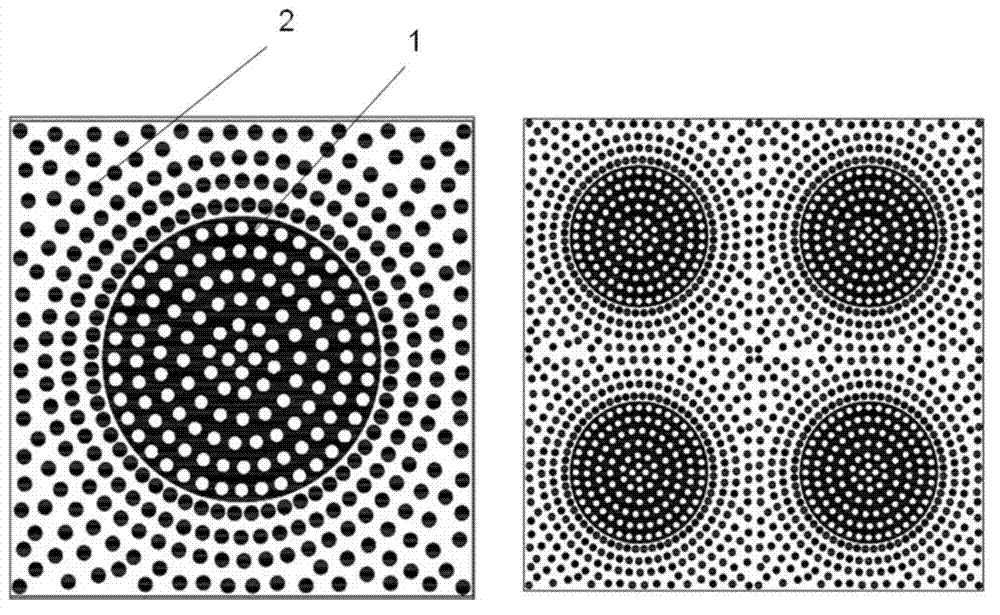

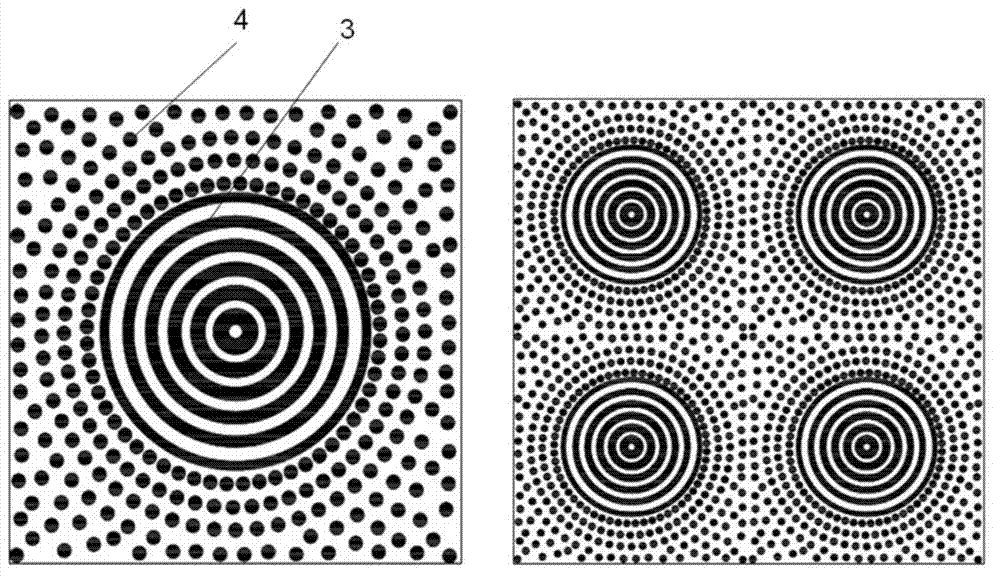

[0034] In this embodiment, a single matrix diffusion structure and 4 matrix lattice diffusion structures, and the speckle pattern as dots are used for illustration. The diffusion plate is provided with a dot-matrix diffusion structure, and the center of the dot-matrix diffusion structure corresponds to the light source center of the backlight one by one.

[0035] The diffusion structure includes two structures:

[0036] Such as figure 1 As shown, the central area of structure one is a disc 1, and the disc 1 is provided with hollow spots arranged in concentric rings, and the outside of the central area is solid spots 2 arranged in concentric rings, wherein the solid spots and non-hollow spot areas of the disk are coated with diffusion structures.

[0037] Such as figure 2 As shown, the central area of structure 2 is rings 3 arranged in concentric rings, and the outside of the central area is solid spots 4 arranged in concentric rings, wherein the rings 3 and the solid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com