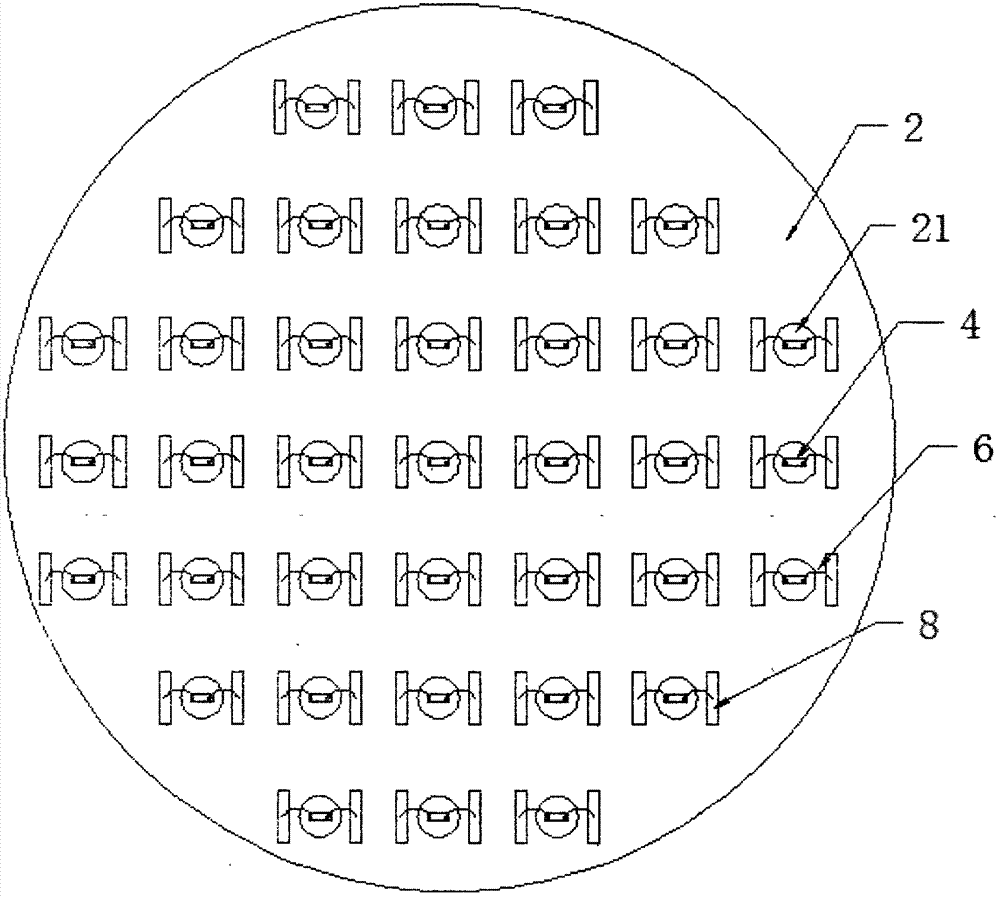

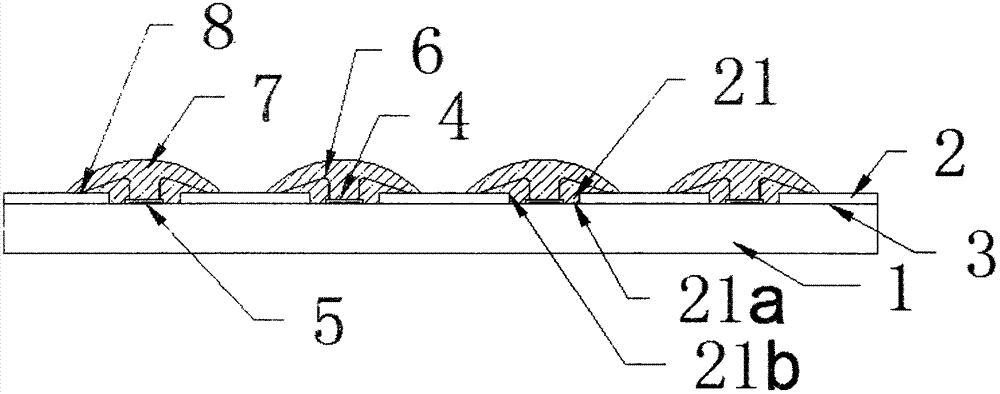

High-light-efficiency and high-thermal-conductivity LED COB light source packaging structure and manufacture process thereof

A technology of packaging structure and manufacturing process, applied in the field of LED COB light source packaging structure and manufacturing process, can solve the problems of poor heat dissipation effect, high production cost, reduced light efficiency, etc. The effect of uniform luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

[0020] The present invention has a high light efficiency and high thermal conductivity LED COB light source packaging structure and its manufacturing process. It has a metal heat dissipation plate and a thin circuit board. The metal heat dissipation plate and the thinner circuit board are pressed together, and the bottom of the small round hole of the circuit board is mirror-finished, and the inner wall of the small round hole is electroplated, and the lines are wired in series and parallel. Set the welding wire position; each chip is placed on the small round hole of the metal circuit board, and connected to the wire bonding position of the circuit board with the corresponding wire; the silica gel mixed with phosphor powder is sealed on the chip, wire and circuit board The inner point of the small hole is raised; the bottom of the metal heat sink can be bonded to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com