Pipeline hose

A pipeline type and hose technology, which is applied in the direction of hoses, pipeline layout, pipes/pipe joints/fittings, etc. It can solve the problems of decreased strength of the foamed resin layer, damage to the shape retention of the hose, and a decrease in the heat insulation performance of the hose, etc. Achieve the effect of suppression of ventilation resistance, maintenance of shape retention, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

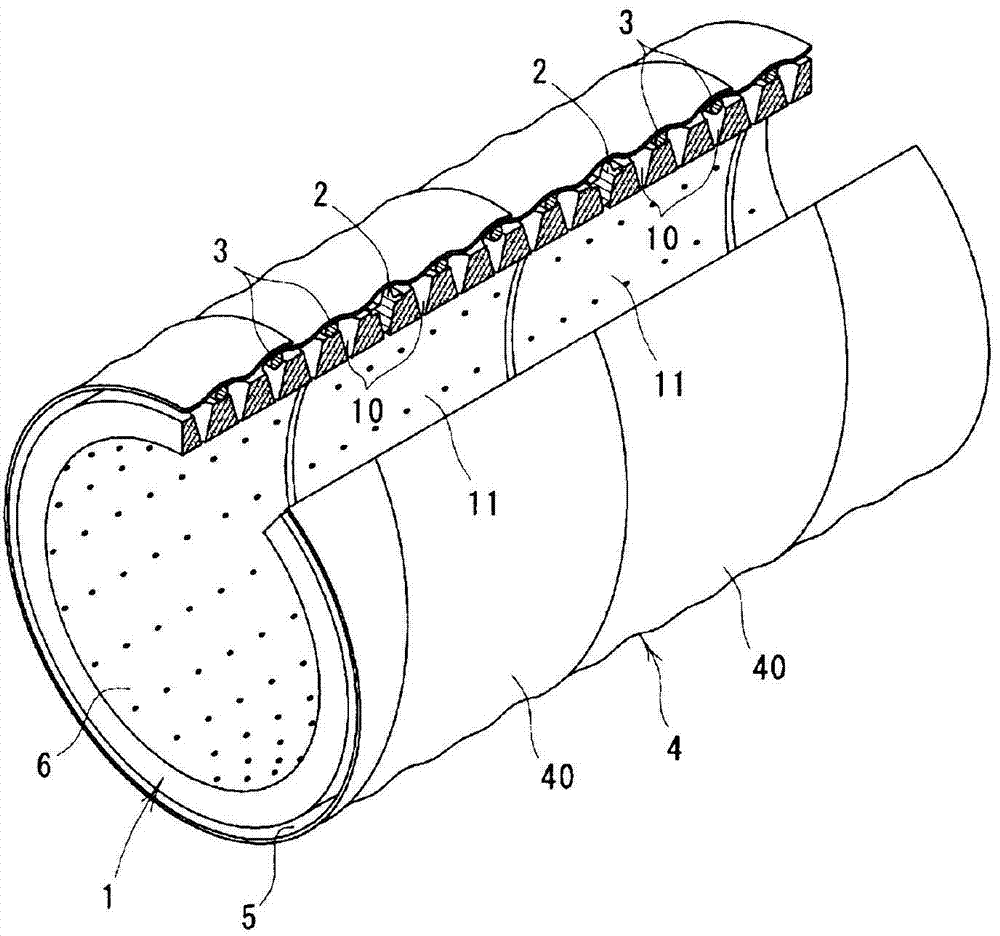

[0036] The ducted hose of the first embodiment of the present invention is connected to the supply and exhaust ports of refrigeration and heating devices such as houses or buildings, or connected to the supply and discharge ports of ventilation devices, and is used as a connection to these air conditioners. For exhaust.

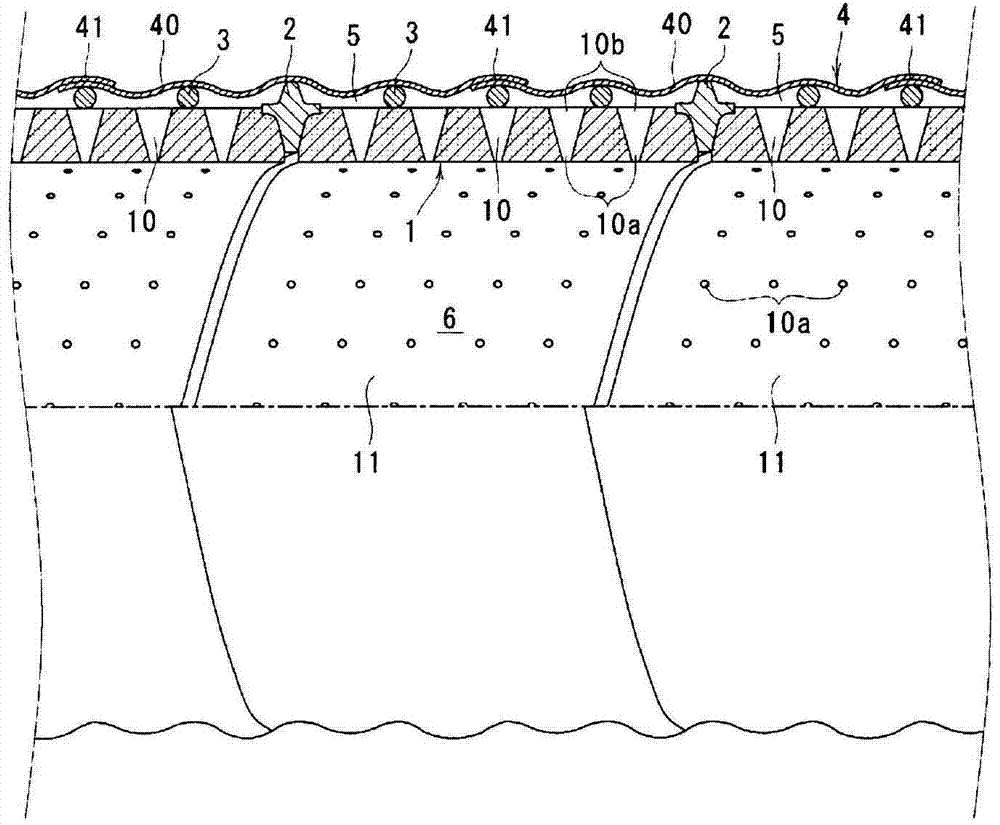

[0037] The pipeline hose such as Figure 1 to Figure 3 As shown in FIG. , thereby forming a structure in which a void portion 5 is formed between the outer peripheral surface of the inner layer 1 and the inner peripheral surface of the outer layer 4 . The duct-type hose has flexibility as a whole, and allows gas (air for supplying and exhausting air) to flow through the internal space 6 surrounded by the inner peripheral surface of the inner layer 1 .

[0038]In the inner layer 1, a plurality of sound-absorbing holes 10 having a substantially V-shaped cross-section are formed penetrating in the radial direction of the hose at appropriate intervals in the ax...

no. 2 approach

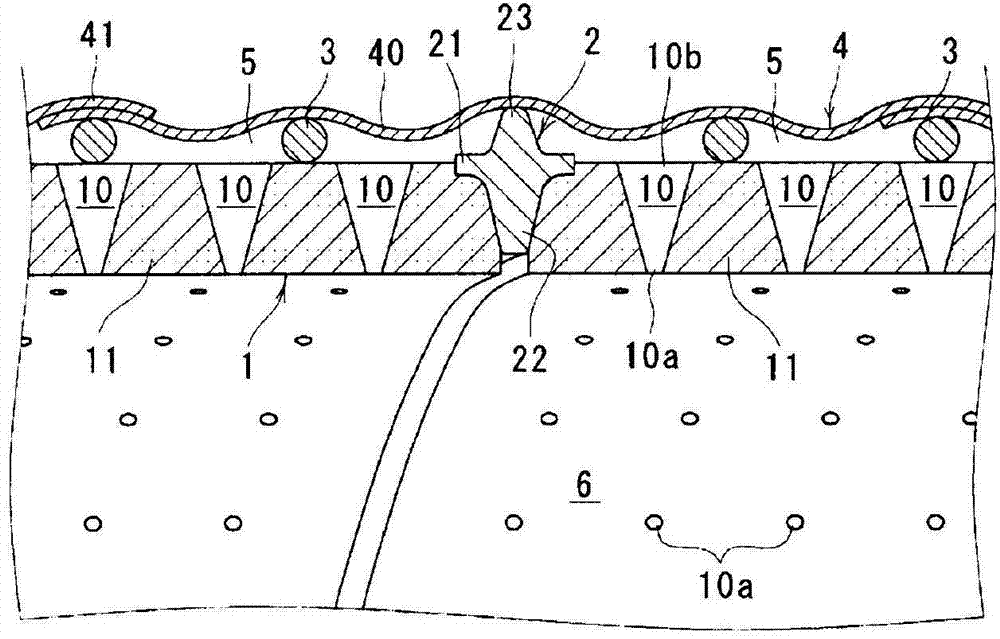

[0055] The pipeline type hose of the second embodiment of the present invention such as Figure 6 to Figure 8 As shown, the reinforcing core material 2 is formed in a substantially T-shaped cross section having a horizontal piece 21 and a vertical piece 22 . Furthermore, an elastic spacer 50 for pushing the outer layer 4 outward in the hose radial direction is attached to the outer peripheral surface of the horizontal piece 21 of the reinforcing core material 2 .

[0056] The elastic spacer 50 is made of, for example, foamed polyethylene resin, and its width is wider than that of the transverse sheet 21 of the reinforcing core material 2, and is formed in a roughly rectangular cross-section with a thickness of about 3 mm, covering and concealing the transverse sheet 21. , and wound into a helical shape along the outer peripheral surface of the horizontal piece 21. In addition, the joint portion 41 between the adjacent edge portions of the soft resin sheet 40 in the outer laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com