Double-storage bin submerged arc welding agent circulating device

A technology of circulating device and submerged arc flux, applied in arc welding equipment, welding equipment, welding accessories, etc., can solve the inconvenience of installation, use and maintenance of flux circulating device, affect the applicability of flux circulating device and welding equipment, and stabilize flux circulating It can solve problems such as poor performance and reliability, and achieve the effect of stable and reliable transportation, recovery and circulation process, improving the convenience and applicability of installation and use, and improving the efficiency of flux recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

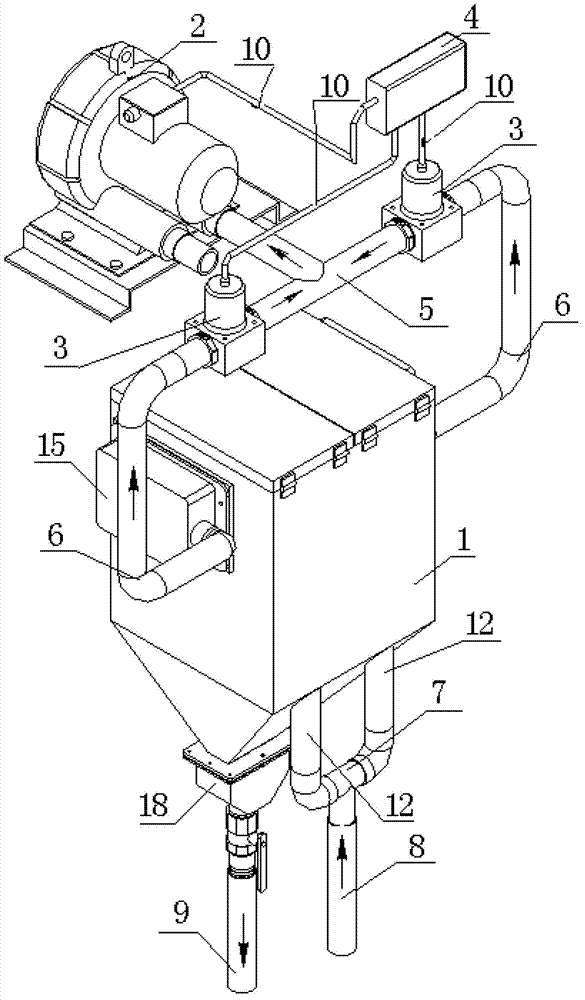

[0025] Embodiment 1: Taking a double-silo submerged arc flux circulation device used in a storage tank horizontal submerged arc welding equipment as an example, the present invention will be further described in detail.

[0026] refer to figure 1 . The double-silo submerged-arc flux circulation device of the present invention includes a double-silo flux barrel 1, a high-pressure fan 2, a two-position solenoid valve 3, a fan solenoid valve controller 4, an air suction tee 5, an air suction hose 6, and a feeding three Pass 7, flux recovery hose 8, flux supply hose 9, signal line 10.

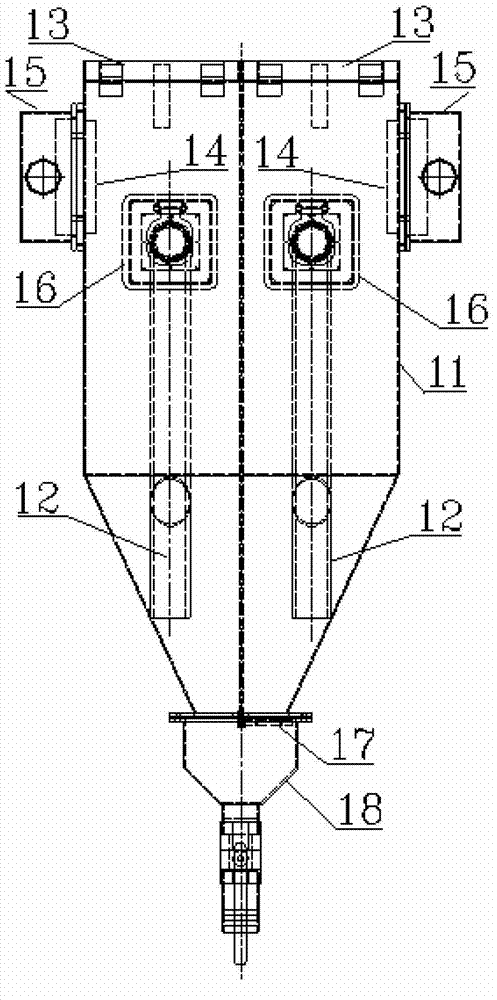

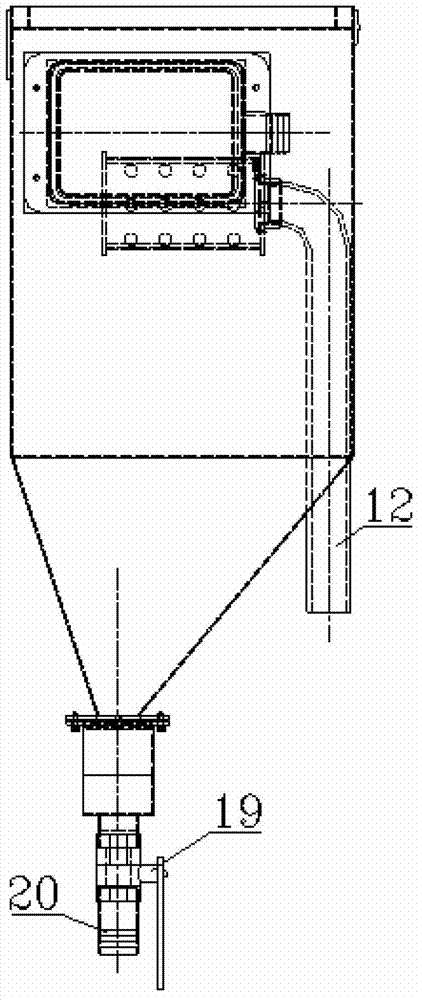

[0027] refer to Figure 2a with 2b . The double-silo flux barrel 1 is composed of a flux barrel body 11, a material suction elbow 12, a barrel cover 13, an air filter element 14, a filter element gland 15, a flux filter assembly 16, a blanking baffle 17, and a small blanking chamber 18 , Ball valve 19 and hose joint 20. The flux barrel 11 is welded by steel plates. The upper part of the flux ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com