Method and device for treating sewage

A sewage and sewage treatment technology, applied in the direction of chemical instruments and methods, sustainable biological treatment, water/sewage multi-stage treatment, etc., to achieve the effect of shortening the cycle, improving the quality of life and happiness index, and saving human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

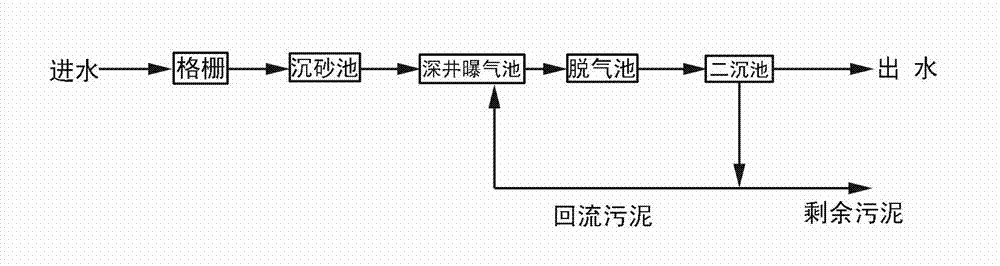

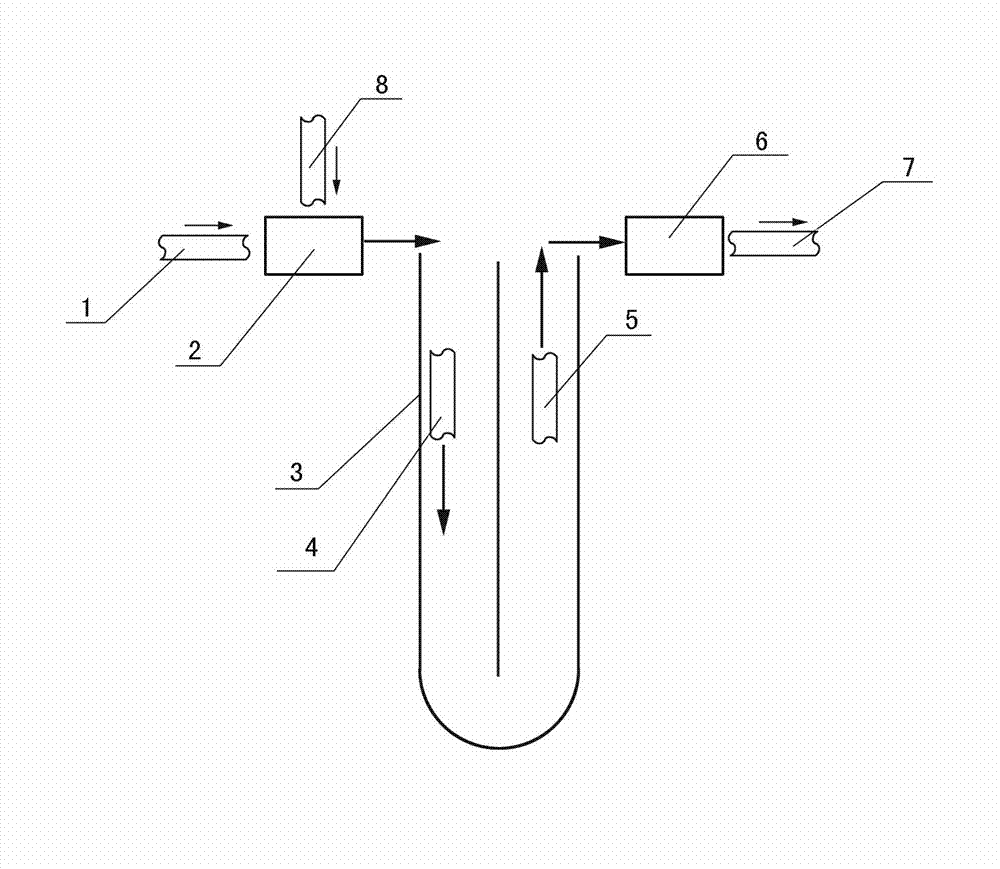

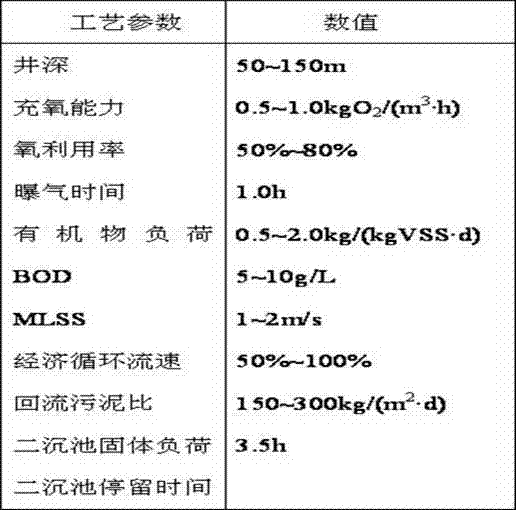

[0014] As shown in Fig. 1 and Fig. 2, the method and device for treating sewage in the present invention transform the scrapped coal mine shaft shaft into a deep aeration shaft for sewage treatment, and add a new aeration shaft in the shaft shaft for sewage treatment after transformation. Isolation steel plate and downpipe 4, riser pipe 5, water inlet pipe 1, head water tank 2, degassing pool 6, outlet pipe 7, sludge return pipe 8 are arranged on the top, and deep well aeration wells are arranged outside the shaft of the mine shaft wall 3.

[0015] The present invention is a technical method and device for treating sewage. Its technological process is as follows: the raw sewage enters the head water tank 2 through the grid and the grit chamber, and after being fully mixed with the return sludge, enters the downcomer 4 in the shaft of the mine shaft. , there is a downward aeration head in the downcomer 4 to oxygenate the circulating water body, the sewage from the shaft of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com