Method for estimating inner surface temperature of blast furnaces

A technology for estimating the temperature and inner surface, which is applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems that the surface temperature of blast furnaces cannot be directly measured, achieve good economic and social benefits, improve the quality of blast furnace smelting, and have strong adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

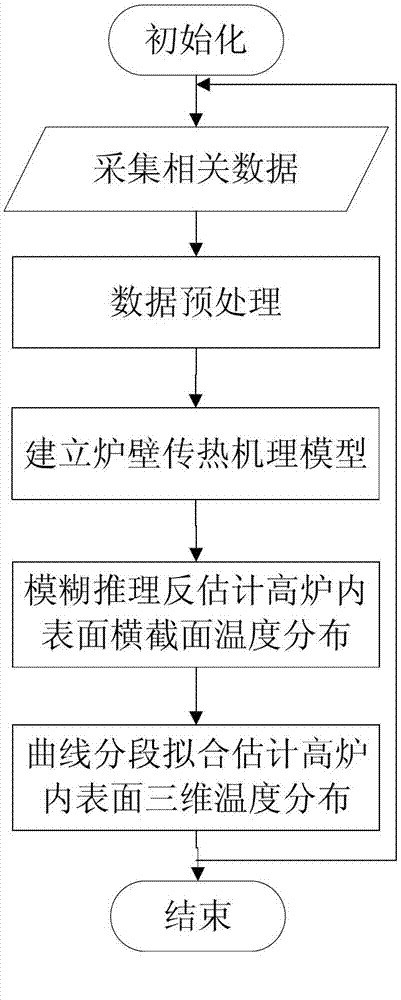

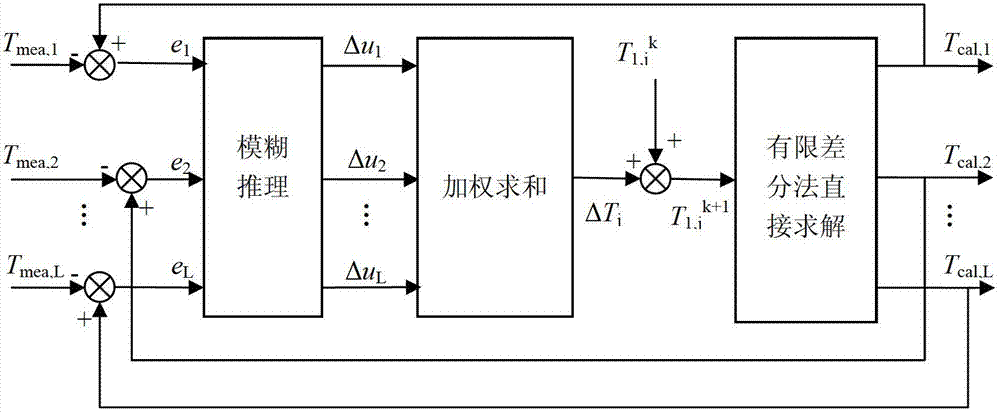

[0022] see figure 1 , the sequence of the method for estimating the blast furnace inner surface temperature in the present invention includes the following steps: (1) data collection and preprocessing; (2) establishing a furnace wall heat transfer mechanism model; (3) obtaining the cross-sectional temperature of the blast furnace inner surface at different heights; (4) ) to estimate the three-dimensional temperature distribution on the inner surface of the blast furnace.

[0023] Each step is described in detail as follows:

[0024] 1. Data collection and preprocessing:

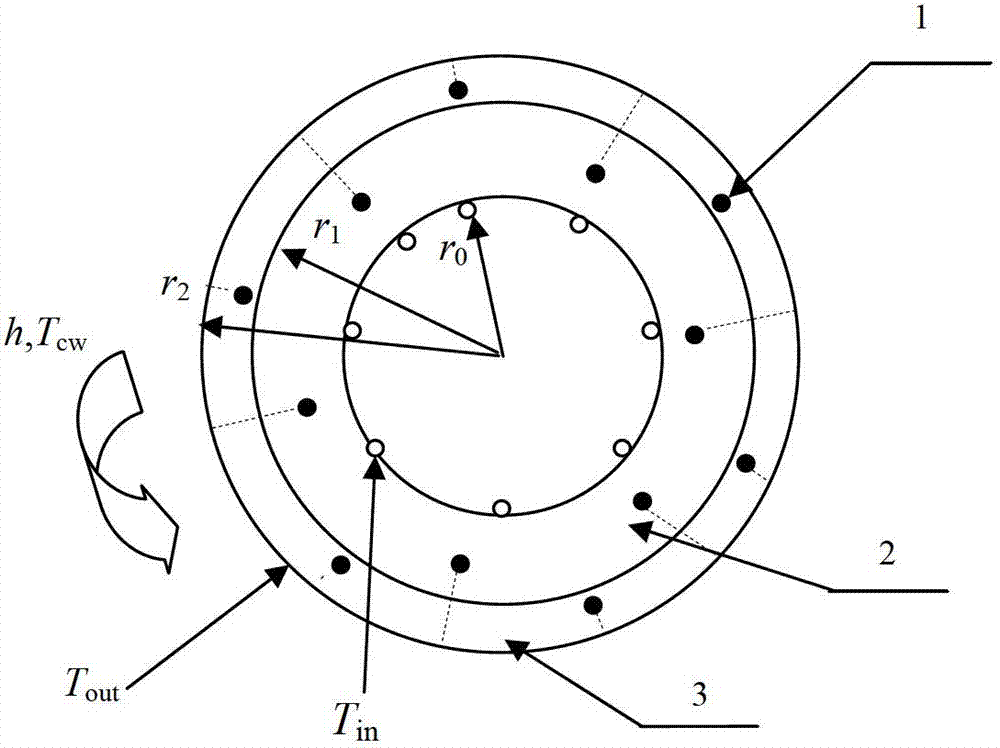

[0025] There are high temperature, high pressure and corrosive substances inside the blast furnace. The temperature of most points on the inner wall of the blast furnace cannot be directly measured, and it is difficult to directly obtain the temperature distribution of the inner surface of the blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com