Smelting method of steel for hypoxia axle

A technology for axle steel and smelting methods, applied to the improvement of process efficiency, furnace type, furnace, etc., can solve the problems of large fluctuations in the quality of axle steel, oxygen content and inclusion control levels that are difficult to achieve stably, and improve comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

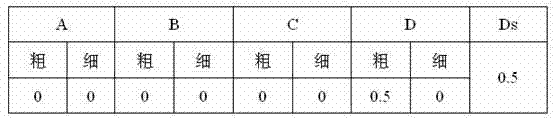

Image

Examples

Embodiment

[0047] What the present embodiment produces is high-speed motor car axle steel, and the mass percent of its composition and the requirement of oxygen content are as follows:

[0048] C 0.20~0.30%; Si 0.15~0.40%; Mn 0.50~0.80%; P≤0.020%;

[0049] S≤0.015%; Cr 0.90~1.20%; Mo 0.20~0.30%; V ≤0.06%;

[0050] Al ≤0.050%; [O] ≤20×10 -6 . The rest is Fe and unavoidable impurities.

[0051] This embodiment is the following sequential steps:

[0052] 1 Electric furnace smelting

[0053](1) Electric furnace charging: firstly put 6 tons of high-quality steel scrap into the electric furnace, the scrap steel (weight) P≤0.025%, S≤0.030%, the surface of the scrap steel is dry, free of oil and impurities, and the overall size is ≤800mm×500mm. Then pour 54 tons of the pretreated molten iron into the electric furnace, put the pretreated molten iron into the furnace (weight) P 0.060%, S 0.040%, and the temperature of the molten iron is 1260°C.

[0054] (2) Oxygen blowing in the electric f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com