Method for preparing moisture absorption, deodorization and ultraviolet resistance fabric

An anti-ultraviolet and fabric technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of difficult mass production, unstable fabric functionality, and inefficiency, and achieve simple implementation, compact preparation, and process arrange reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

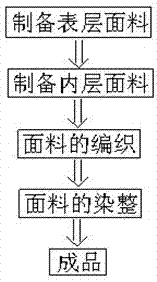

Image

Examples

Embodiment

[0016] The specific preparation method is as follows:

[0017] a) Prepare the surface layer fabric, the surface layer fabric is a blended fabric of 14.3tex ramie fiber and long-staple cotton fiber, and its blending ratio is 50%-56%, 44%-50%; the surface layer fabric adopts the spinning technology of AB yarn. Ramie fiber strips with an average length of about 82 mm are blended with long-staple cotton fiber strips with an average length of about 40 mm. Wet fast, antibacterial, anti-mildew, anti-ultraviolet and other characteristics, and the yarn fibers are thick and thin, long and short, rigid and soft, learning from each other.

[0018] b) Prepare the inner layer fabric, the raw material of the inner layer fabric is polyester filament, the specification is: 8.52tex / 72 f; the inner layer fabric is prepared by knitting process, and its knitting density is about 50*60, and the formed inner layer fabric , the thickness is about 0.18-0.22mm. The raw material of the inner fabric ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com