Rectangular waveguide directional coupler

A technology of directional coupler and rectangular waveguide, which is applied in the direction of waveguide devices, electrical components, connecting devices, etc., can solve the problems of high insertion loss, reduced directivity, and narrow bandwidth, and achieve large power capacity, low insertion loss, and increased directional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

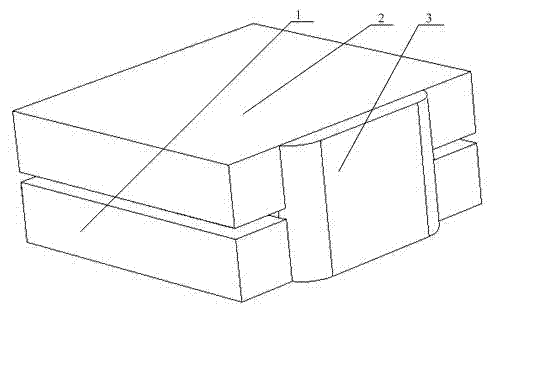

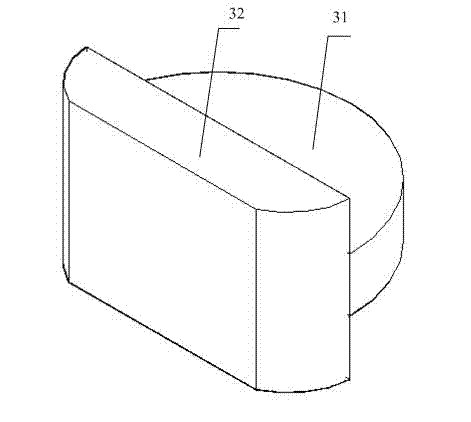

[0044] Such as Figure 4 , 5 As shown, this embodiment includes a main rectangular waveguide 1 and a sub-rectangular waveguide 2. The main rectangular waveguide 1 is a microwave main channel, and the sub-rectangular waveguide 2 is a sampling signal channel; the main rectangular waveguide 1 and the sub-rectangular waveguide 2 have main modes H The surfaces are parallel to each other, the main rectangular waveguide 1 and the auxiliary rectangular waveguide 2 are isolated from each other, and there is a coupling hole 3 including a hollow coupling tube 32 attached to the side wall of the main rectangular waveguide 1 or the side wall of the auxiliary rectangular waveguide 2. 32. The side wall close to the rectangular waveguide 1 is connected to a three-end open coupling cavity 31. The coupling cavity 31 is connected to the hollow coupling tube 32. The coupling cavity 31 is located between the main rectangular waveguide 1 and the auxiliary rectangular waveguide 2 and is connected to th...

Embodiment 2

[0046] Such as Image 6 As shown, the difference from the first embodiment is that the main rectangular waveguide 1 and the secondary rectangular waveguide 2 are parallel, and there is no angle. The coupling holes 3 are only partly inside the main rectangular waveguide 1 and the sub-rectangular waveguide 2, and partly outside. No columnar metal body 7 is provided in the coupling hole 3.

Embodiment 3

[0048] Such as Figure 7 As shown, the difference from the first embodiment is that the main rectangular waveguide 1 and the sub-rectangular waveguide 2 are connected through two coupling holes 3, and the centers of the two coupling holes 3 are respectively located at the intersection of the main rectangular waveguide 1 and the sub-rectangular waveguide 2 Near the two opposite vertices of the parallelogram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com