Method for producing a carbon brush in a commutator

A commutator, carbon brush technology, applied in brush manufacturing, current collectors, rotary current collectors, etc., can solve the problems of carbon brush resistance increase and change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

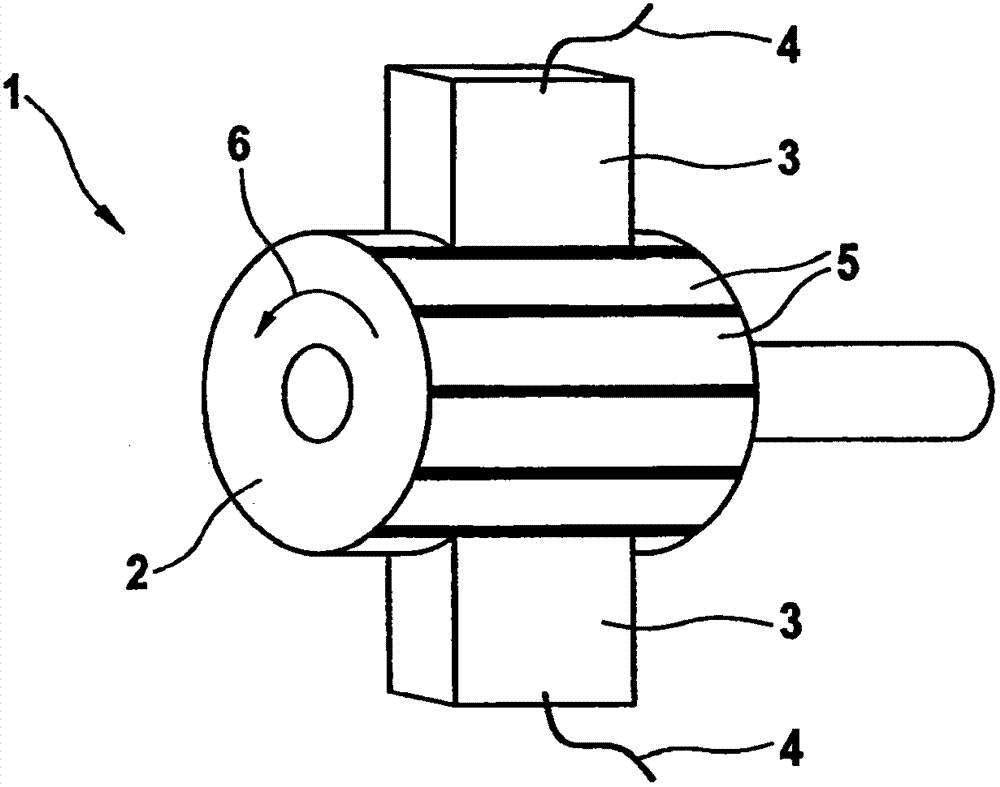

[0017] figure 1 The current collector 1 shown is used for the transmission and commutation of electric current in an electric machine, such as an electric motor or a generator, and is preferably used for a starter of an internal combustion engine. Such starters are designed for extensive starting operations, especially in the case of motor vehicles equipped with a start-stop system for automatically switching off and switching on the internal combustion engine.

[0018] The commutator 1 comprises a cylindrical current collector 2 which is non-rotatably connected to the armature of the electric machine, the armature being rotatably mounted in the stator. Furthermore, the commutator 1 comprises a plurality of carbon brushes 3 which, in the exemplary embodiment shown, are in contact with diametrically opposite radially outer peripheral surfaces or a The rolling surface of the disk transmits the current introduced into the corresponding carbon brush 3 via the twisted wire 4 to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap