Cutter head deep-loosening stubble-ploughing rotary tillage multifunctional machine

A multi-functional machine and subsoiling technology, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of damage to the transmission box assembly, difficult maintenance, and long time consumption, and achieve reasonable structural design, convenient replacement and operation, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

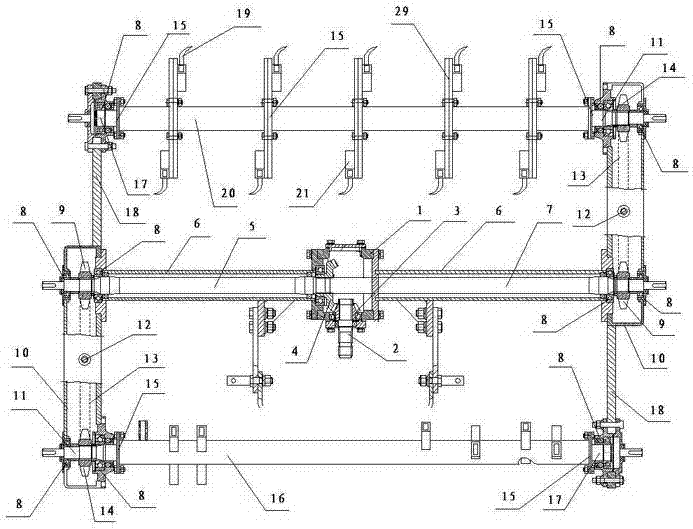

[0040] Embodiment 1, with reference to figure 1 , a multi-functional rotary tillage machine for subsoiling and stubble removal with cutter head, which includes a transmission box assembly arranged on the side and a gearbox assembly arranged in the middle, and the gearbox body 1 of the gearbox assembly is provided with a tractor power output The connected power input spline shaft 2; the power input spline shaft 2 in the gearbox body 1 is provided with an input bevel gear 3;

[0041] The transmission box assembly includes a coulter transmission box assembly and a subsoiler transmission box assembly. A coulter drive shaft 5 and a subsoiler drive shaft 7 are provided, and both the coulter drive shaft 5 and the subsoiler drive shaft 7 are connected to the power transmission bevel gear 4 located in the gearbox body 1, and the power transmission bevel gear 4 meshes with the input bevel gear 3;

[0042] Both the coulter transmission box assembly and the subsoiler transmission box as...

Embodiment 2

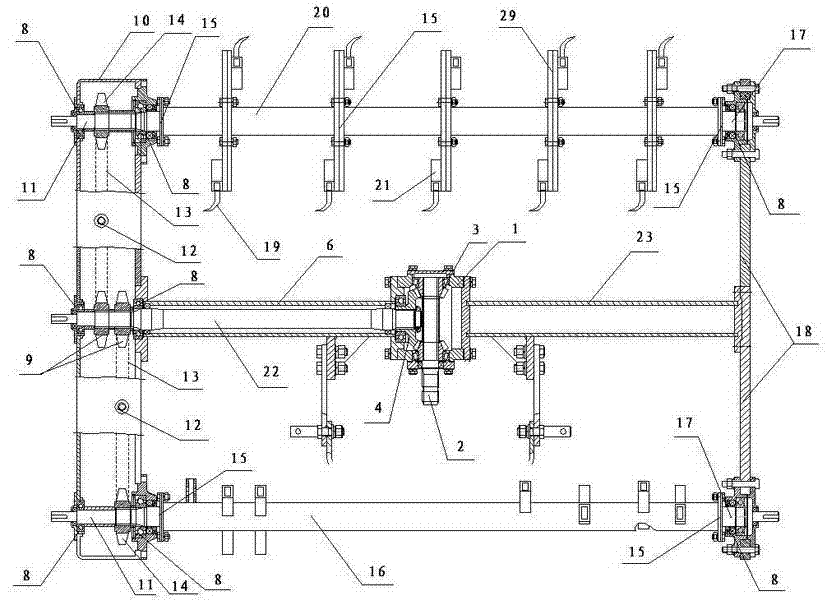

[0045] Embodiment 2, with reference to figure 2 , a multi-functional rotary tillage machine for subsoiling and stubble removal with cutter head, which includes a transmission box assembly arranged on the side and a gearbox assembly arranged in the middle, and the gearbox body 1 of the gearbox assembly is provided with a tractor power output The connected power input spline shaft 2; the power input spline shaft 2 in the gearbox body 1 is provided with an input bevel gear 3;

[0046] The transmission box assembly includes a transmission box body 10, which is connected to one side of the gearbox assembly through the support arm housing 6, and a power transmission shaft 22 is arranged in the support arm housing 6, and one end of the power transmission shaft 22 It extends into the transmission case 10, and the other end is connected to the power transmission bevel gear 4 provided in the gearbox body 1, and the power transmission bevel gear 4 meshes with the input bevel gear 3;

...

Embodiment 3

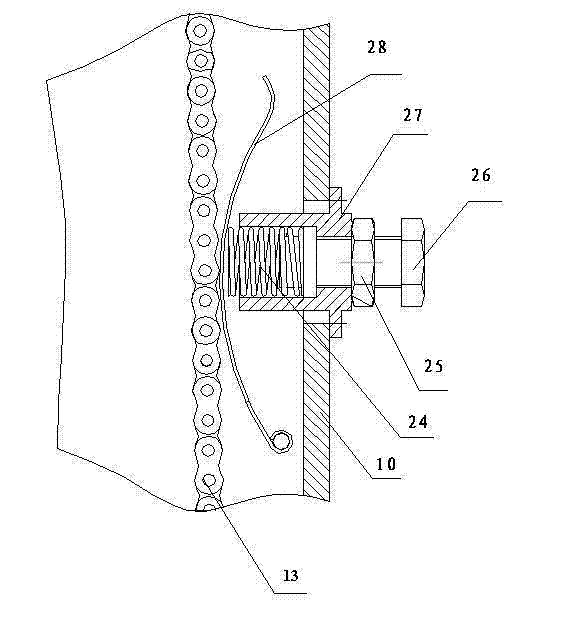

[0050] Embodiment 3, in embodiment 1 or 2 described cutter disc subsoiling stubble removal multifunction machine: described subsoiling cutter shaft 20 is divided into several sections, and the two ends of each subsoiling cutter shaft 20 are provided with There is a flange 15, and the connected flange 15 is used as a subsoiling cutter head 29.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com